Automatic paper lace printing equipment

An automatic printing and lace technology, applied in the directions of printing, transfer materials, power transmission devices, etc., can solve the problems of low paper printing efficiency, complex printing equipment structure, poor printing effect, etc. Strong performance and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

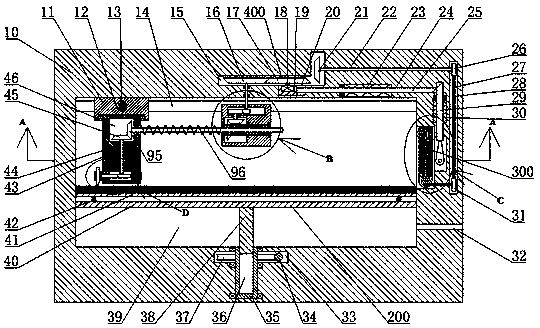

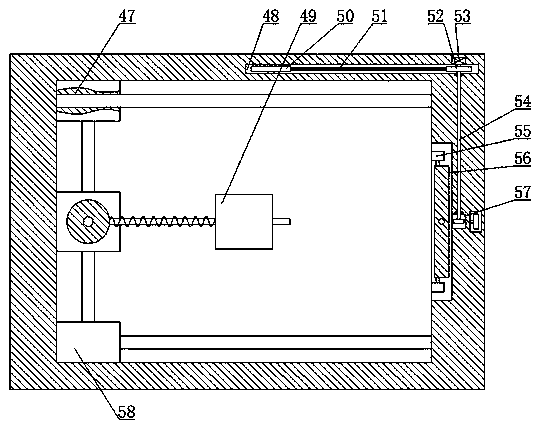

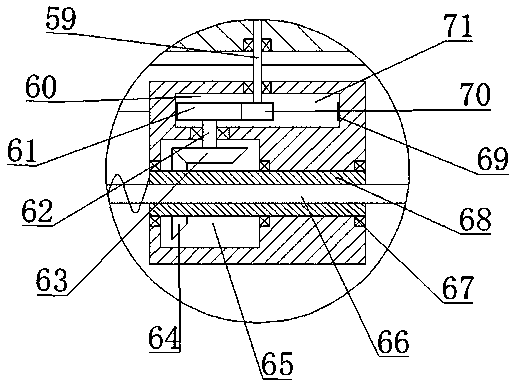

[0021] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0022] A paper lace automatic printing device described in conjunction with accompanying drawings 1-5 includes a fuselage 10 and an operating chamber 39 provided in the fuselage 10, a turret 49 is provided for rotation in the operating chamber 39, and the The rotation of the turret 49 drives the supporting block 11 arranged on the left side of the rotating frame 49 to move along a rectangular track, thereby driving the rotating block 43 arranged on the bottom wall of the supporting block 11 to move along a rectangular track, and the rotating block 42 moves At the same time, the printing head 88 arranged on the left side of the rotating block 42 is driven to move along the rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com