Expressway guardrail

A guardrail and high-speed technology, applied to roads, road safety devices, roads, etc., can solve the problems of affecting the normal operation of the opposite vehicle, aggravating the severity of car accidents, and inserting the end into the car body, so as to reduce the risk of people being crushed. The effect of reducing vehicle speed and preventing forward rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

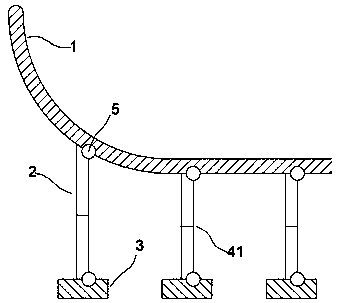

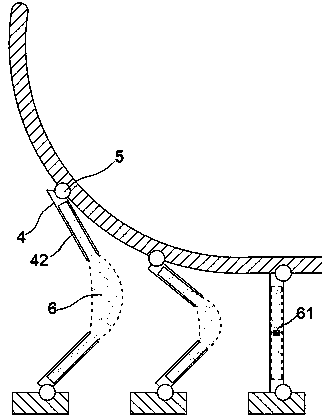

[0023] exist Figure 1 to Figure 4 In the shown embodiment, the high-speed guardrail includes a horizontal rail 1, a supporting column 2 and a fixing seat 3; the supporting columns 2 are equidistantly assembled and supported under the horizontal rail 1, and the fixing seats 3 Correspondingly installed on the lower end of the supporting column 2, the fixing seat 3 is fastened on the ground;

[0024] The end of the rail 1 is tilted upwards by 90°;

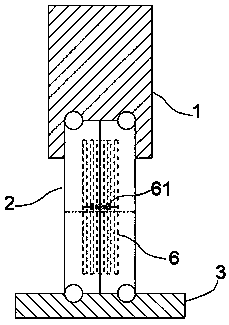

[0025] The support column 2 includes a pair of support rods 4 arranged in parallel, the upper ends of the support rods 4 are connected to the horizontal bar 1 through matching connecting balls and ball groove structures 5, and the lower ends of the support rods 4 are connected to the fixed seat 3 through Matching connecting balls and ball groove structures 5 are connected; the support rods 4 are made of permanent magnetic materials, and the paired two support rods 4 repel each other magnetically; Permanent magnet blocks with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com