Air compressor jigger convenient to operate

An air compressor technology with convenient operation, applied in electromechanical devices, mechanical equipment, control of mechanical energy, etc., can solve the problems of wasting labor costs, time-consuming and laborious, etc., and achieve the effect of improving work stability, high safety and reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

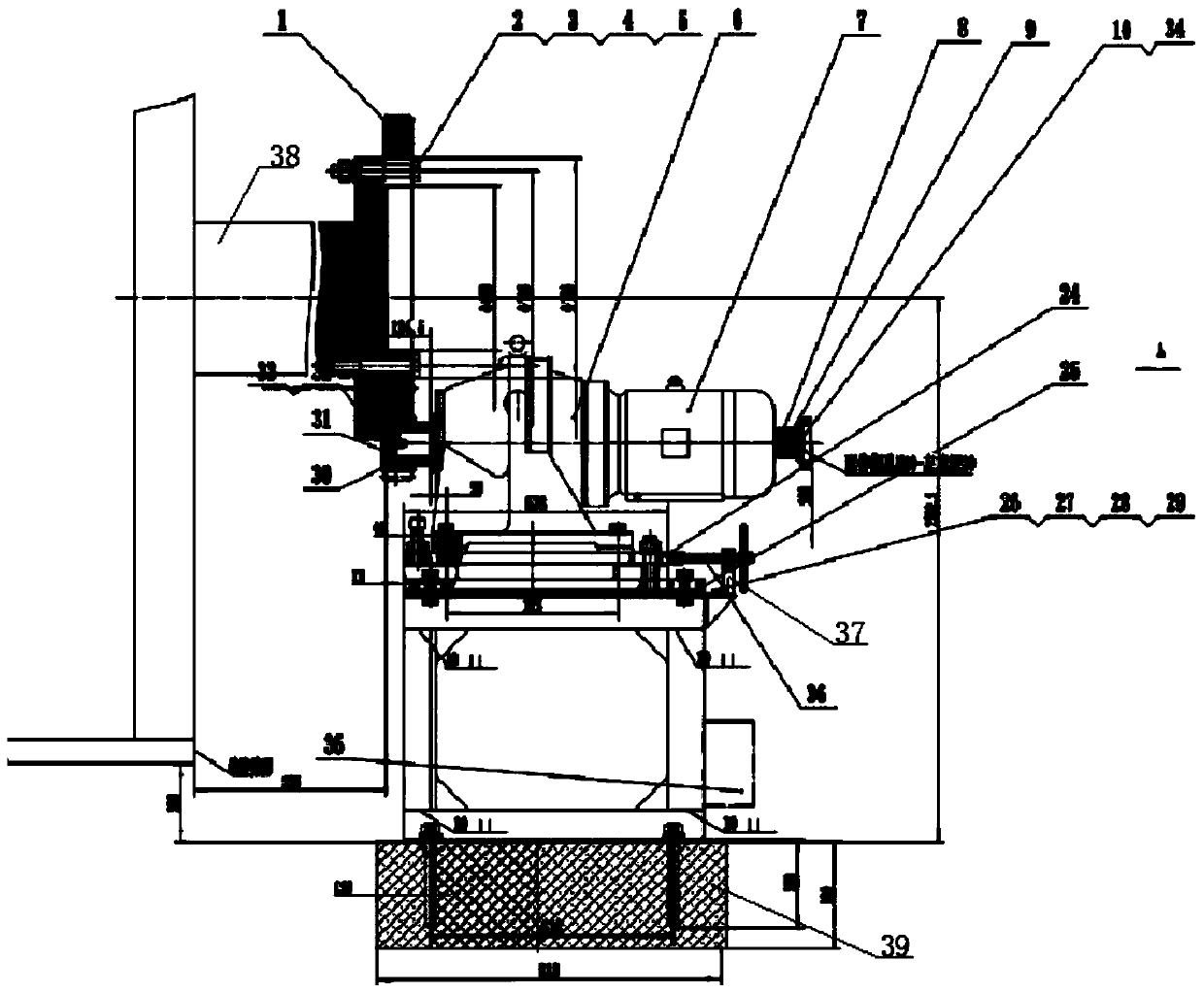

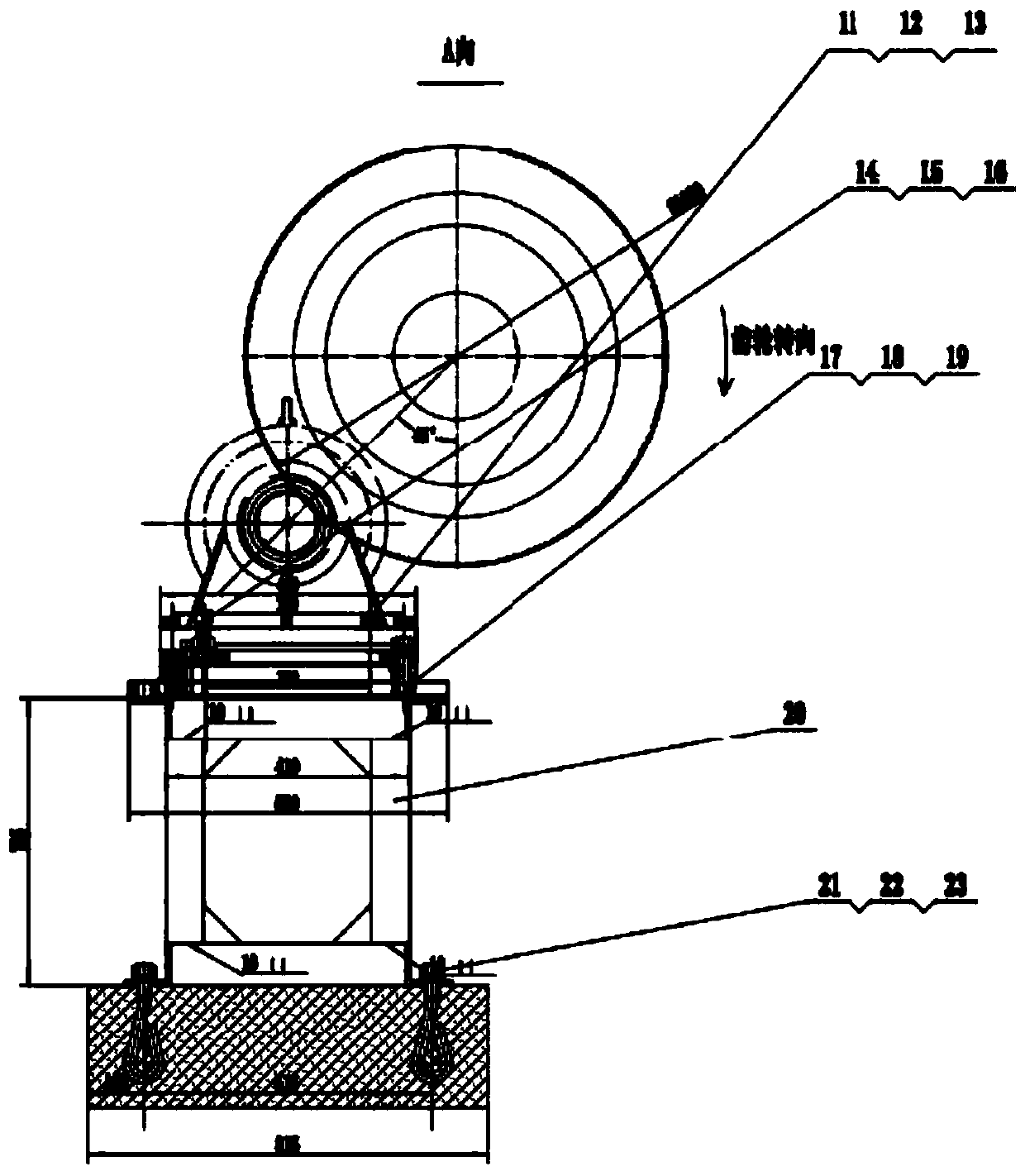

[0018] Such as Figure 1-2 As shown, a kind of easy-to-operate air compressor barring includes a small gear 30, a large ring gear 1, a reducer 6, a double shaft end motor 7, a bracket 20 and an electrical cabinet 35, and both sides of the top of the bracket 20 pass through The No. 1 bolt 26 is installed with the fixed plate II 25, the top of the No. 1 bolt 26 is threaded to the No. 1 nut 29, the top of the fixed plate II 25 is provided with a long groove, and the top of the long groove is installed with the fixed plate I 24 through a special stud 17, so The special stud bolt 17 is covered with a special washer 19 and a special spring washer 18, the top of the fixed plate I24 is installed with the reducer 6 through the second bolt 11, and the second bolt 11 is sleeved with the second spring washer 12 and the second washer 13. The double-shaft end motor 7 is installed on one side of the reducer 6 through fixing bolts, the rotating shaft on one side of the double-shaft end motor ...

Embodiment 2

[0024] Such as Figure 1-2 As shown, a kind of easy-to-operate air compressor barring includes a small gear 30, a large ring gear 1, a reducer 6, a double shaft end motor 7, a bracket 20 and an electrical cabinet 35, and both sides of the top of the bracket 20 pass through The No. 1 bolt 26 is installed with the fixed plate II 25, the top of the No. 1 bolt 26 is threaded to the No. 1 nut 29, the top of the fixed plate II 25 is provided with a long groove, and the top of the long groove is installed with the fixed plate I 24 through a special stud 17, so The speed reducer 6 is installed on the top of the fixing plate I24 through the No. 2 bolt 11, and the No. 2 spring washer 12 and the No. 2 washer 13 are sleeved on the No. 2 bolt 11. The side of the speed reducer 6 is installed with the double shaft end motor 7 through the fixing bolts. , the rotating shaft on one side of the double-shaft end motor 7 is connected to the input shaft of the reducer 6, and the rotating shaft on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com