Fault grading-based fault warning method and device and equipment

A fault warning and equipment technology, applied to alarms, instruments, etc., can solve problems such as untimely reminders, achieve the effect of preventing large losses and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

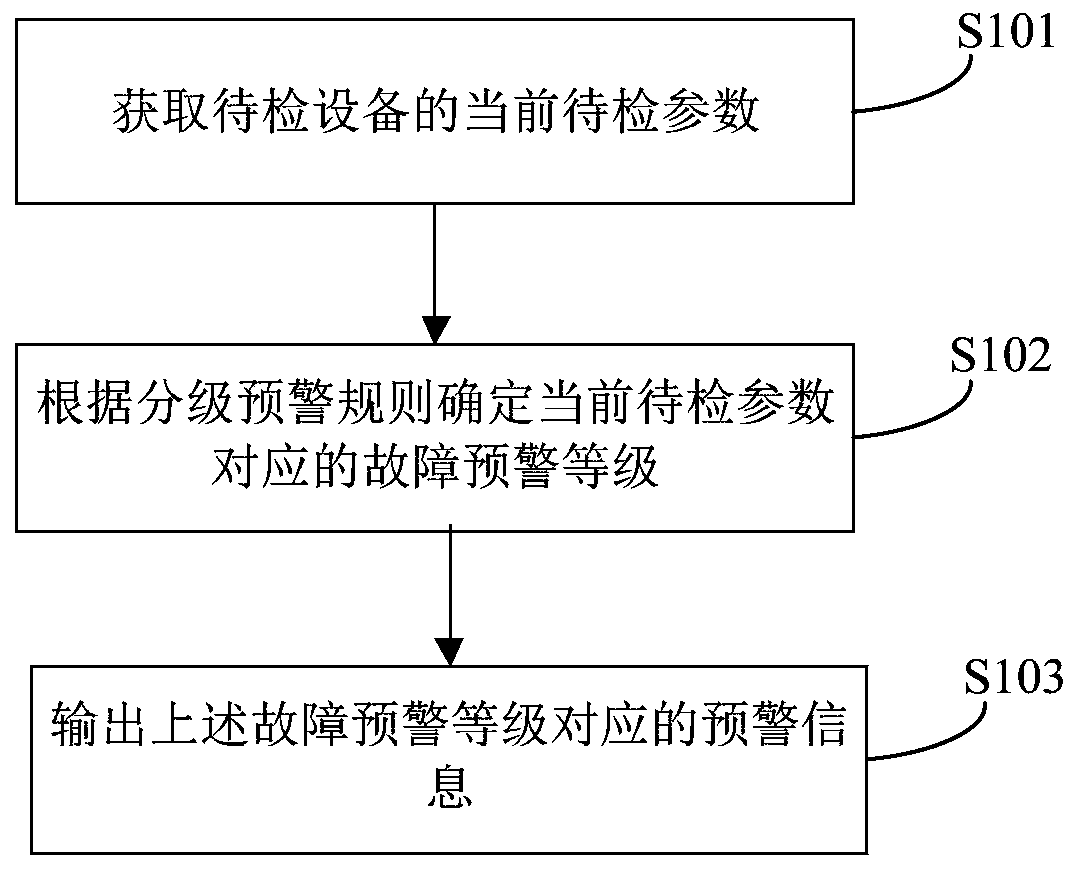

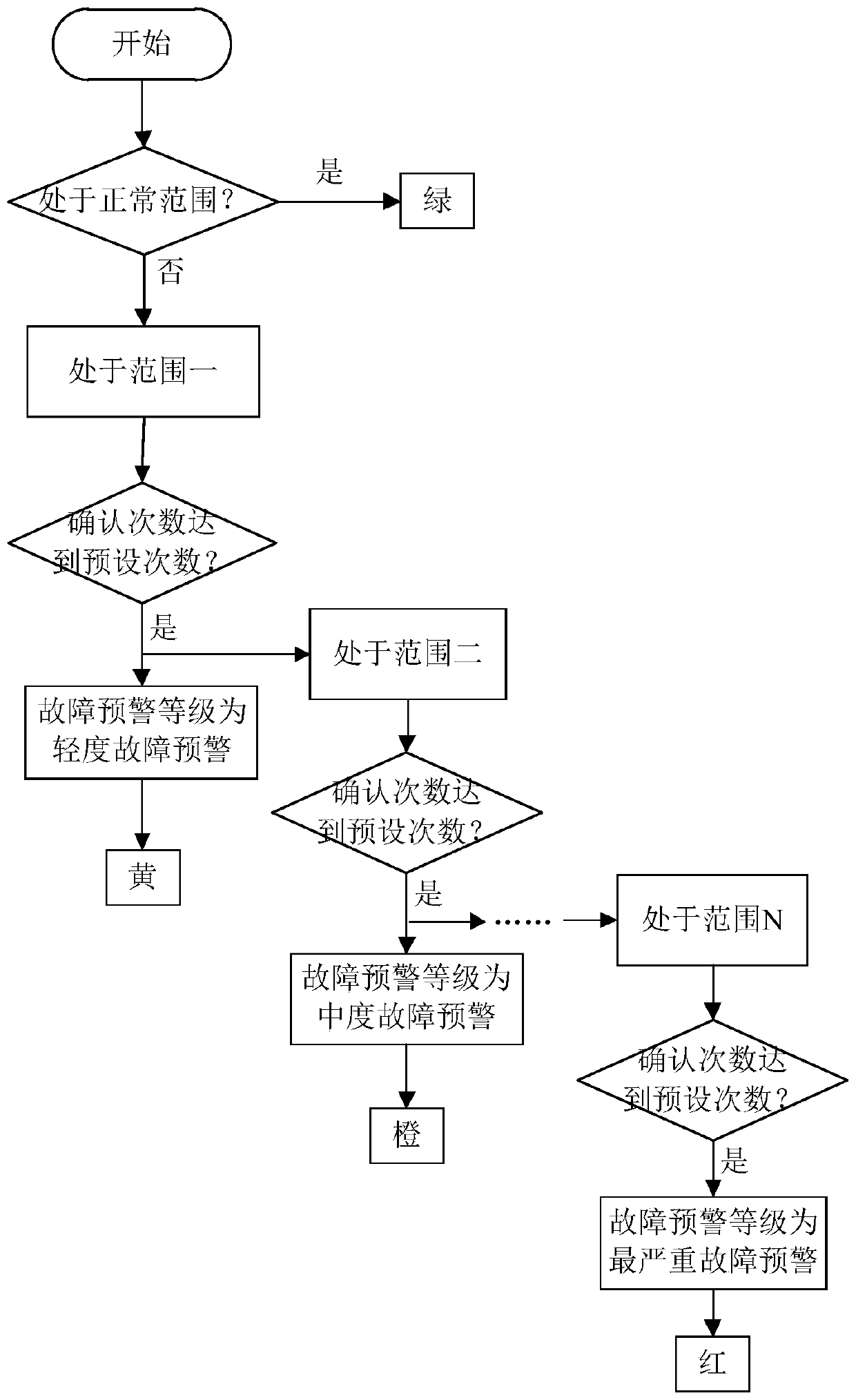

[0056] This embodiment provides a fault early warning method based on fault classification, which can be used for fault early warning of equipment or systems, so that users can predict fault situations in advance and take timely measures. figure 1 It is a flow chart of the fault early warning method based on fault classification provided by Embodiment 1 of the present invention, as shown in figure 1 As shown, the method includes the following steps:

[0057] S101. Obtain the current parameters of the device to be checked.

[0058]For different equipment to be inspected, corresponding parameters to be inspected can be set in advance according to the characteristics of the equipment for fault warning. The parameters to be checked are key parameters that can reflect whether the equipment is running normally. A device to be checked can set one or more parameters to be checked. If a parameter to be checked is set, the fault warning level corresponding to the parameter to be chec...

Embodiment 2

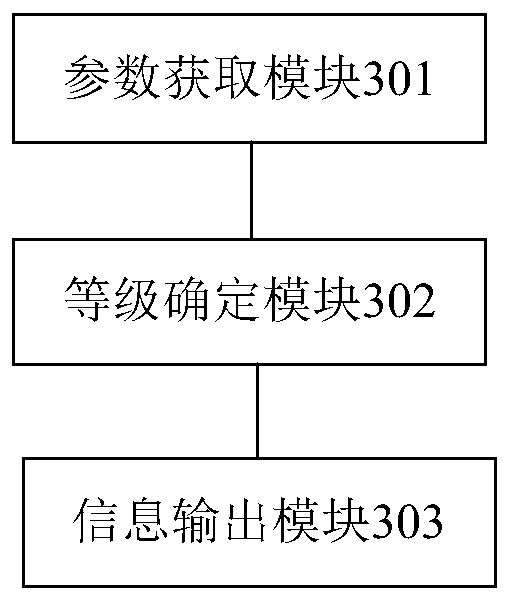

[0078] This embodiment provides a fault early warning device based on fault classification, which can be used to implement the fault early warning method based on fault classification described in the above embodiments. The device can be realized by software and / or hardware, and the device can be integrated in a terminal with computing and processing functions, such as a PC. The PC is used as the upper computer, and the device to be checked is used as the lower computer.

[0079] image 3 It is a structural block diagram of a fault early warning device based on fault classification provided by Embodiment 2 of the present invention, as image 3 As shown, the device includes:

[0080] A parameter acquisition module 301, configured to acquire the current parameters to be checked of the device to be checked;

[0081] The level determination module 302 is used to determine the fault early warning level corresponding to the current parameter to be checked according to the hierarch...

Embodiment 3

[0098] This embodiment provides a device, including the fault early warning device based on fault classification described in the above embodiments. For technical details not exhaustively described in this embodiment, refer to the device provided in any embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com