A pre-embedded device for building pipelines and its construction method

A technology for pre-embedding devices and pipes, which is applied in the fields of buildings, building structures, and on-site preparation of building components, can solve the problems of inability to adapt to different concrete building thicknesses, difficult to take out, and inconvenient adjustment of the height of pipeline pre-embedded equipment. To achieve the effect of convenient filling work, convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

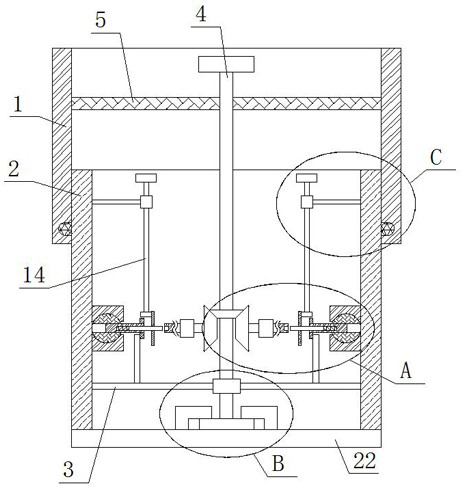

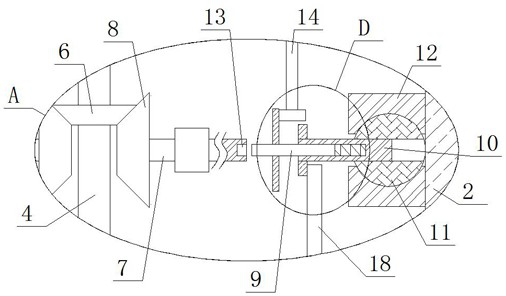

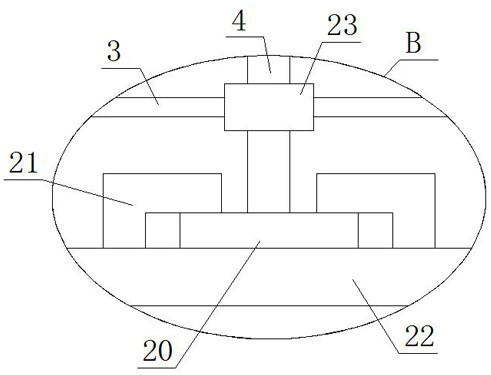

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0030] refer to Figure 1-5 , a pre-embedded device for building pipelines, comprising an outer tube 1 and an inner tube 2 movably sleeved on the inner side of the outer tube 1, brackets 3 are welded on the inner walls of both sides of the inner tube 2, and one end of the two brackets 3 close to each other is rotated and installed There is the same first screw rod 4, the outer threaded sleeve of the first screw rod 4 is provided with a cross bar 5, the two ends of the cross bar 5 are welded on the outer tube 1, and the inner tube 2 is equipped with two first shafts 7 for rotation, the screw rod The outer side of 4 is welded with a first helical gear 6, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com