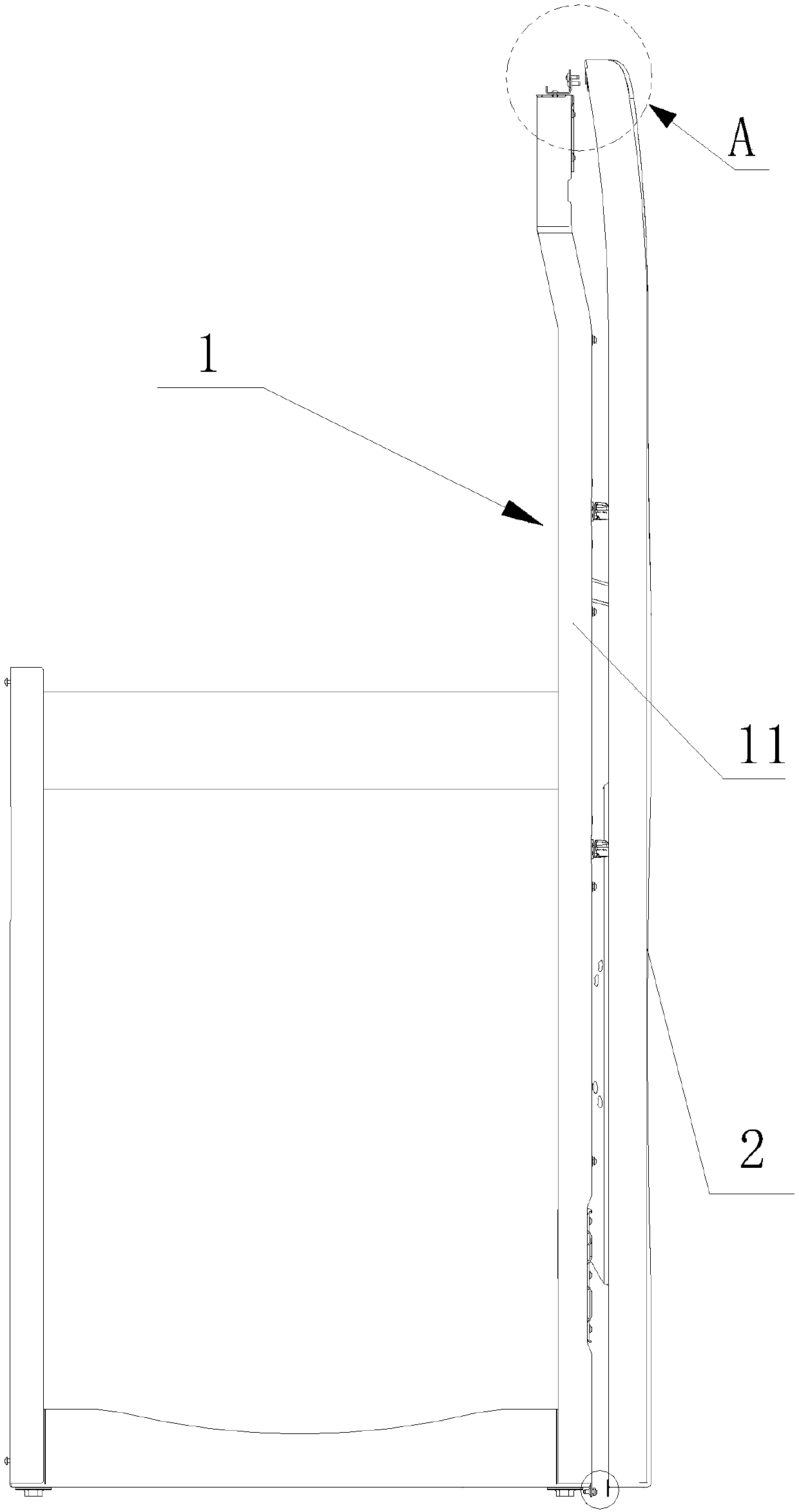

Clothes treatment equipment

A kind of clothing processing equipment and clothing technology, which is applied in other washing machines, household clothes dryers, textiles and papermaking, etc., can solve the problems of unsightly appearance, poor structural stability, and structural design affecting home appliances, etc., and achieve the effect of simplifying the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

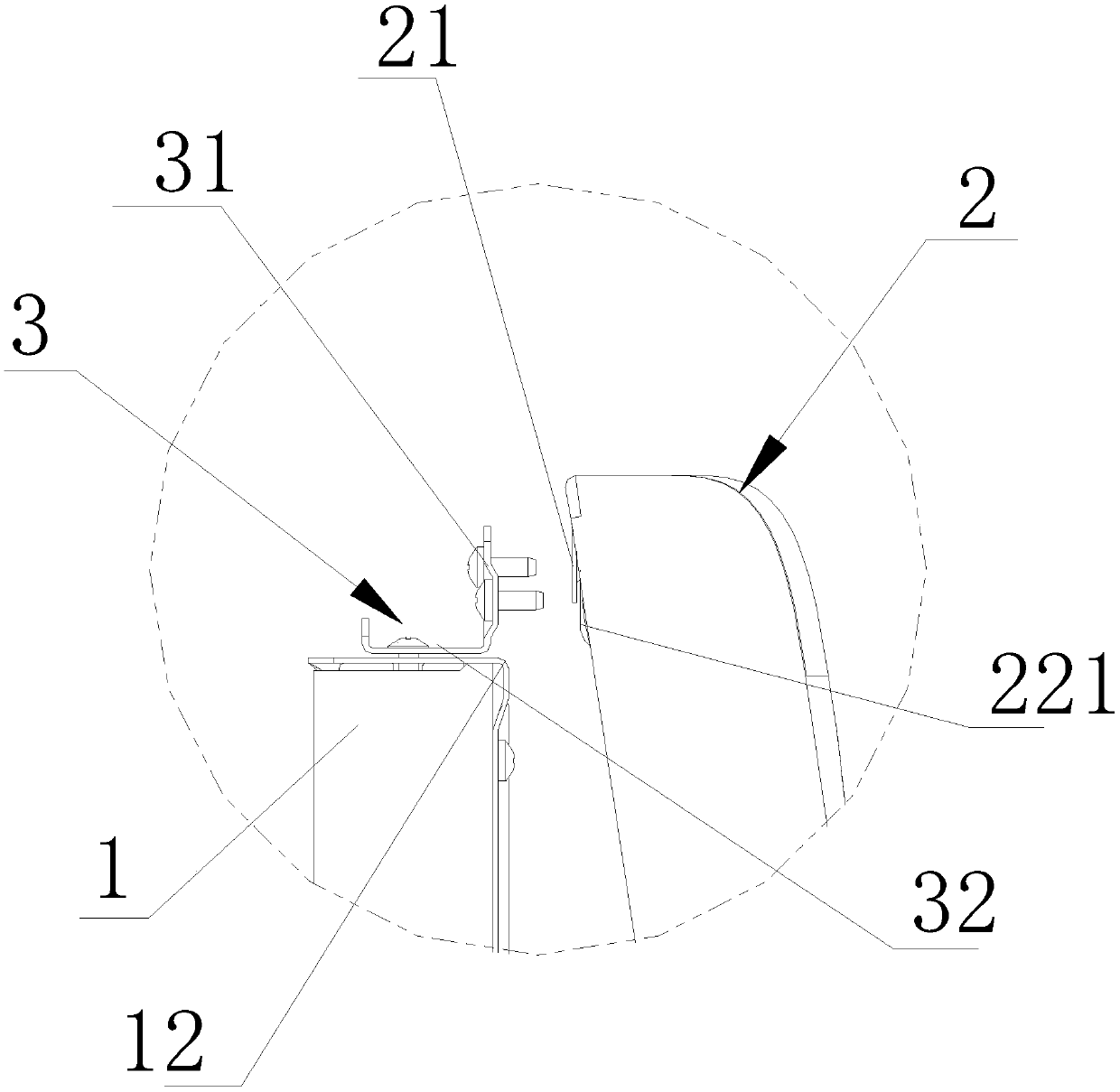

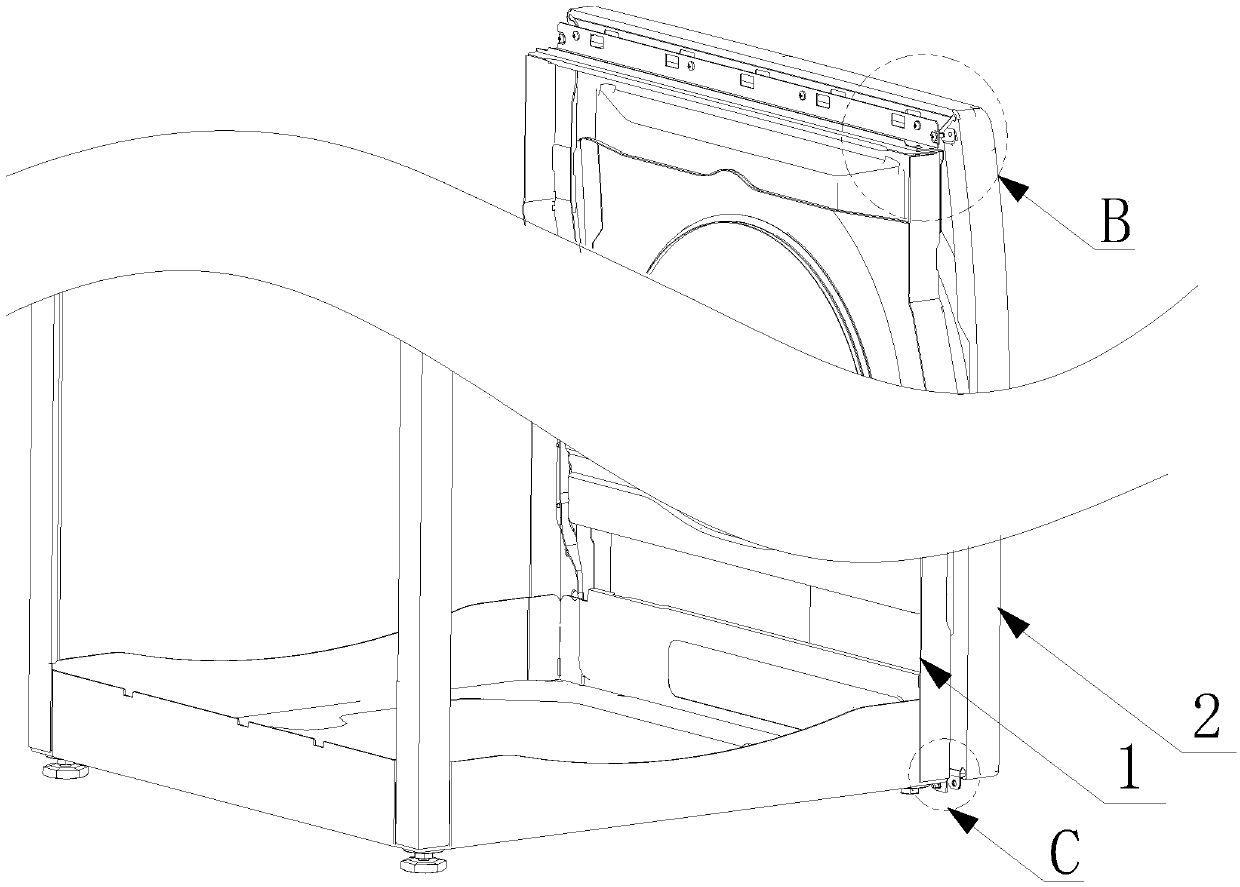

Embodiment 2

[0074] The difference between the second embodiment and the first embodiment is that the clothes treatment equipment does not have the aforementioned adapter 3, and after the upper edge of the front plate 2 of the clothes treatment equipment is bent downward, it is bent horizontally to the outside to form a skeleton 1 The fixed horizontal plane is connected, thereby forming the structural effect of connecting the front plate 2 and the adapter in the first embodiment as a whole, and the frame 1 also includes four vertically arranged reinforcing members 11, and two mating with the front plate 2 A cross beam 12 is connected to the top of the reinforcing member 11, and the horizontal plane is attached and fixed on the cross beam 12. In this solution, it is necessary to reserve material for bending out of the horizontal plane in the plate of the front plate 2. After the upper edge of the front plate 2 is bent down once, continue to the clothing treatment equipment on the formed bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com