Method for on-line monitoring of mechanical fault of on-load tap-changer of transformer

A technology for on-load tap change and mechanical failure, which is applied in the direction of instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc. It can solve the problems of low failure rate, small number of tap changer actions, and insufficient research, so as to achieve applicability Good, high accuracy, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

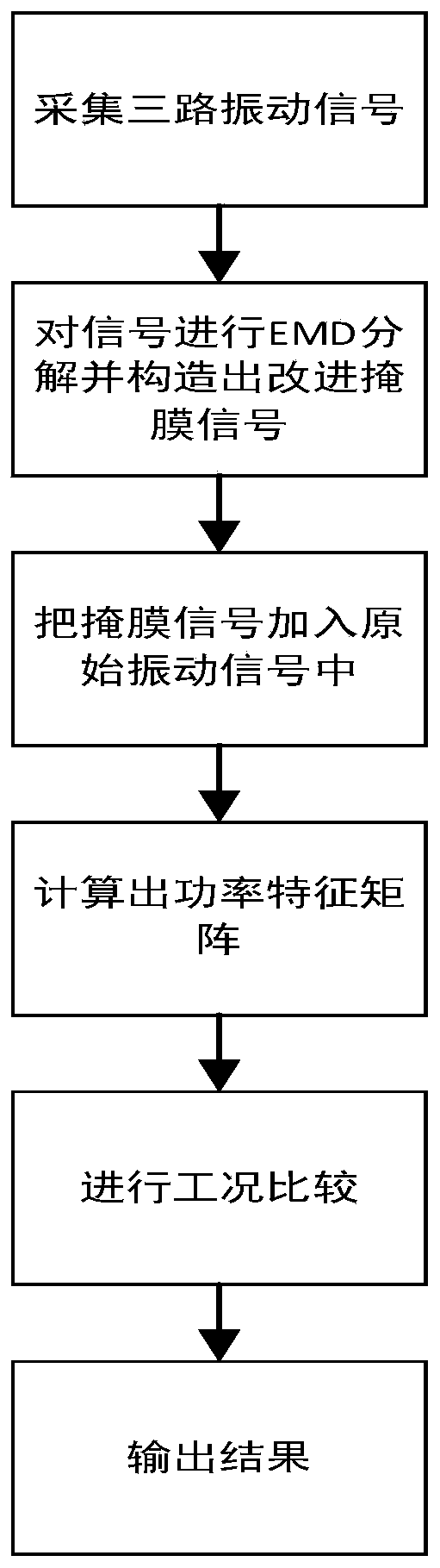

[0052] The invention provides a method for on-line monitoring of mechanical faults of transformer on-load tap-changers. For the specific process, see figure 1 , the method includes the following steps: Step 1: stick p vibration sensors on the top of the tank wall of the on-load tap-changer OLTC, and collect vibration signals generated during the operation of the on-load tap-changer;

[0053] In a preferred embodiment of the present application, p=3, that is, three vibration sensors are pasted on the top of the tank wall of the on-load tap changer OLTC.

[0054] The vibration sensor is placed on the vertical top of the OLTC, because the contact mechanism and the top are directly connected rigidly, and all the collected vibration signals can contain all the characteristic quantities.

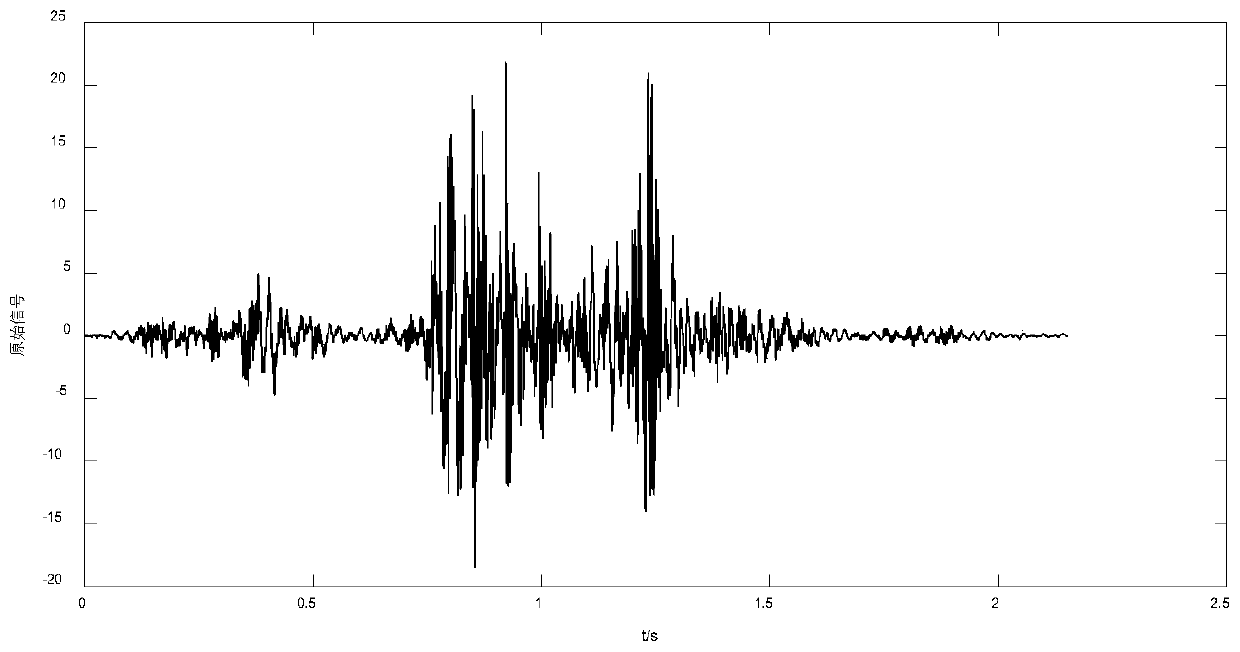

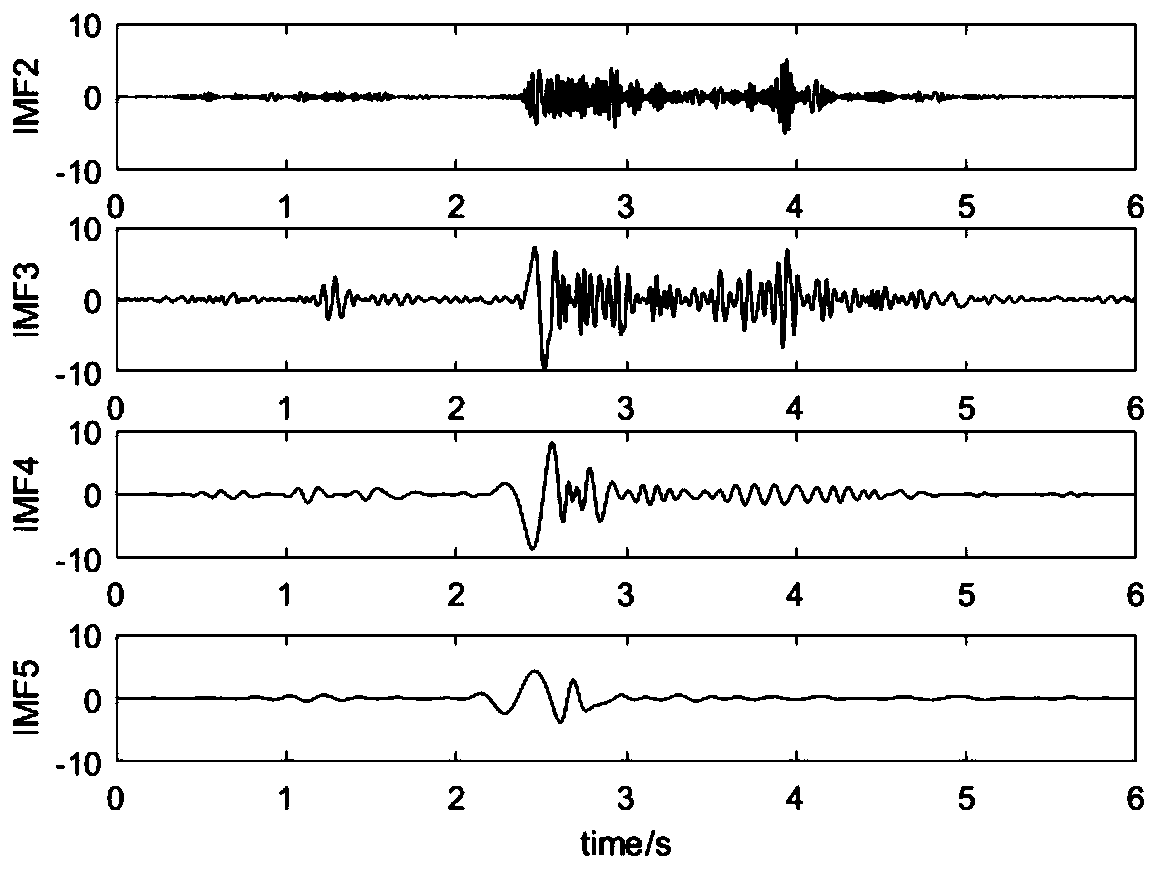

[0055] Step 2: Perform empirical mode decomposition EMD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com