Pile hammer assembly and pile driver with pile hammer assembly

A component and pile hammer technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of accurate alignment, difficult operation, damage and other problems, and achieve reliable alignment, convenient alignment and clamping, strong The effect of freedom of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

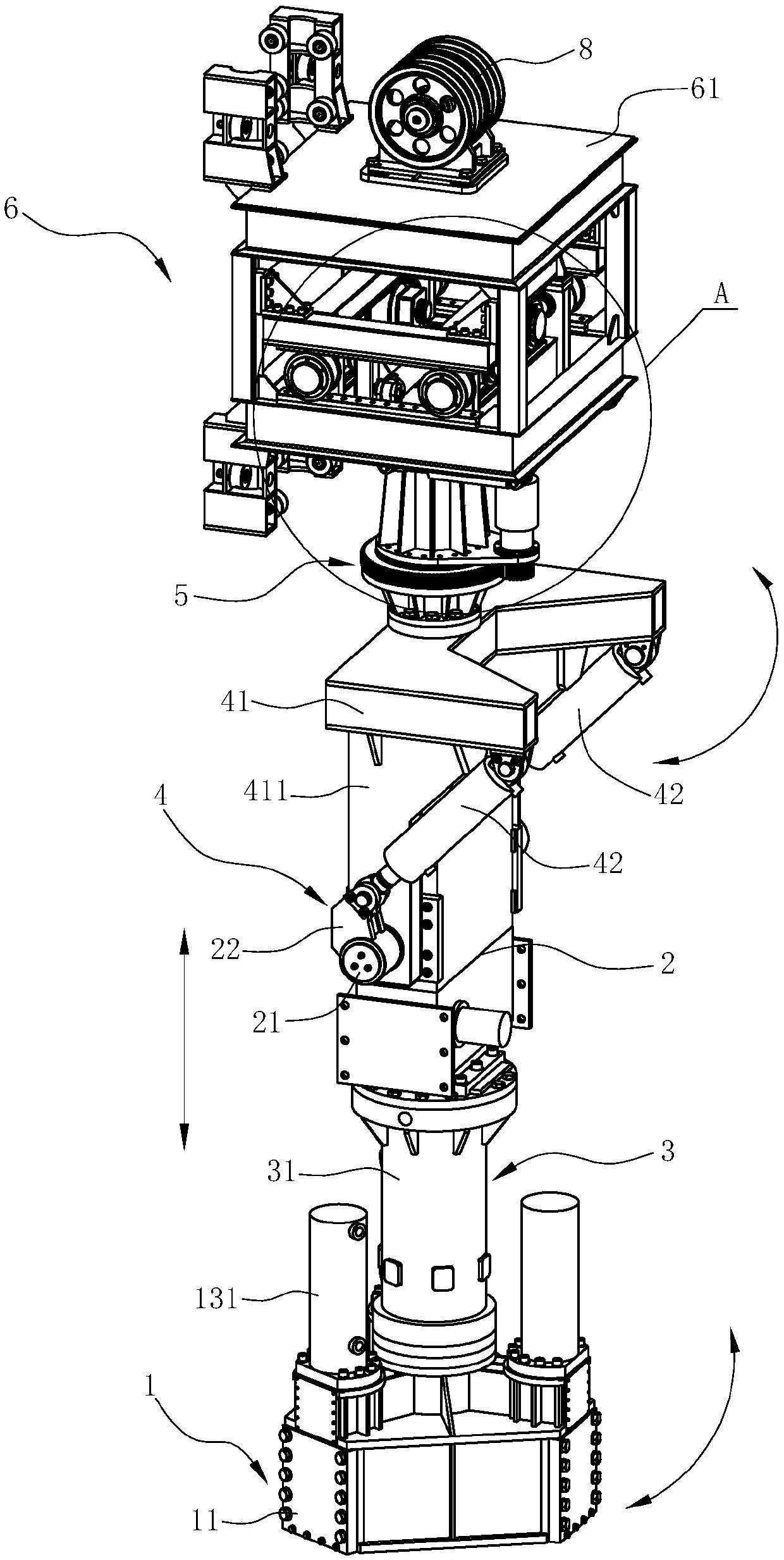

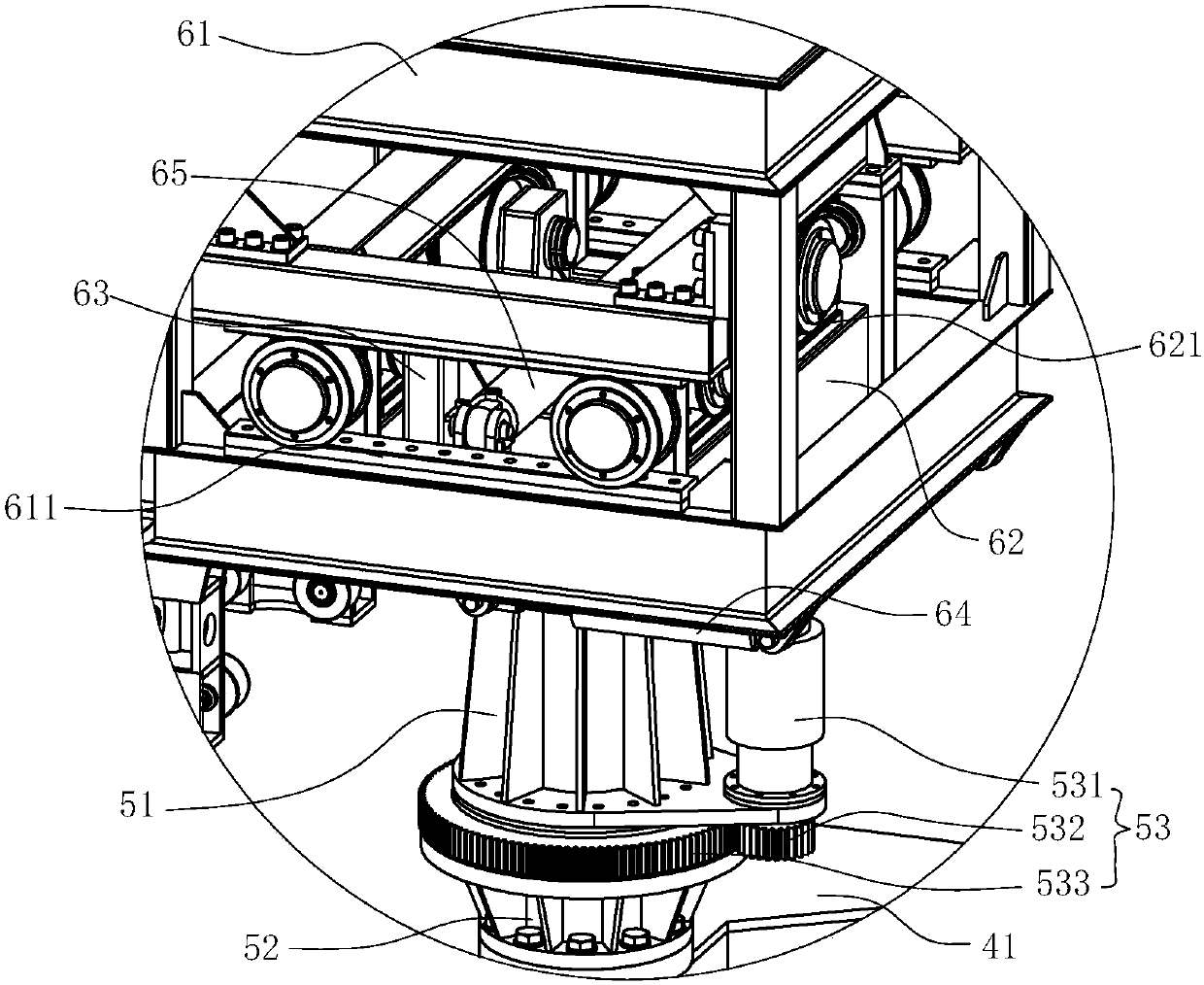

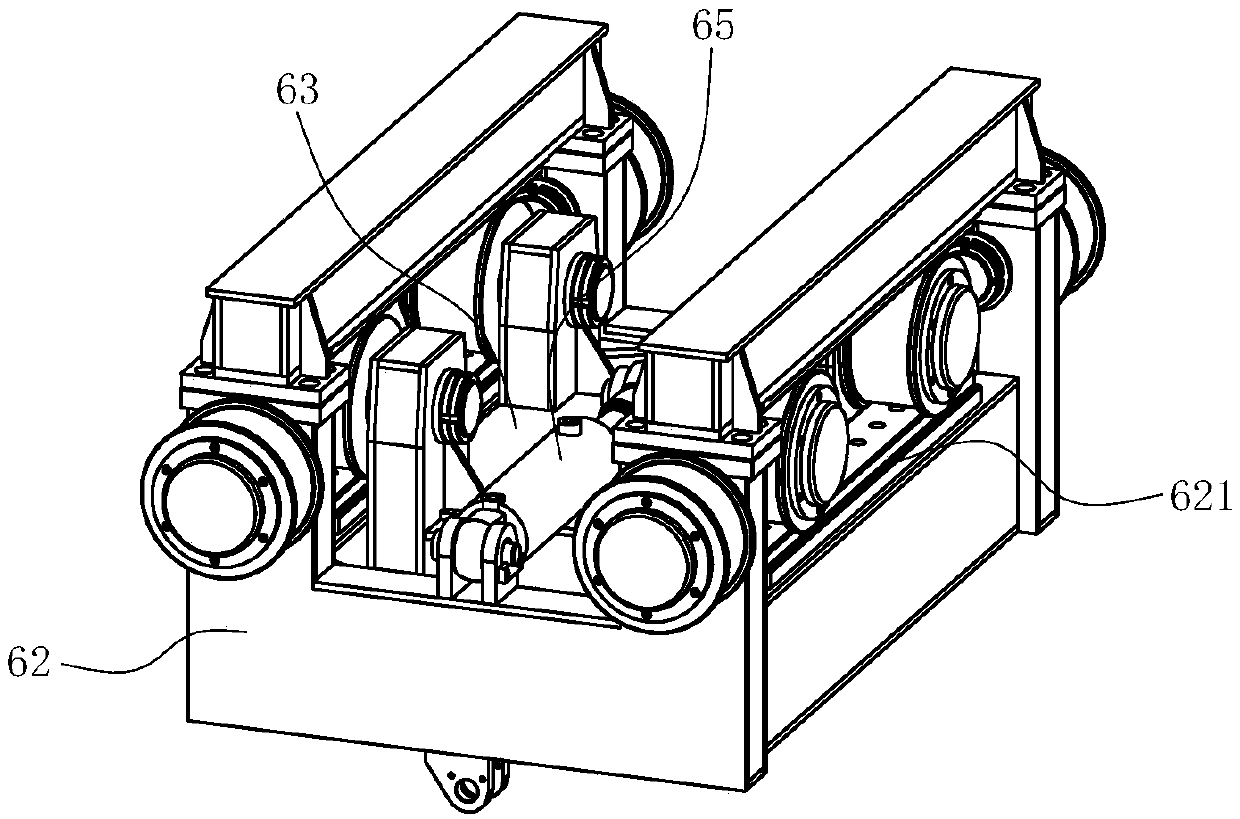

[0045] Such as Figure 1-12 Shown is a preferred embodiment of the pile hammer assembly in the present invention.

[0046] A pile hammer assembly includes a pile clamp 1 for clamping prefabricated piles, and a pile sinking device 2 directly or indirectly acting on the pile clamp 1 .

[0047] Such as Figures 9 to 12 As shown, the pile clamp 1 includes a housing 11 with a pile clamping hole 111 with an opening facing downwards. The housing 11 is provided with a plurality of clamping blocks 12 that extend into the pile clamping hole 111 and can slide radially. There are three clamping blocks 12, and the three clamping blocks 12 are evenly spaced along the inner peripheral surface of the pile clamping hole 111. Each clamping block 12 is driven by the fourth driving device 13 to move reciprocatingly in the radial direction, and the radial recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com