Constant temperature fermentation process for fermented soy bean production

A technology of constant temperature fermentation and fermented soybeans, which is applied in food heat treatment, food science, etc., can solve the problems of difficult acidity control, low acidity adjustment efficiency, and difficult sampling in fermentation tanks, and achieve stability, temperature control, and quality improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

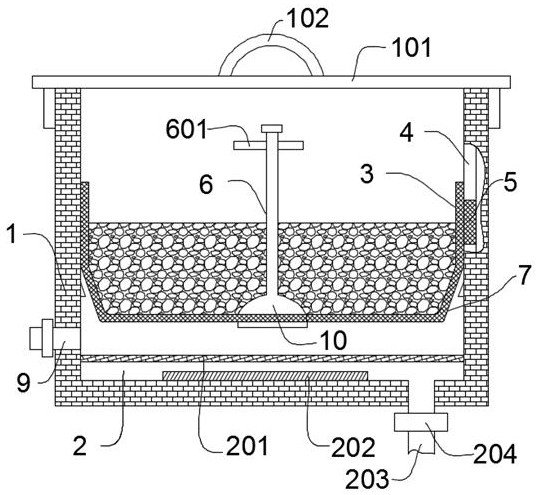

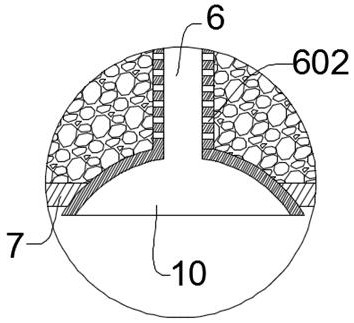

[0026] refer to figure 1 As shown, one embodiment of the present invention is a constant temperature fermentation process for fermented soya bean production, comprising the following steps: configuring the fermentation environment, adjusting the internal temperature of the tank 1 of the constant temperature fermentation device, and injecting the configuration liquid into the tank 1 , through the heating part 2 inside the tank body 1 to control the temperature of the configuration liquid, so that the configuration liquid volatilizes in the tank body; as we all know, the optimum growth temperature of Aspergillus oryzae is 30 to 35 degrees Celsius, and the optimum pH value is 6. Therefore, here Basically, the internal temperature of the tank for the fermentation process is 30 to 35 degrees Celsius, and the pre-environmental conditions.

[0027] In order to ferment fermented soybeans effectively in this environment, pretreatment is required. The usual pretreatment stage is soaking...

Embodiment 2

[0034] Based on the above-mentioned embodiment, another embodiment of the present invention is that the above-mentioned fermentation environment configuration, the temperature control of the above-mentioned configuration liquid is cut off by the cooling plate 201, and two independent chambers are formed in the tank body 1, and the upper part of the cooling plate 201 is stored The heat conducting medium is stored in the lower part of the cooling plate 201 for disposing the liquid, and the heating element 2 is used to heat up the heat conducting medium, and the thermal energy of the heat conducting medium is transferred to the disposing liquid by the heat dissipating plate 201, so as to control the temperature of the disposing liquid.

[0035] Specifically, the heating part 2 includes a heat dissipation plate 201 and a heating element 202. The heat dissipation plate 201 is sealed and arranged at the bottom of the tank body 1. The heating element 202 is installed at the bottom of t...

Embodiment 3

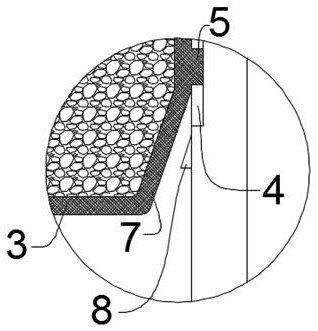

[0038] Based on the above-mentioned embodiment, another embodiment of the present invention is that the side wall of the above-mentioned hanging box is air-permeable, and the side wall of the hanging box 3 is placed at an inclined angle, and is limited on the inner wall of the tank body 1 to increase the hanging. The contact area between box 1 and tempeh.

[0039] Specifically, the hanging box 3 is made of stainless steel, and the wall of the hanging box 3 is a mesh structure, so that the hanging box 3 is evenly covered with permeable holes, and the upper end of the hanging box 3 is open, so that the fermented soybean meal is placed in the hanging box 3. placed in the middle; the two ends of the hanging box 3 are welded with stainless steel protrusions 5, and its chute 4 is opened on the side wall of the tank body 1, and the chute 4 is vertically arranged, and the upper end of the chute 4 extends to the tank body 1 At the upper end, the protrusion 5 is inserted into the chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com