Hydrogen sulfide and carbonyl sulfide resource recycling method based on molten salt

A technology of hydrogen sulfide and carbonyl sulfide, applied in chemical instruments and methods, magnesium/calcium/strontium/barium sulfide/polysulfide, separation methods, etc., can solve the problem of not considering the stability of molten salt, unrecoverable sulfur, etc. problems, to achieve the effect of ensuring long-term stable operation, realizing resource recycling, and ensuring utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of functional molten salt: mix lithium carbonate, sodium carbonate, and potassium carbonate according to the mass ratio of 32.1:33.4:34.5, weigh 50 g of the mixed carbonate, add 5 g of calcium carbonate to the mixed carbonate, and perform mechanical grinding for 1 hours, followed by heating and melting to form a liquid functional molten salt;

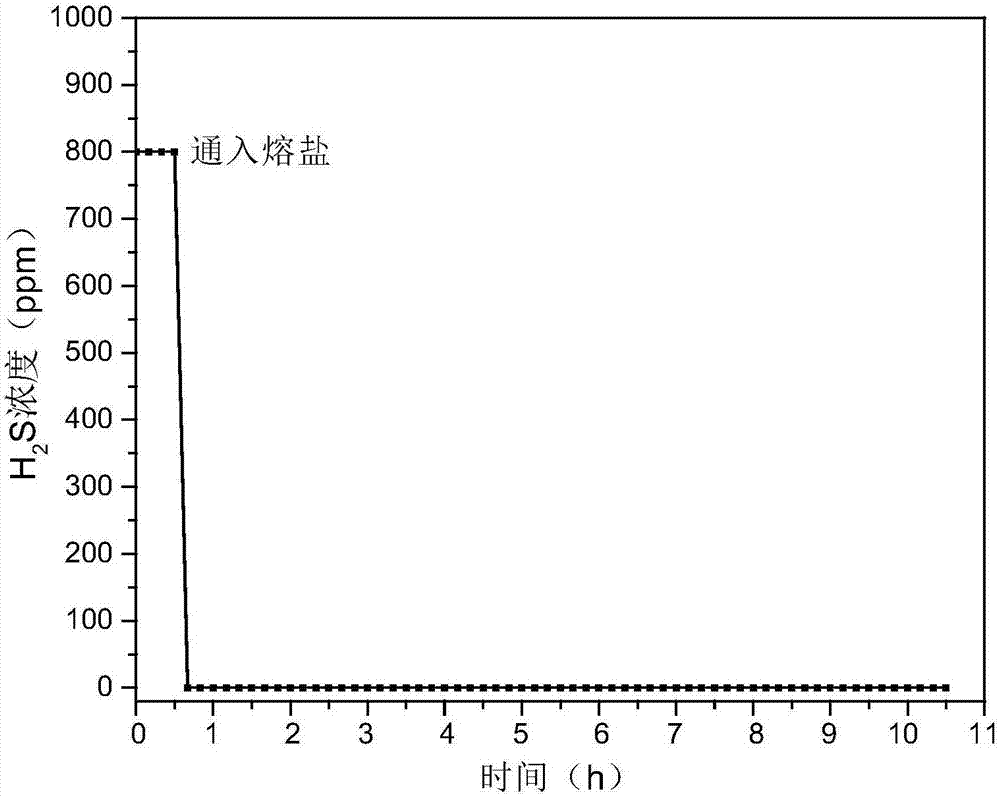

[0028] (2) Hydrogen sulfide adsorption and enrichment: heat the functional molten salt to 500°C, add 2% carbon powder to the molten salt, and then pass hydrogen sulfide with a concentration of 800ppm into the molten salt, and the adsorption reaction is maintained for 10 hours. The concentration of hydrogen sulfide in the exhaust gas is figure 1 As shown, it can be seen that the removal rate of molten salt to hydrogen sulfide reaches 100%;

[0029] (3) Sulfide recovery: suspend the introduction of gas containing hydrogen sulfide, add 3g of calcium carbonate to the molten salt system after the reaction, stir for ha...

Embodiment 2

[0033] (1) Preparation of functional molten salt: mix lithium carbonate, sodium carbonate, and potassium carbonate according to the mass ratio of 32.1:33.4:34.5, weigh 50g of the carbonate mixture, add 12.5g of barium carbonate to the mixed carbonate, and perform mechanical grinding 1 hour, followed by heating and melting to form a liquid functional molten salt;

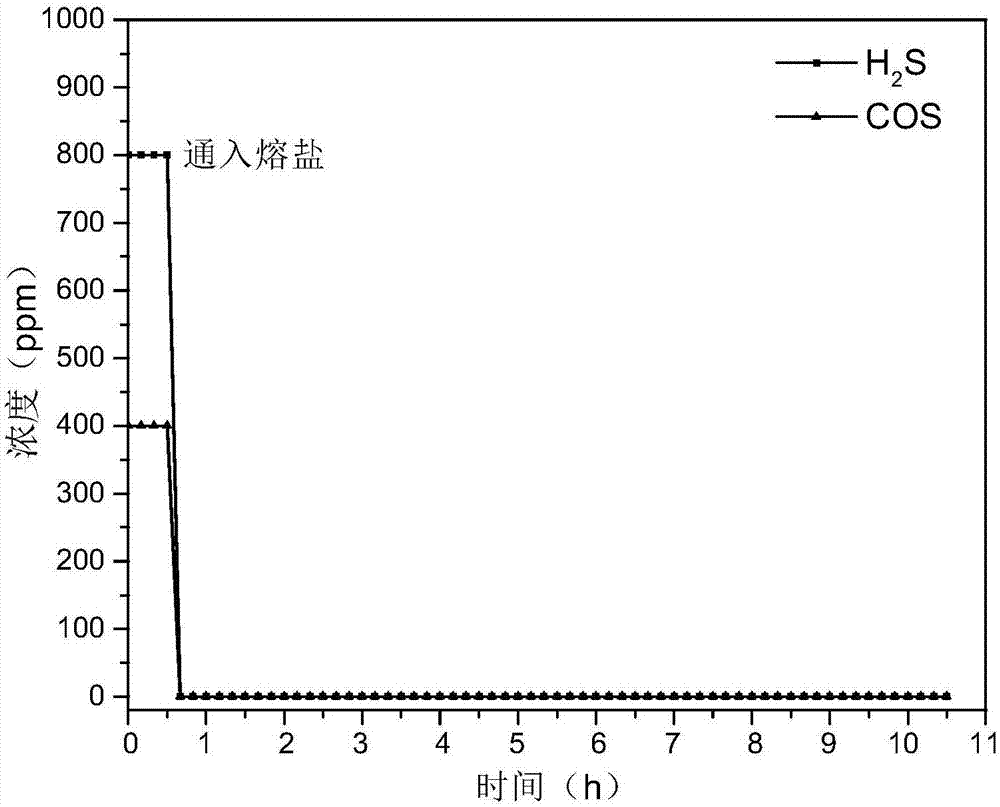

[0034] (2) Adsorption and enrichment of hydrogen sulfide and carbonyl sulfide: heat the functional molten salt to 750°C, add 5% carbon powder to the molten salt, then pass hydrogen sulfide with a concentration of 800ppm and carbonyl sulfide with a concentration of 400ppm into the molten salt, The adsorption reaction was maintained for 10 hours, and the concentration of hydrogen sulfide and carbonyl sulfide in the tail gas was detected as figure 2 As shown, it can be seen that the removal rate of molten salt to hydrogen sulfide and carbonyl sulfide reaches 100%;

Embodiment 3

[0039] (1) Preparation of functional molten salt: mix lithium chloride, sodium chloride, and potassium chloride according to the mass ratio of 32.8:33.8:33.4, weigh 50 g of the mixed chloride salt, add 10 g of barium chloride to the mixed chloride salt, and Perform mechanical grinding for 1 hour, then heat and melt to form liquid functional molten salt;

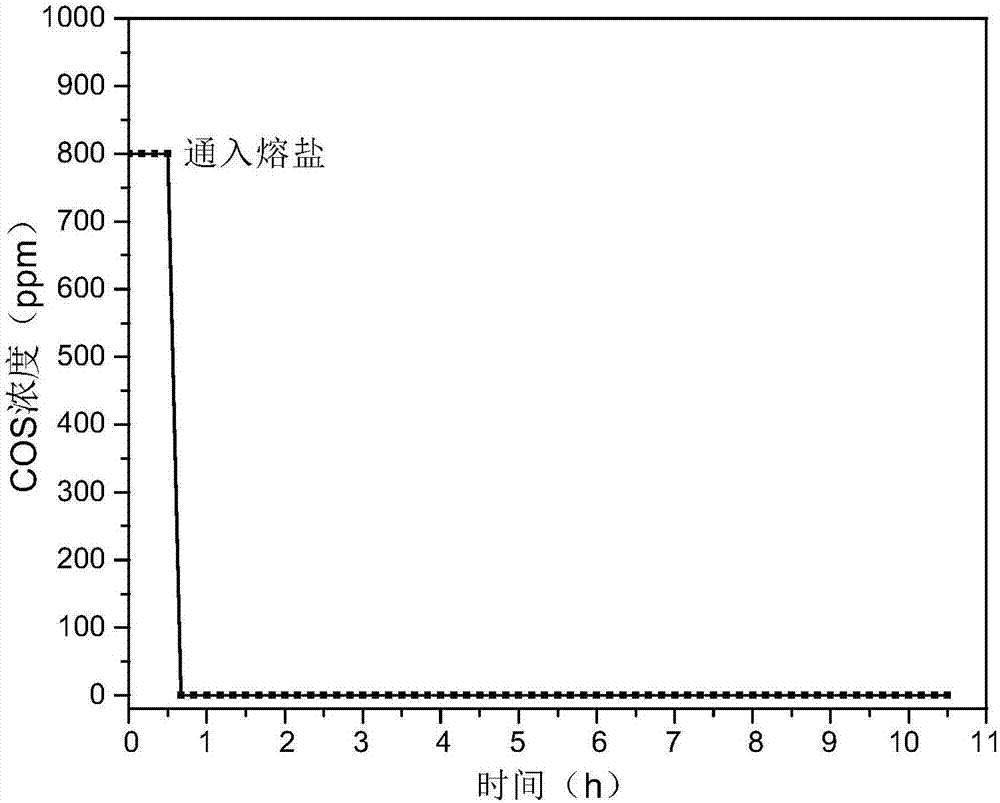

[0040] (2) Carbonyl sulfide adsorption and enrichment: heat the functional molten salt to 600°C, add 3% carbon powder to the molten salt, then pass carbonyl sulfide with a concentration of 800ppm into the molten salt, and maintain the adsorption reaction for 10 hours. The concentration of carbonyl sulfide in the exhaust gas is as image 3 As shown, it can be seen that the removal rate of molten salt to carbonyl sulfide reaches 100%;

[0041] (3) Sulfide recovery: suspend the introduction of gas containing carbonyl sulfide, add 3g of barium chloride to the molten salt system after the reaction, stir for half an hour and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com