High-sensitivity automatic optical detection method and device

An automatic optical detection and high-sensitivity technology, which is applied in the direction of optical testing of flaws/defects, material analysis through optical means, and measuring devices, etc. It can solve problems such as film color differences and complex manufacturing processes, achieve high sensitivity, and improve image capture efficiency , Efficient and flexible detection and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0069] see figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the first aspect of the embodiment of the present invention provides a high-sensitivity automatic optical detection method, which includes the following steps:

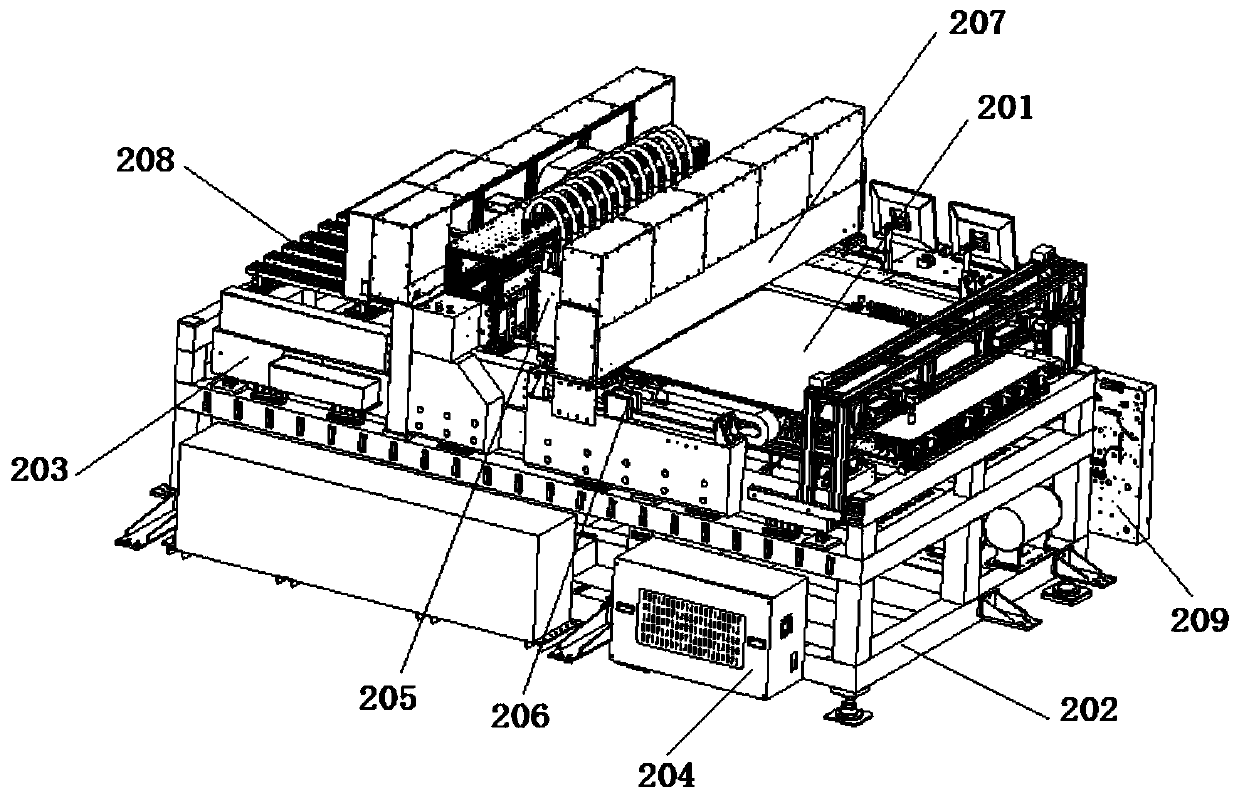

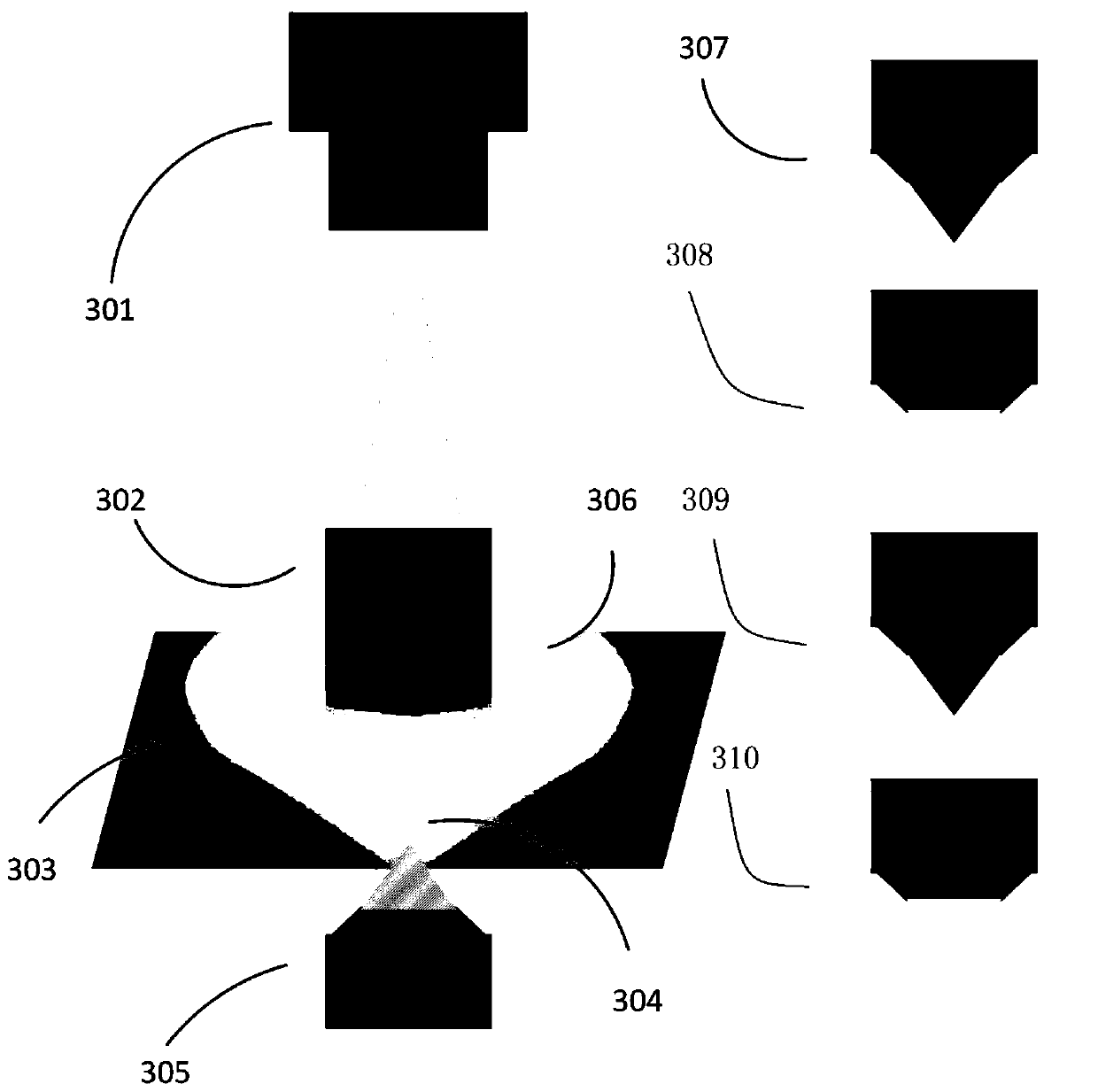

[0070] Step 1: According to the set imaging sequence of various imaging modes, the camera 301 continuously moves and shoots on the flat sample 201 according to the preset motion trajectory, and collects images of various imaging modes of the flat sample 201. The motion trajectory is based on actual needs and the specific shape of the flat sample 201; and there is a partial overlapping area between two adjacent images of the same imaging mode, of course, there is also an overlapping area between images of multiple imaging modes in one scan, and there is no need to reverse Direction The flat sample 201 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com