Automatic printing device for cut velvet nano embroidery patterns

An automatic printing and pattern technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of loose textile threads, textile thread tightness adjustment, textile thread crossing disorder, etc., to achieve easy replacement, ensure accuracy, To ensure the effect of continuity and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

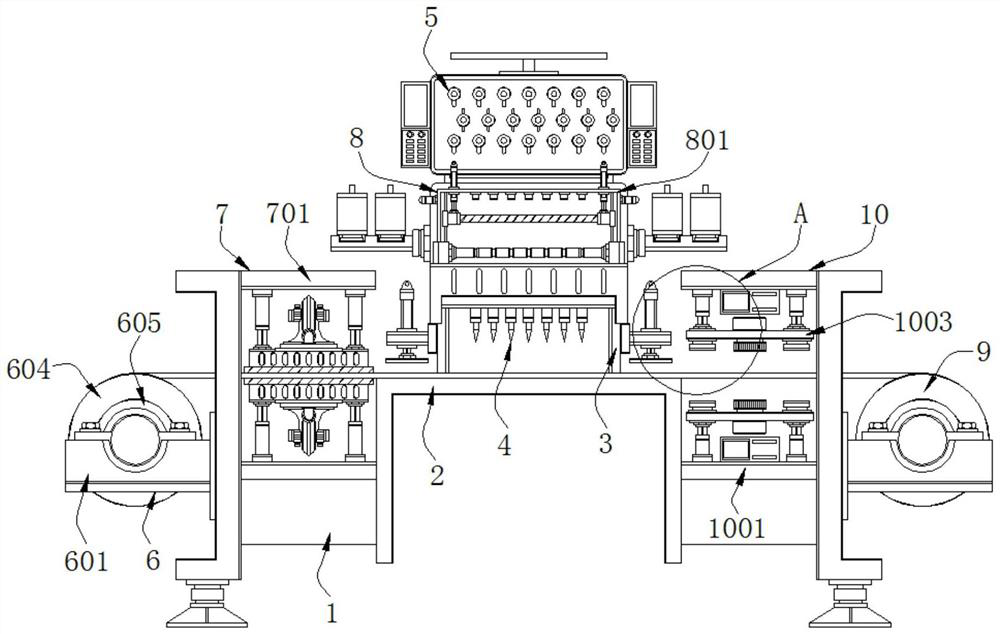

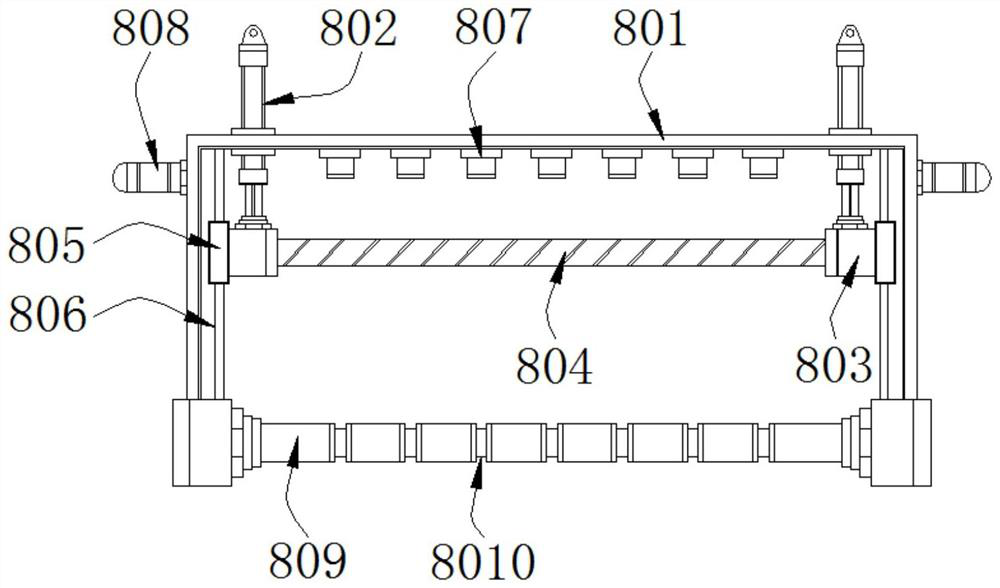

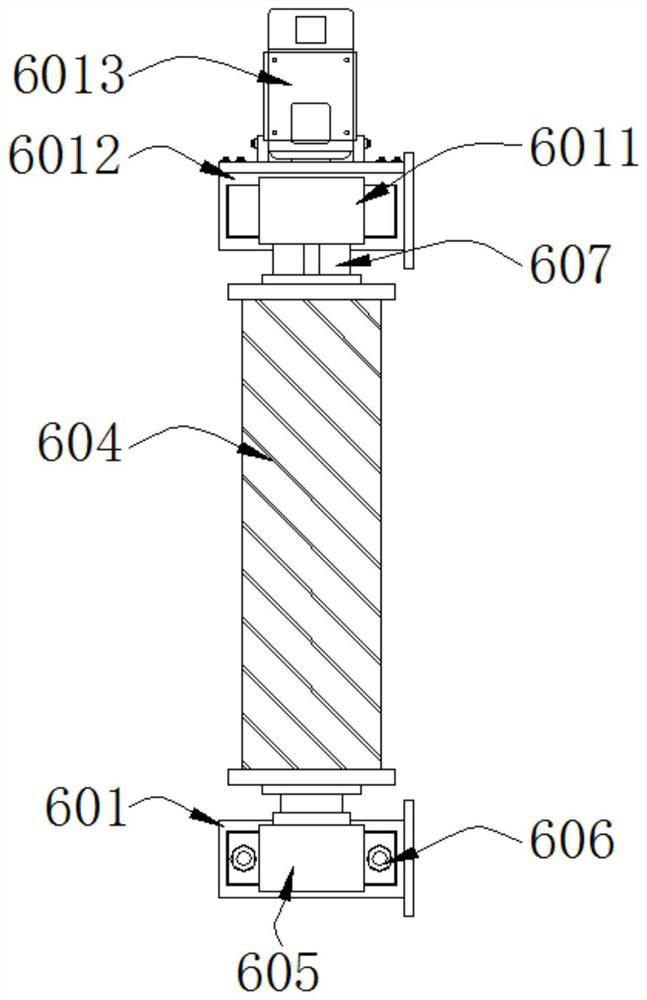

[0029] see Figure 1-7, the present invention provides a technical solution: an automatic printing device for cut velvet and embroidery patterns, including a base 1 and an adjustment assembly 8, a workbench 2 is arranged in the middle of the upper end of the base 1, and the middle of the upper end and rear end of the workbench 2 A printing seat 3 is provided, and the lower front end of the printing seat 3 is provided with a embroidery printing head 4, and the upper front end of the printing seat 3 is provided with a guide wheel 5, and the outer left side of the base 1 is provided with a feeding assembly 6 for cloth feeding, And the inner left side of the base 1 is provided with a leveling assembly 7 for cloth leveling, an adjustment assembly 8 for thread adjustment is arranged in the middle of the front end of the printing seat 3, and the adjustment assembly 8 includes a fixed frame 801, an adjustment cylinder 802, Connecting block 803, adjustment roller 804, adjustment slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com