Manual and automatic integrated return oil filter

A filter and an integrated technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of oil spill, filter area reduction, soaking, etc., and achieve the effect of easy oil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

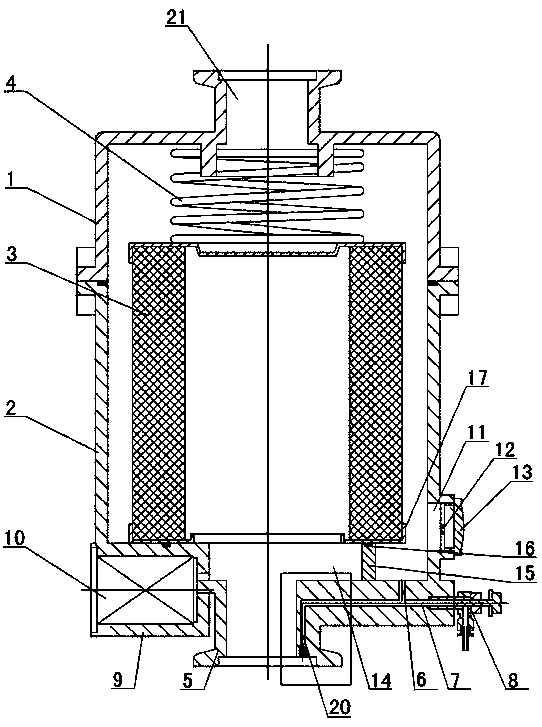

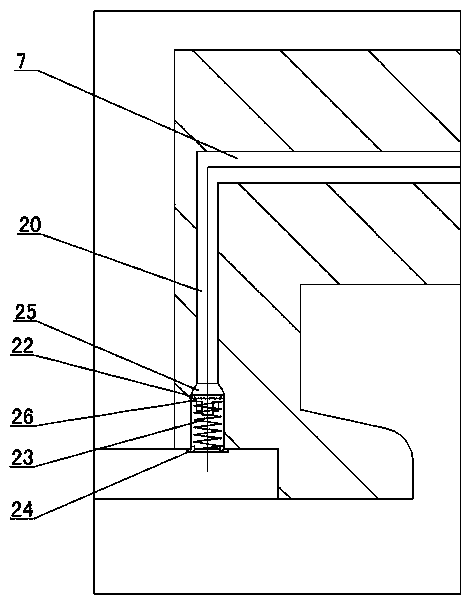

[0009] The invention relates to a manual and automatic oil return oil mist filter, such as figure 1 , figure 2 As shown, it includes an upper housing 1 and a lower housing 2, a filter element 3 is arranged between the upper and lower housings, an air outlet 21 is provided on the upper housing 1, and an air inlet 5 is provided in the lower part of the lower housing 2 An oil return mechanism is provided at the air interface, and the oil return mechanism includes an annular boss 15 provided on the inner bottom surface of the lower housing 2, an oil storage groove 14 is formed in the annular boss, and a vertical oil return hole 6 is provided at the bottom of the lower housing 2. The inner end of the horizontal oil return hole 7 and the horizontal oil return hole 7 is provided with an automatic oil return port 20. The automatic oil return port 20 is connected to the oil storage tank of the vacuum pump. The automatic oil return port 20 is equipped with an automatic oil-sealing oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com