A battery-based heat-sealing mold for shell cover

A battery and mold technology, which is applied in the direction of lead-acid battery, battery cover/end cover, lead-acid battery construction, etc., can solve the problems of poor accuracy, small application range of the lower mold, and easy sliding of the upper mold, so as to avoid accumulation, The effect of ensuring accuracy and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

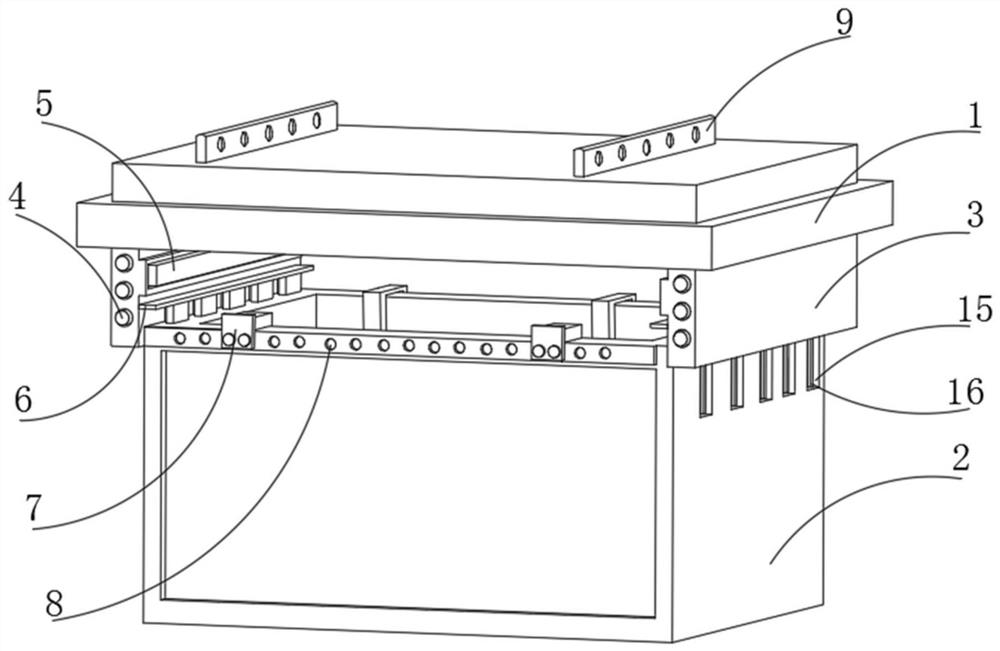

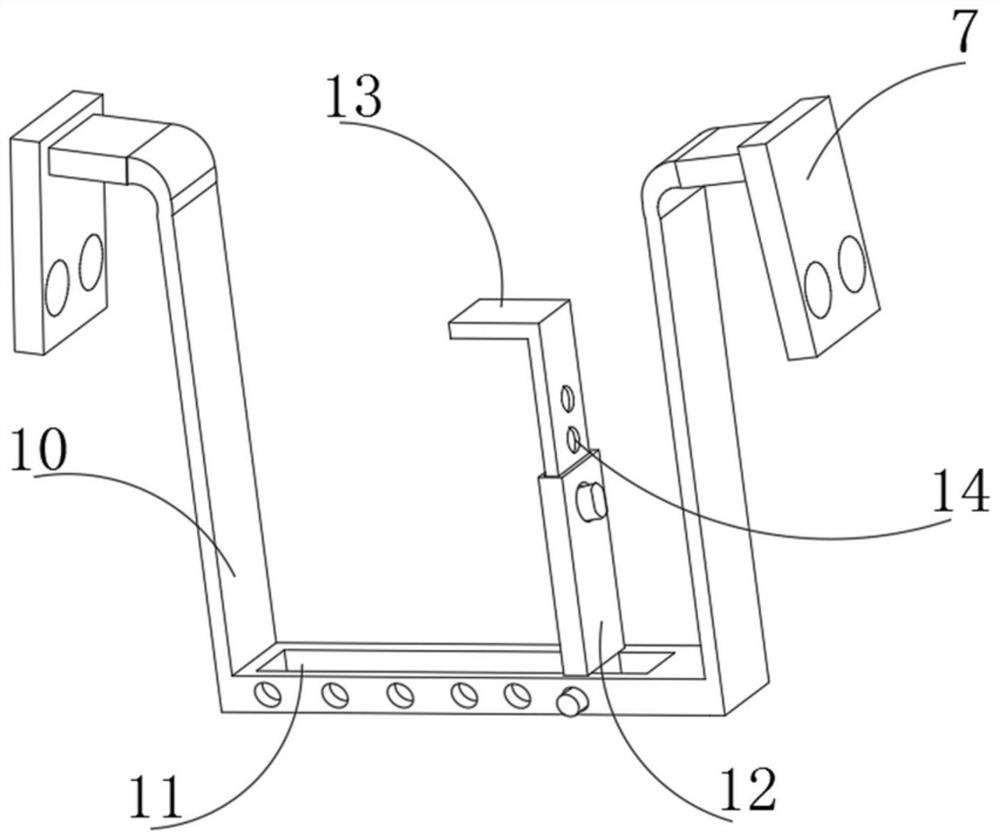

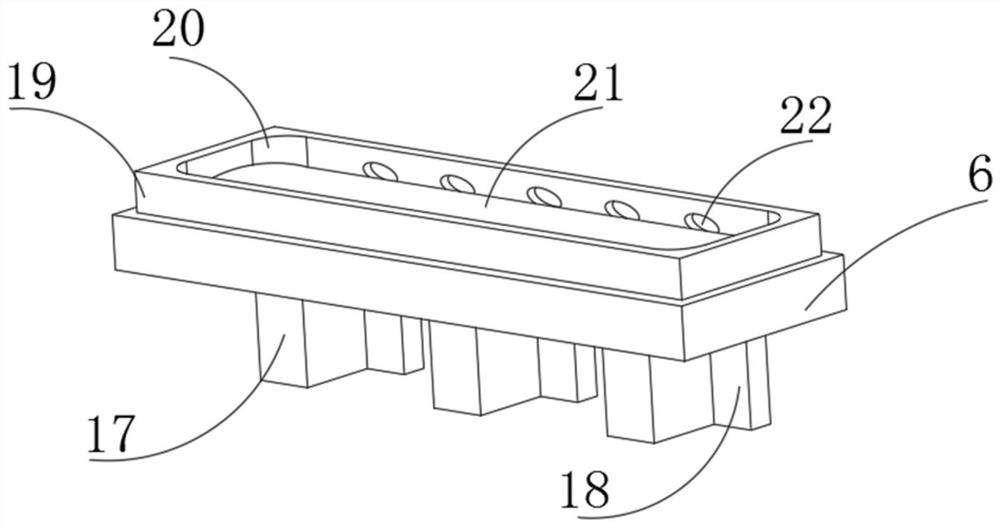

[0021] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a battery cover heat-sealing mold, including an upper mold 1, the battery cover can be fixed and installed through a fixing groove, and a fixing groove is opened inside the upper mold 1, and through fixing The bolt holes inside the plate 9 can be fixedly connected to the top of the upper mold 1 and the lifting device of the heat sealing machine, so as to improve the firmness of the installation of the upper mold 1 when it falls. Both sides of the top of the upper mold 1 are equipped with a fixed plate 9, and Bolt holes are evenly opened inside the fixed plate 9, the lower mold 2 is installed on one side of the upper mold 1, and the partition plate 3 is installed on both sides of the bottom of the upper mold 1, and the electric heating cylinder 4 is embedded in the partition plate 3, and the electric heating cylinder 4 The model is EC6002, a heat conduction plate 5 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com