Device and method for cutting a continuous strip into tire components

A cutting device and strip technology, applied in the field of tire components, can solve the problems of inaccessible space, safe access by operators, large space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

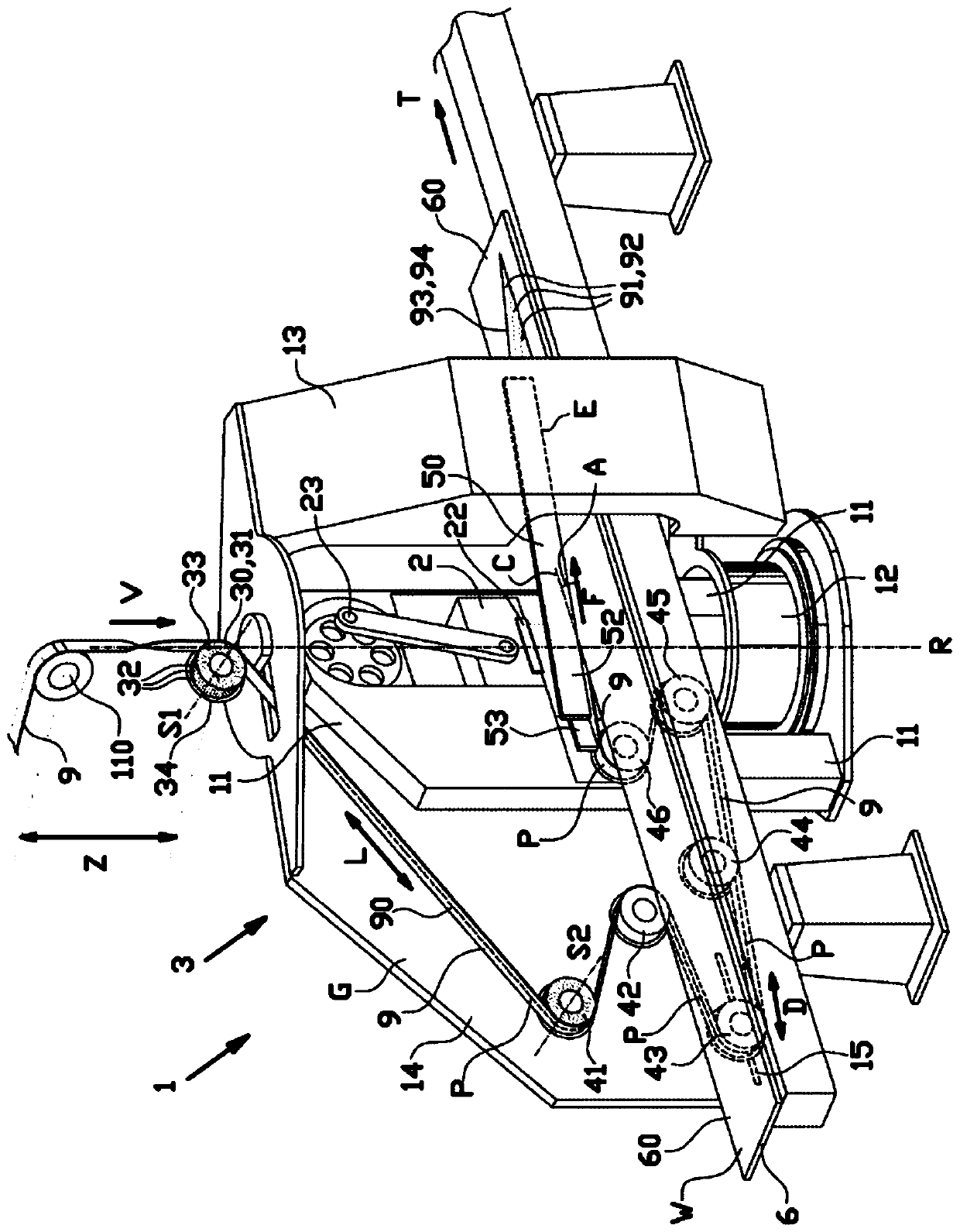

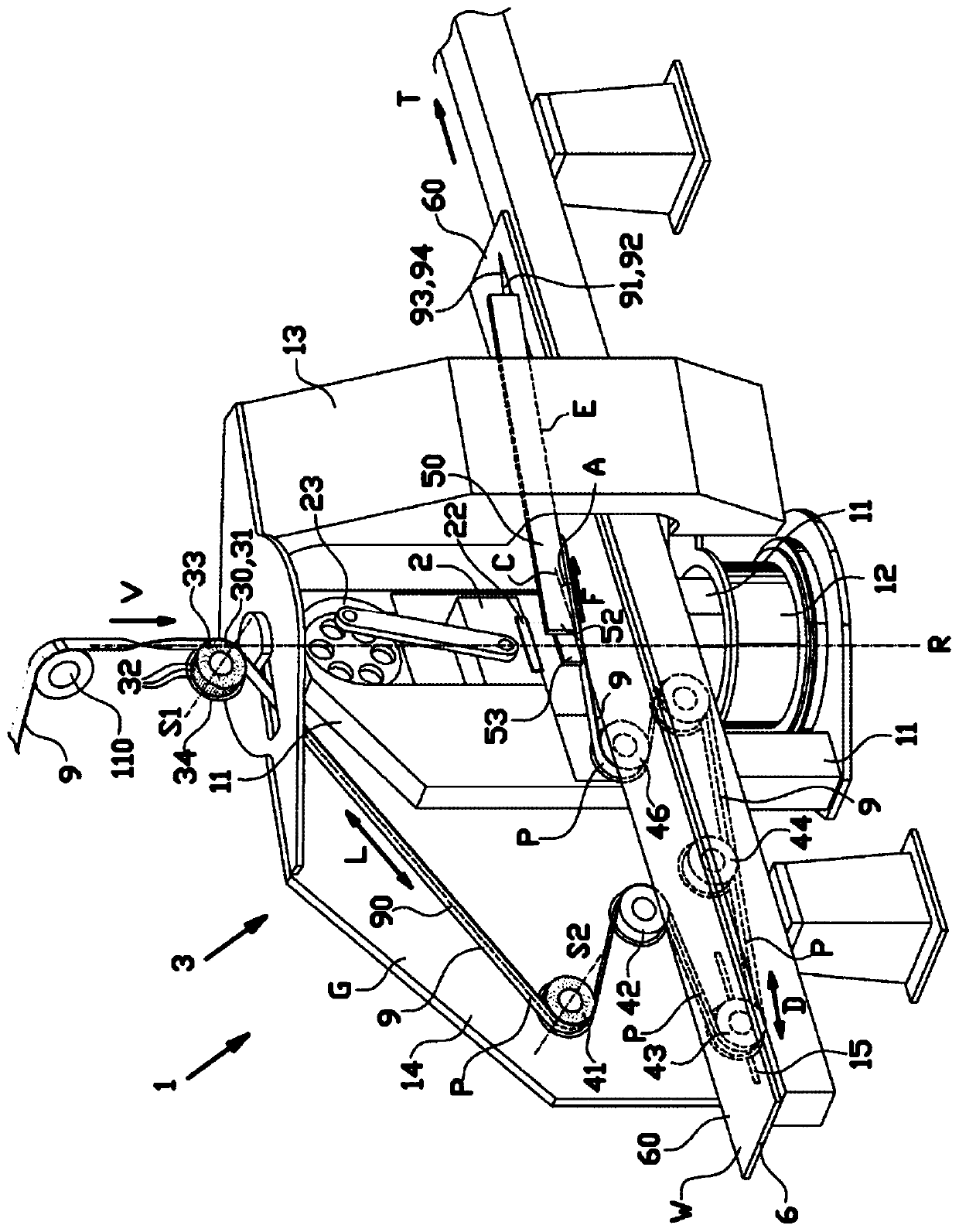

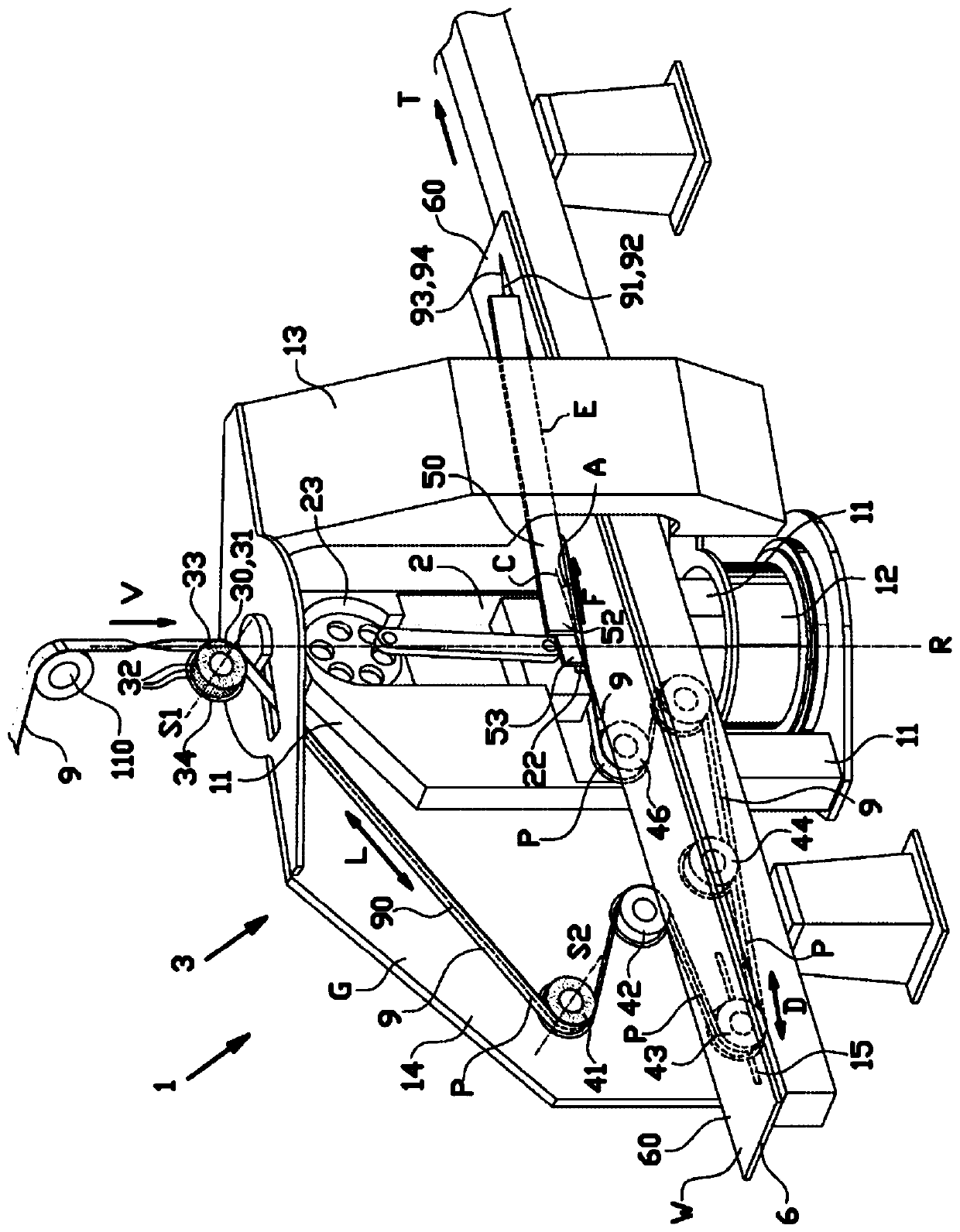

[0050] Figure 1-9 A cutting device 1 for cutting a continuous strip 9 into one or more tire components is shown according to a first embodiment of the invention. Figure 5 and Figure 6 Tire components 91 , 92 cut by the cutting device 1 at different cutting angles A are shown. Said cut tire parts 91 , 92 are preferably used in a manner known per se for building breakers 93 , 94 . The continuous strip 9 has a substantially planar main surface 90 extending in a longitudinal direction L of said continuous strip 9 and a plurality of reinforcing cords extending in the same longitudinal direction L.

[0051] Such as figure 1 , 2 As shown in and 3, the cutting device 1 comprises a knife 2 for cutting the continuous strip 9 into cut tire parts 91, 92 along a cutting line C in the working plane W, for cutting the cutting line C at a cutting angle A Feed assembly 3 that feeds the continuous strip 9 to the cutter 2 in a feed direction F of , and an output member 6 for outputting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com