Experimental test device for dry burning and melting of heating tube

A technology for testing equipment and heating tubes, which is applied in the direction of fuse testing, measuring electricity, and measuring devices. Exposure test, convenient dry burning fuse test, high safety test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

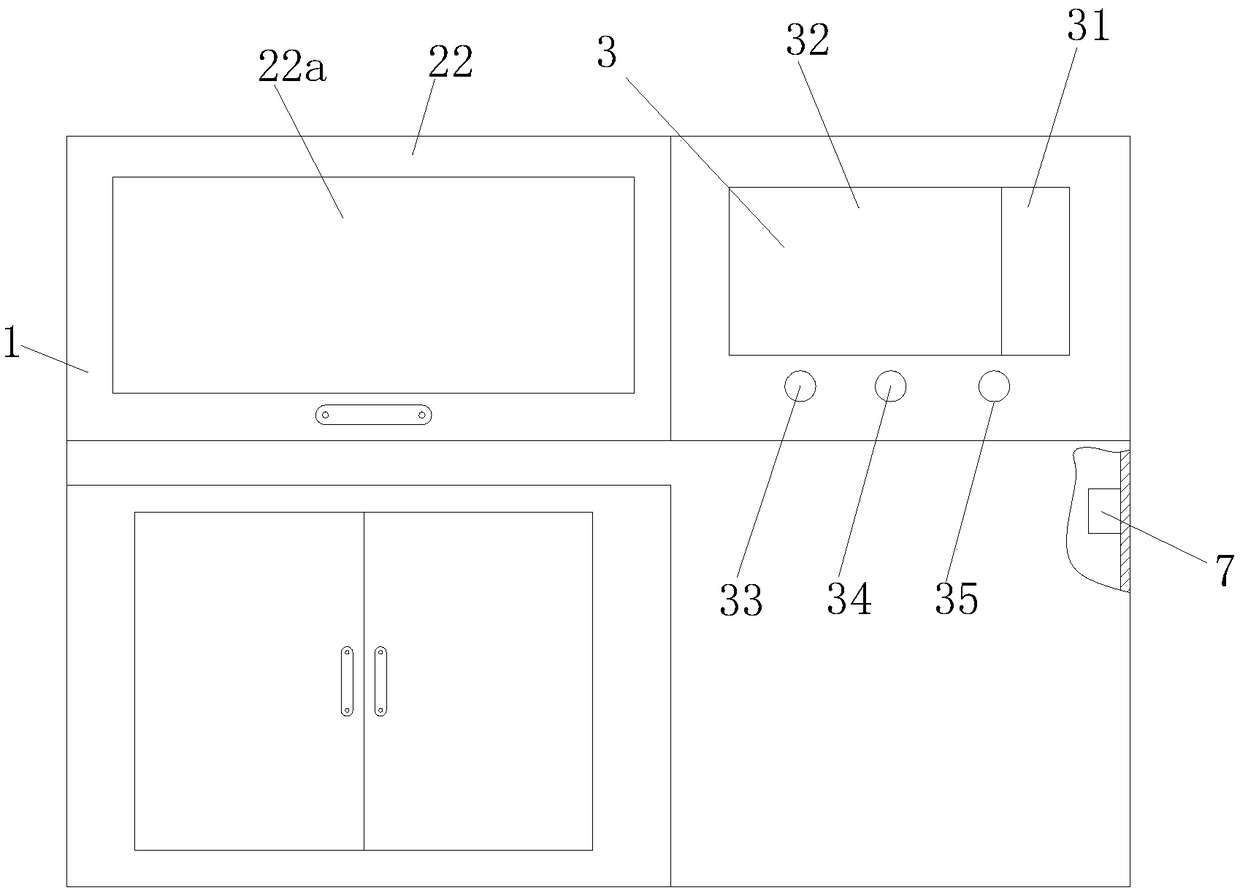

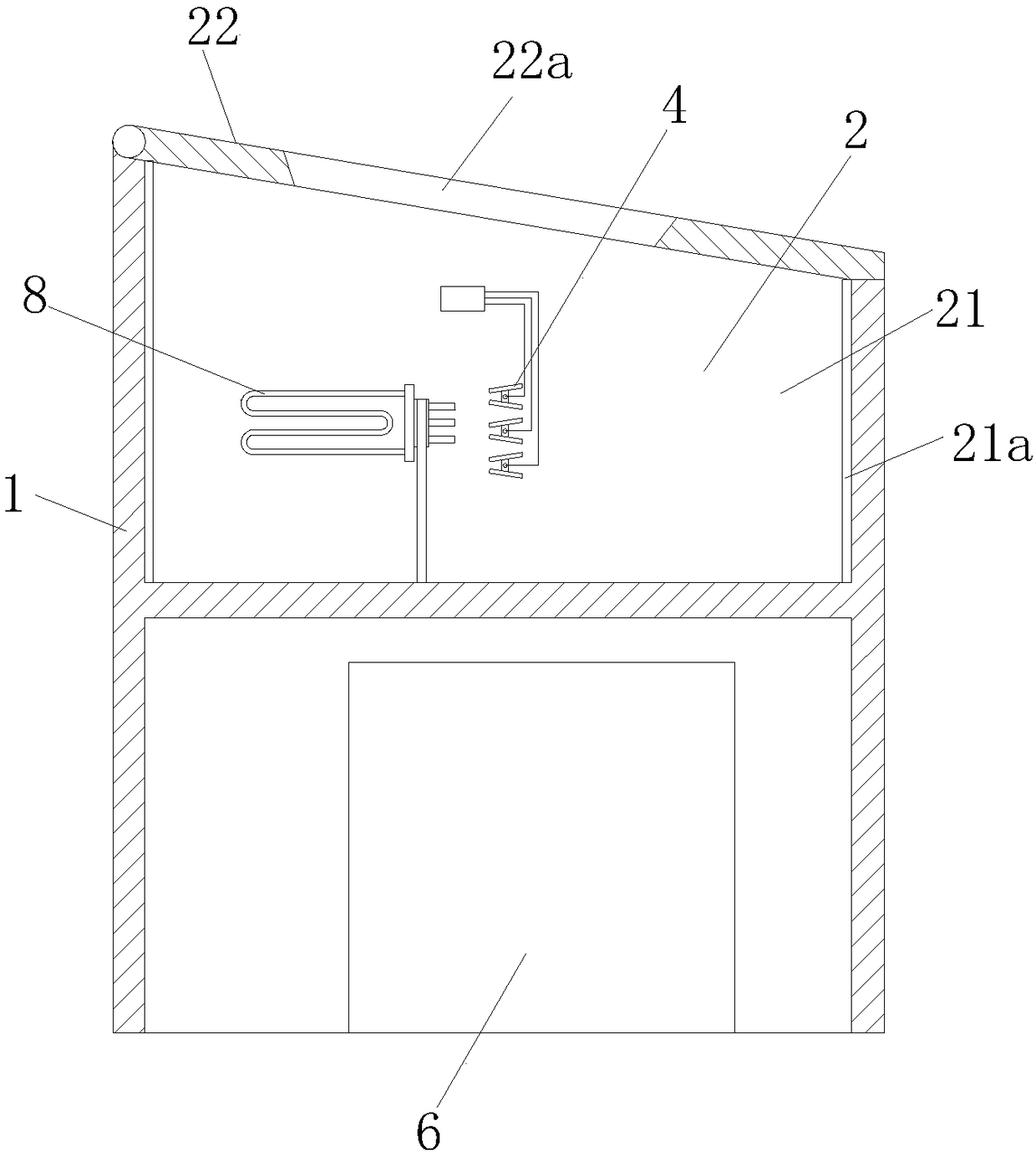

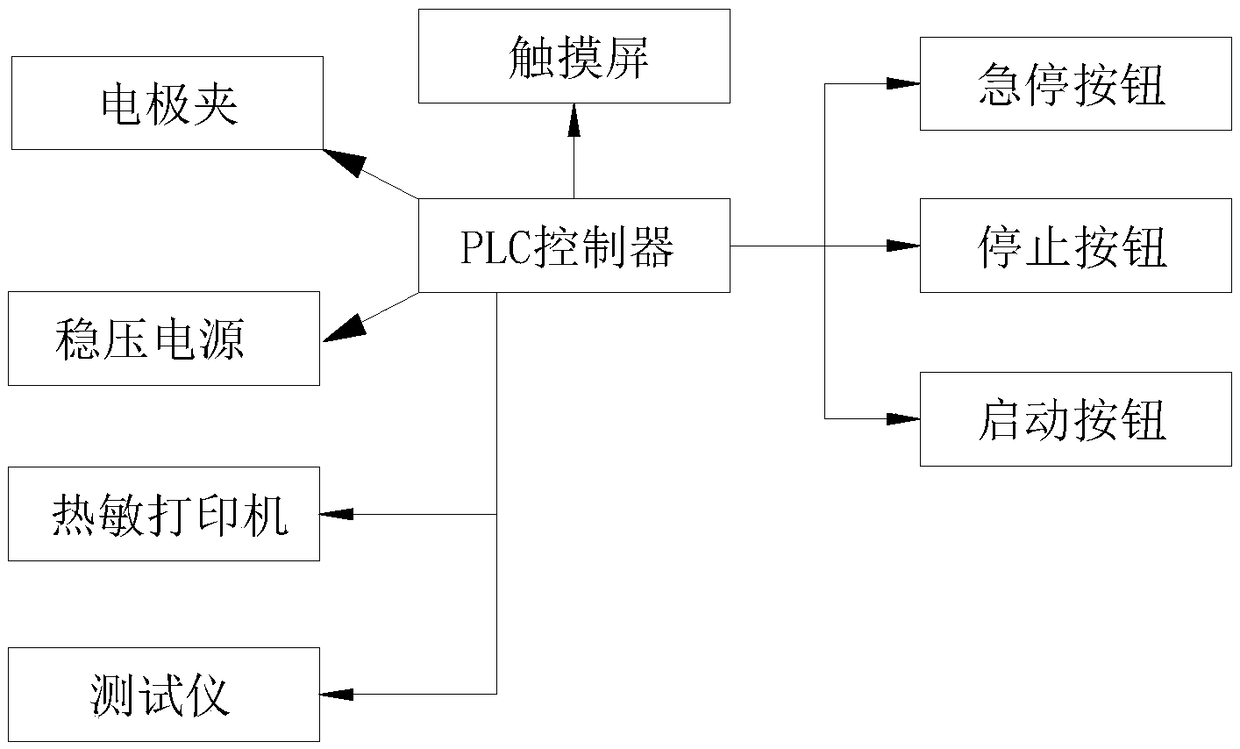

[0020] Such as Figure 1 to Figure 3 As shown, a heating tube dry-burning fusing experiment test equipment includes a frame 1, a flame-retardant operation box 2 is provided on the left side of the frame 1, and a test system 3 is provided on the right side, and the test system 3 is connected with The electrode holder 4 located in the flame-retardant operation box 2, the tester 5 and the programmable power supply 6 located at the lower side of the frame 1, the tester 5 is used to test power, current and resistance, and the frame 1 is equipped with The test system 3 is connected to a thermal printer 7 for printing test data.

[0021] The flame retardant operation box 2 includes a box body 21 with an open top and made of sheet metal parts, a cover plate 22 that is matched with the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com