Reversing single open flushing solenoid valve

A solenoid valve and flushing technology, which is applied to valve details, valve devices, multi-way valves, etc., can solve problems such as poor flushing effect and complex valve body structure, and reduce hidden dangers of product sealing performance, cost reduction, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

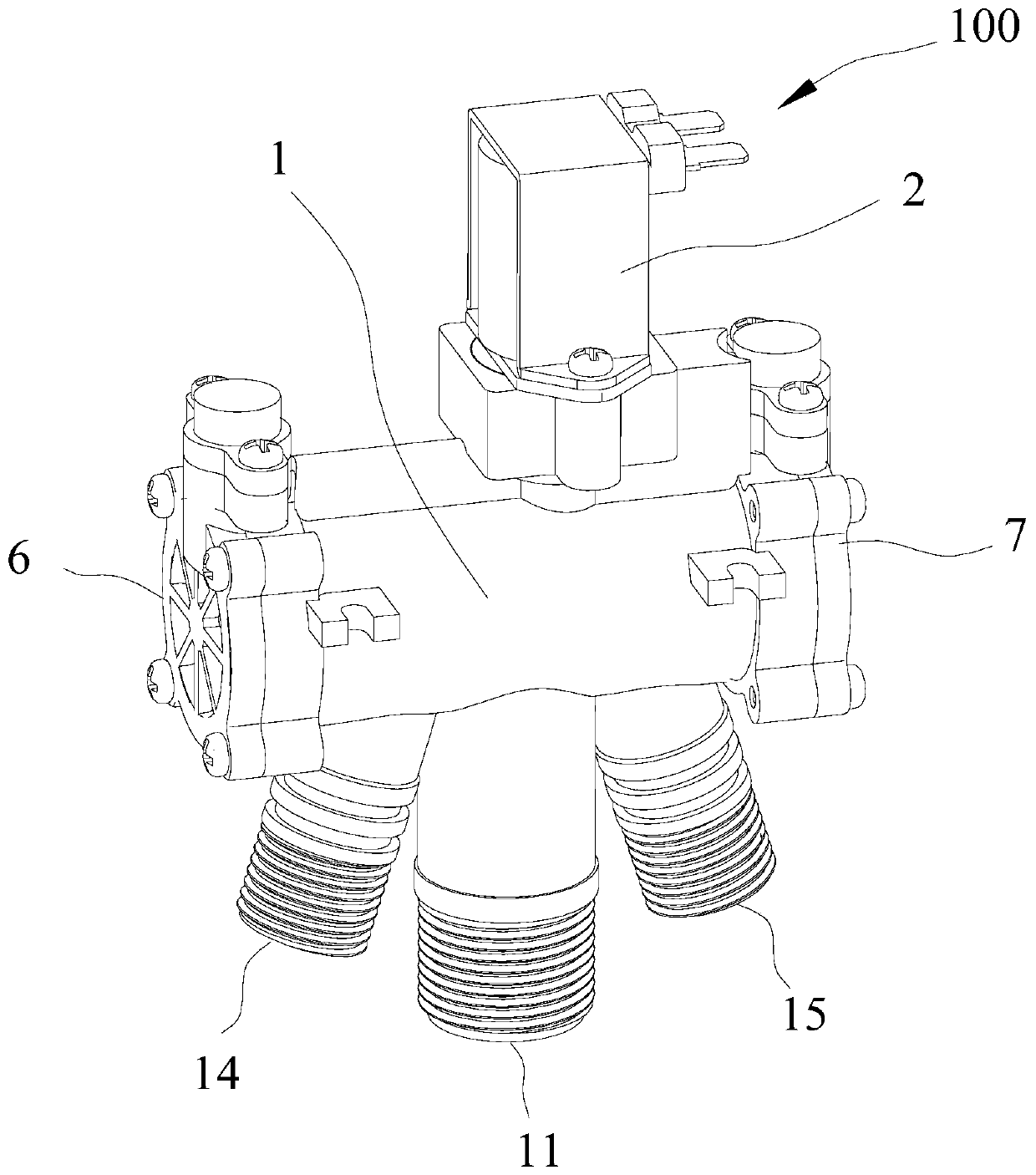

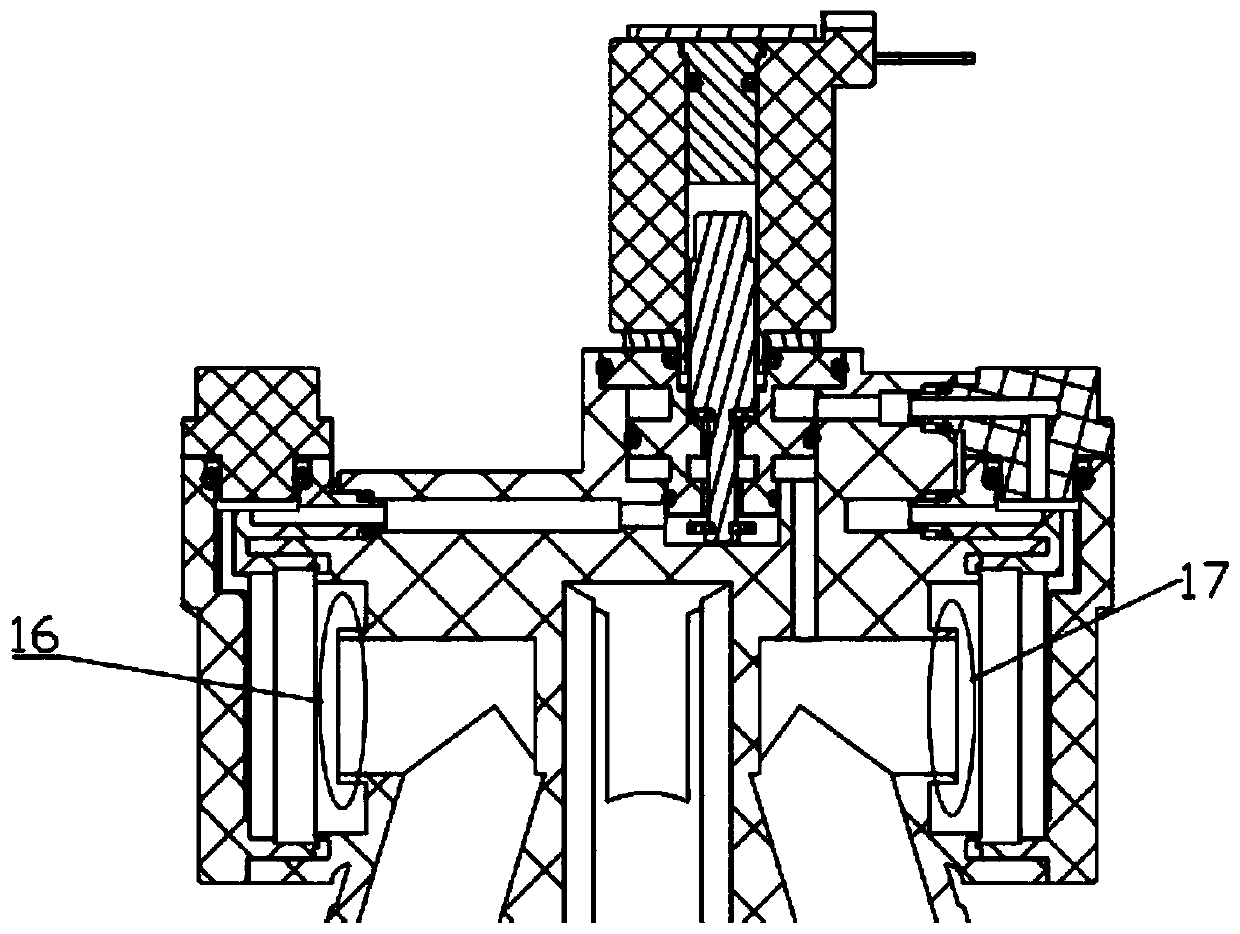

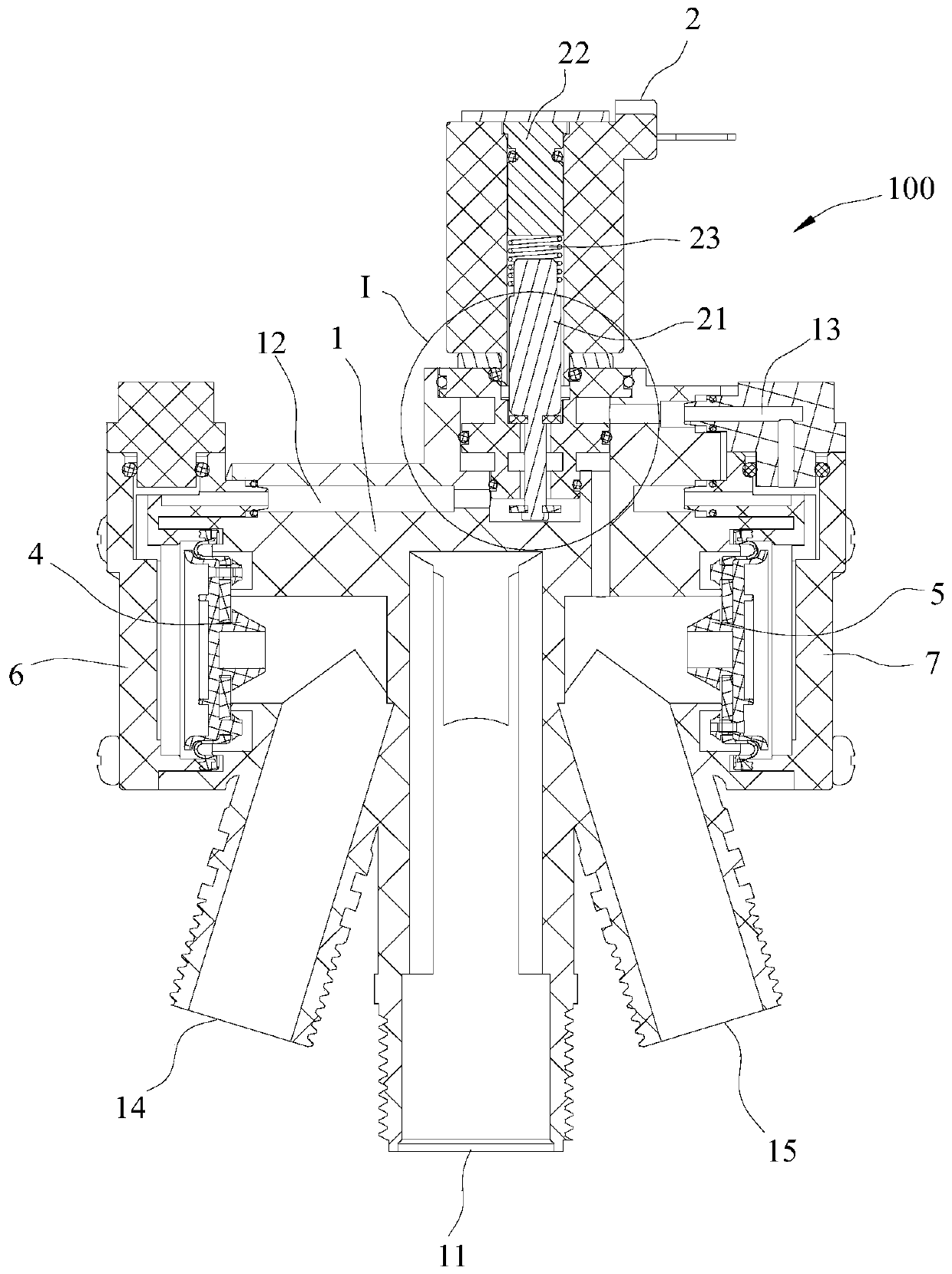

[0079] figure 1 Schematic diagram of the structure of the solenoid valve provided in the embodiment of the present application; figure 2 The main sectional view of the solenoid valve provided for the embodiment of the present application (without disc assembly); image 3 The main sectional view of the solenoid valve provided for the embodiment of the present application when it is not energized; Figure 4 for image 3 Enlarged view of I; Figure 5 The main cross-sectional view of the solenoid valve provided for the embodiment of the present application when it is energized; Figure 6 for Figure 5 Enlarged view of J; Figure 7 A schematic diagram of the water flow of the solenoid valve provided in the embodiment of the present application when it is not powered on; Figure 8 A schematic diagram of water flow when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com