A rice cake forming and printing equipment

A printing and equipment technology, applied in the field of rice cake forming and printing equipment, can solve the problems of slow printing speed and achieve the effect of compact printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

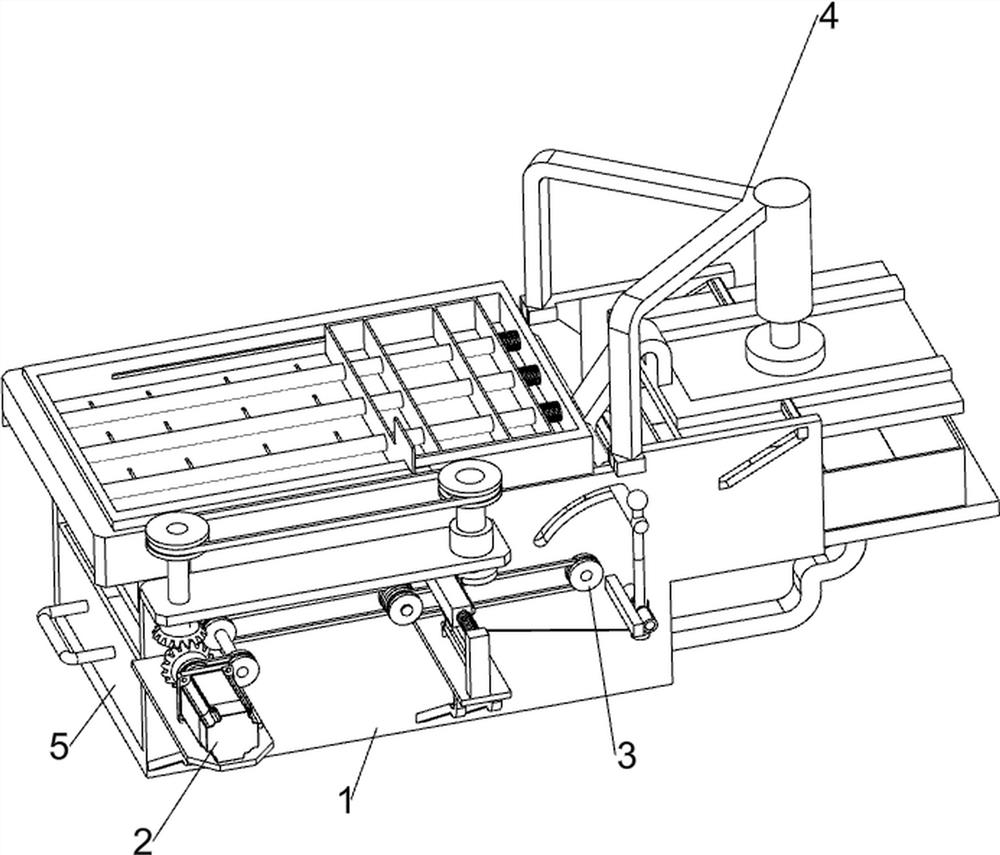

[0024] A rice cake forming and printing equipment, such as figure 1 As shown, it includes an installation box 1, a printing mechanism 2 and a transmission mechanism 3. The installation box 1 is provided with a printing mechanism 2, and the installation box 1 is provided with a transmission mechanism 3. The printing mechanism 2 cooperates with the transmission mechanism 3.

[0025] When the user needs to print the formed rice cake, the equipment can be used. First, the formed rice cake is placed in the installation box 1, and then the flour is poured into the printing mechanism 2. The flour is evenly sprinkled on the rice cake, and at the same time, the flour on the rice cake is printed, and then the printed rice cake is removed through the conveying mechanism 3 .

Embodiment 2

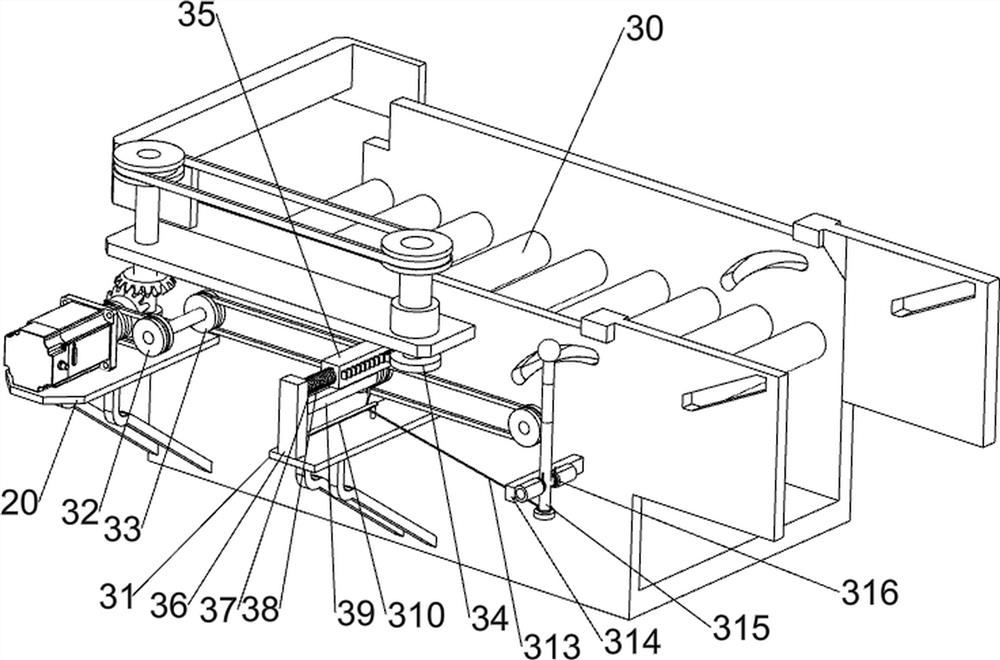

[0027] On the basis of Example 1, as Figure 2-5 As shown, the printing mechanism 2 includes a first support plate 20, a servo motor 21, a first bearing seat 22, a bevel gear set 23, a first shaft 24, a second support plate 25, a second bearing seat 26, and a second shaft 27 , the first pulley assembly 28, the dial block 29, the printing die 210, the guide rod 211, the first spring member 212 and the push plate 213, the front left side of the installation box 1 is provided with a first support plate 20, the first support plate A servo motor 21 is arranged on the upper part of the first support plate 20, a first bearing seat 22 is arranged on the rear side of the upper part of the first support plate 20, and a first rotating shaft 24 is rotatably arranged on the first bearing seat 22. The first rotating shaft 24 and the output shaft of the servo motor 21 A bevel gear set 23 is connected therebetween, a second support plate 25 is provided on the upper side of the front part of t...

Embodiment 3

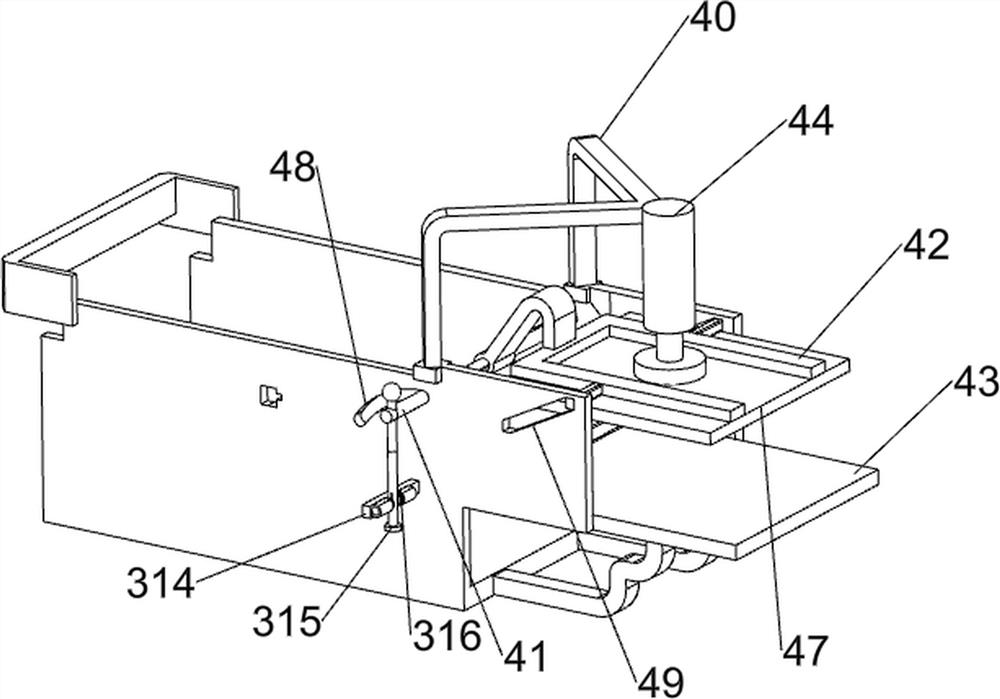

[0032] On the basis of Example 2, as Figure 5-7 As shown, it also includes a smoothing mechanism 4, the installation box 1 is provided with a smoothing mechanism 4, and the smoothing mechanism 4 includes a fixing frame 40, a first sliding rod 41, a pressing block 42, a fourth supporting plate 43, a sleeve The rod 44 , the fourth spring member 45 , the second sliding rod 46 and the pressing plate 47 , a fixing frame 40 is arranged on the right side of the upper part of the installation box 1 , a sleeve rod 44 is arranged on the right part of the fixing frame 40 , and the inner top of the sleeve rod 44 is provided with a first Four spring members 45 , a second sliding rod 46 is slidably arranged in the sleeve rod 44 , the second sliding rod 46 is connected with the fourth spring member 45 , the lower part of the second sliding rod 46 is provided with a pressure plate 47 , and the bottom of the right side of the box body 1 is installed. A fourth support plate 43 is provided. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com