A motor multi-eccentric fault simulation method and device

A fault simulation device and fault simulation technology, applied in the direction of motor generator testing, etc., can solve problems such as complicated operation and difficult in-depth diagnosis of motor eccentricity fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

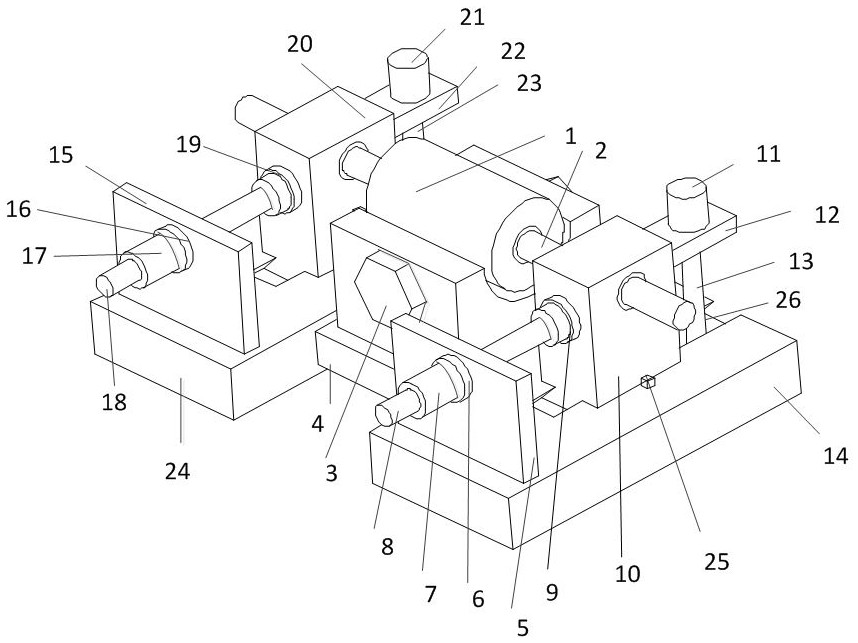

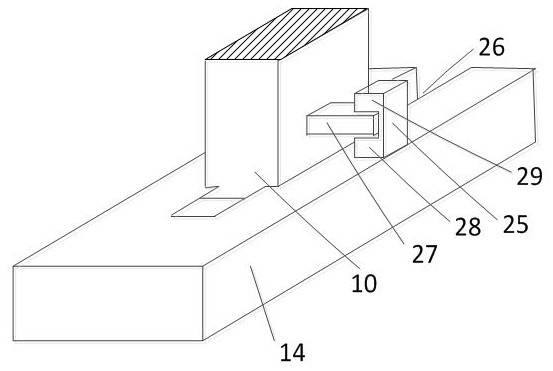

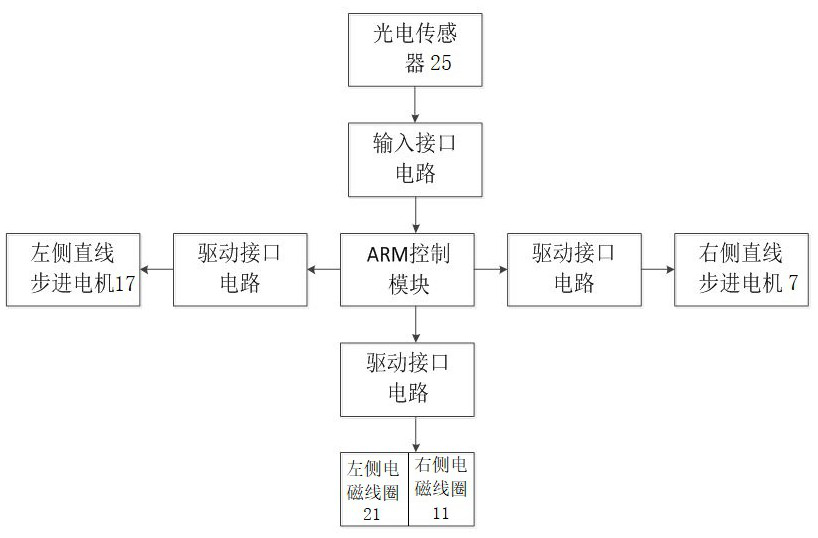

[0021] Referring to Figure 1, the test motor 1 itself is horizontally arranged on the left and right, and placed on the semicircular seat 4 of the test motor. A motor multi-eccentric fault dynamic simulation device of the present invention is symmetrically arranged on both sides along the axial direction of the test motor 1, and the structures and installation methods of the two sides are completely the same. The bottoms on the left and right sides are respectively horizontal bases, which are respectively the left base 24 and the right base 14 with the same structure. The top of each base is fixedly connected with a vertical linear stepping motor support, and the left base 24 is fixed respectively. Connect the left linear stepping motor support 15, and the right base 14 is fixedly connected with the right linear stepping motor support 5. The left base 24 and the right base 14 are on the left and right sides of the semicircular base 4 and are fixedly connected with the semicirc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com