Escalator with offload guide rail abrasion detection function

A technology for unloading guide rails and escalators, which is applied in escalators, transportation and packaging, etc., and can solve the problems of unloading guide rails that do not have the ability to detect their wear, step chain rollers and step chain roller guide rail wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

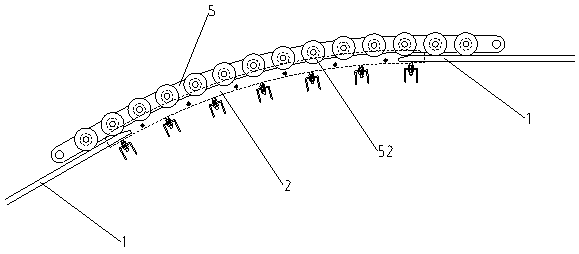

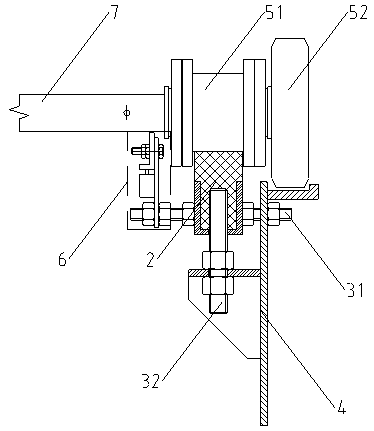

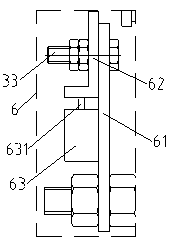

[0030] see Figure 1-Figure 4 , an escalator with an unloading guide rail wear detection function, comprising two parallel running step chain groups, the two step chain groups are connected by a step shaft 7 . The step chain set includes a step chain roller guide rail 1 and an unloading guide rail 2 . The unloading guide rail 2 is located at the upper transition arc section of the step chain roller guide rail 1 . The unloading guide rail 2 is fixed on the guide rail bracket 4 of the escalator through the first connecting bolt 31, the first connecting nut and the second connecting bolt 32, and the second connecting nut. When the step chain 5 runs on the upper transition section of the escalator, the step chain roller 51 can act on the unloading guide rail 2 and make the step chain roller 52 suspended. During specific implementation, the step chain roller 52 can be located inside the step chain roller 51 or outside the step chain roller 51, that is, the positions of the step c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com