Automatic cap printing equipment for industrial production

A printing and equipment technology, which is applied in the field of automatic hat printing equipment for industrial production, can solve the problems of low work efficiency, time-consuming and laborious printing, etc., and achieve the effect of improving work efficiency and facilitating work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

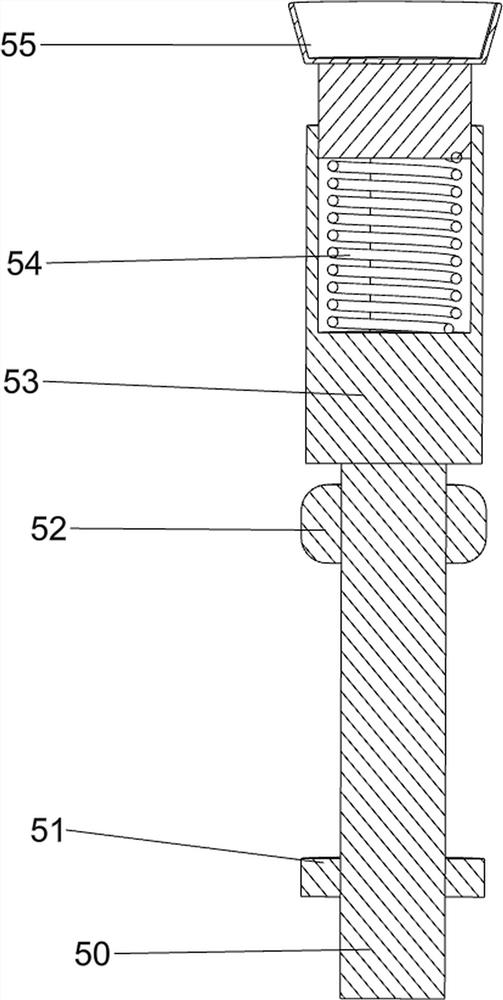

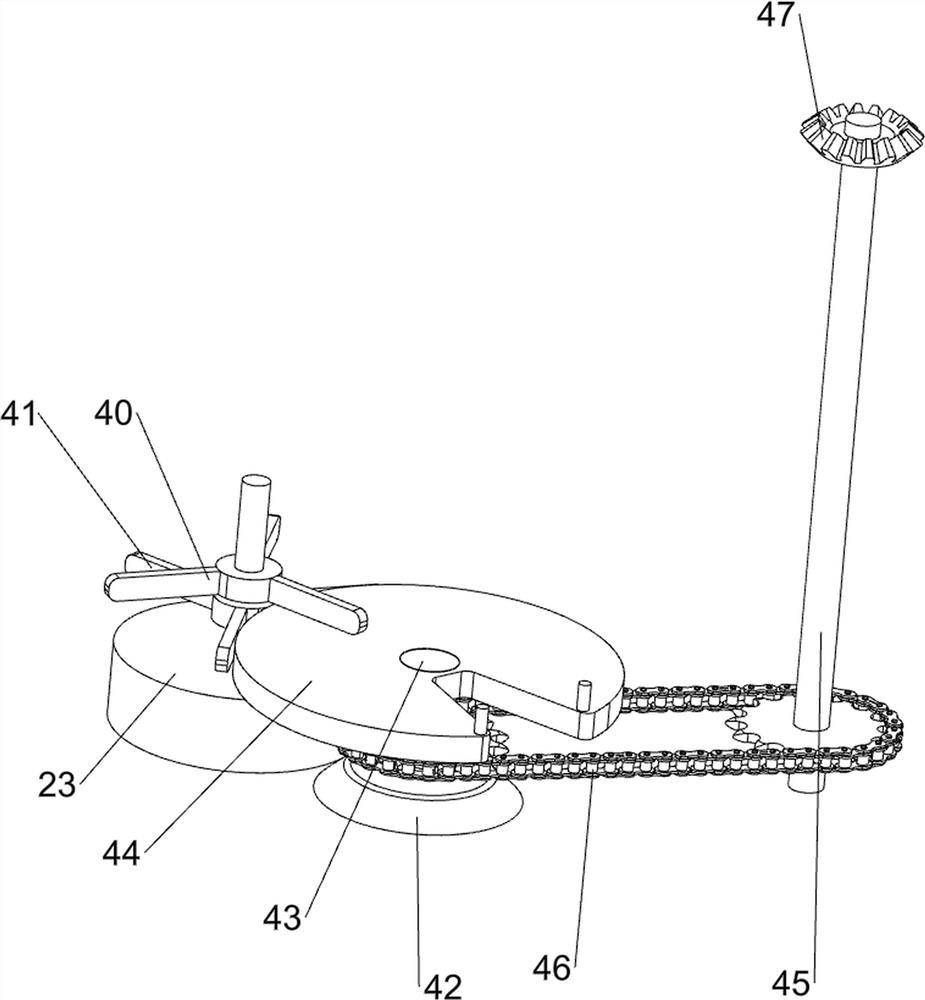

[0024] A kind of cap automatic printing equipment for industrial production, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a bottom plate 1, a transport mechanism 2, a stamp mechanism 3, a transmission mechanism 4 and a charging mechanism 5. The transport mechanism 2 is provided on the front side of the top of the bottom plate 1, and the stamp mechanism 3 is provided on the rear side of the top of the bottom plate 1. The right side of the top of the bottom plate 1 A transmission mechanism 4 is arranged on the side, and a charging mechanism 5 is arranged on the transportation mechanism 2 .

[0025] The transportation mechanism 2 includes a first support plate 20, a first transmission member 21, a second support plate 22, a second transmission member 23, a pulley assembly 24, a driving lever 25 and a support assembly 26, and the left and right sides of the top front side of the bottom plate 1 Two first support plates 20 are provided,...

Embodiment 2

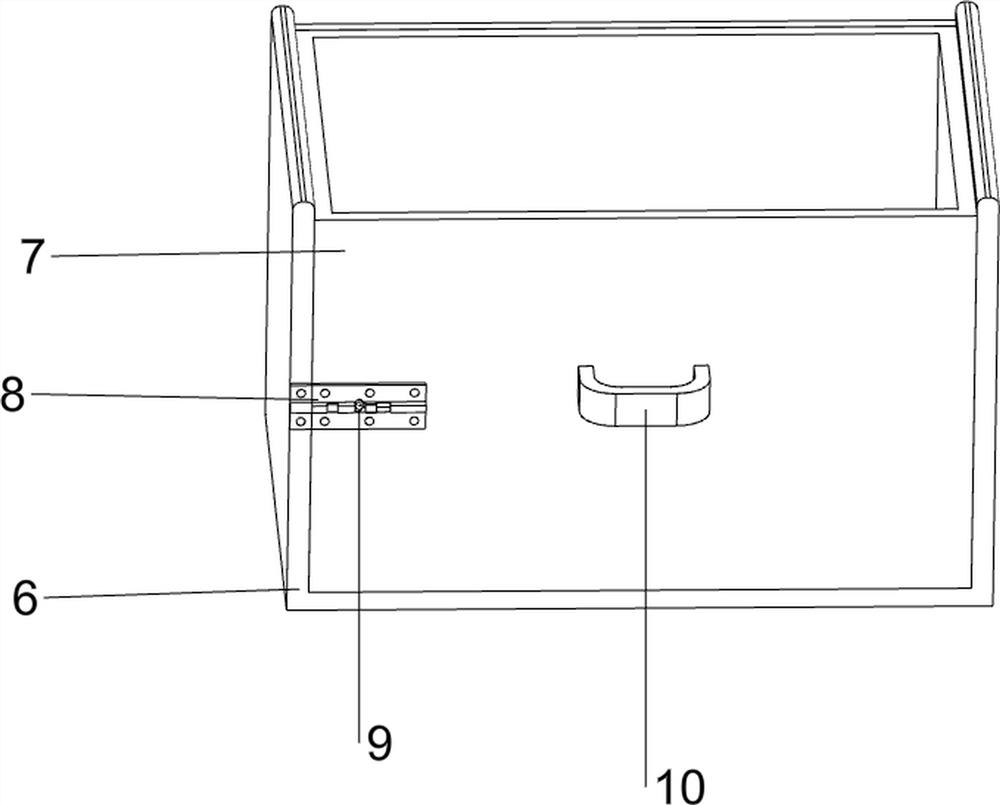

[0031] On the basis of Example 1, such as Figure 6 As shown, it also includes an outer box 6, an inner box 7, a lock 8, a latch 9 and a pull ring 10, the front right part of the bottom plate 1 top is provided with an outer box 6, and the inner box 7 is slidingly provided with the outer box 6, In the middle of the left part of the front side of the inner box 7 and the middle of the left part of the front side of the outer box 6, a lock catch 8 is provided, and a latch 9 is slidably provided on the lock catch 8 on the right side, and the latch 9 cooperates with the lock catch 8 on the left side. A pull ring 10 is provided at the middle part of the front side of the case 7 .

[0032] When people take off the printed hat, they can put the printed hat in the inner box 7, and when all the hats are printed, turn the latch 9 to the right, so that the latch 9 is separated from the left lock 8 , and then pull the pull ring 10 forward, so that the inner box 7, the lock 8 on the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com