Connection node and method for reinforced concrete conversion column wrapping reinforced concrete conversion beam

A technology for connecting nodes and connecting methods, which is applied in the direction of construction and building construction, can solve the problems of damage to the ends of rigid concrete beams or columns, many consumables, and complex envelope structures, and achieve structural stability, cost reduction, and convenience The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

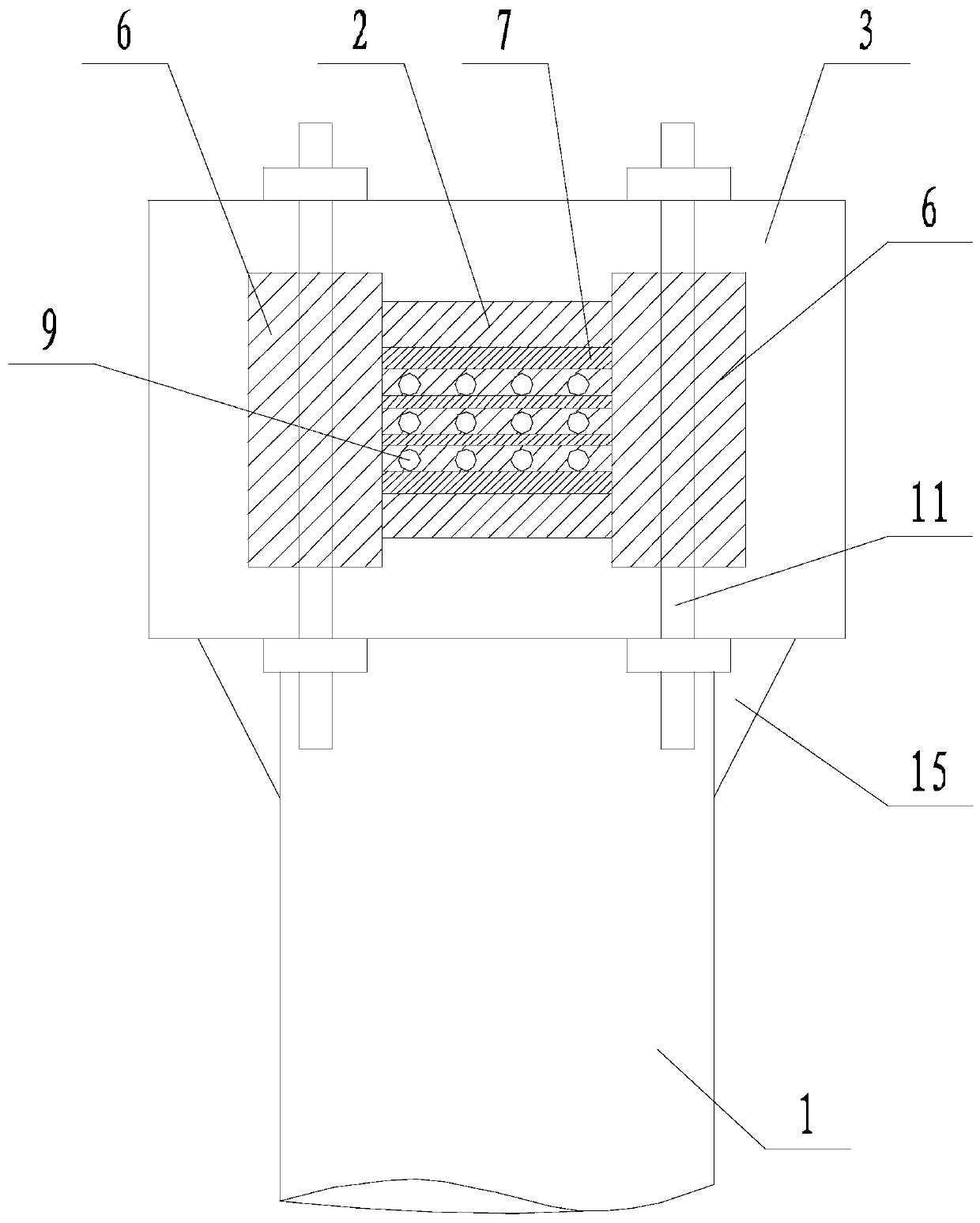

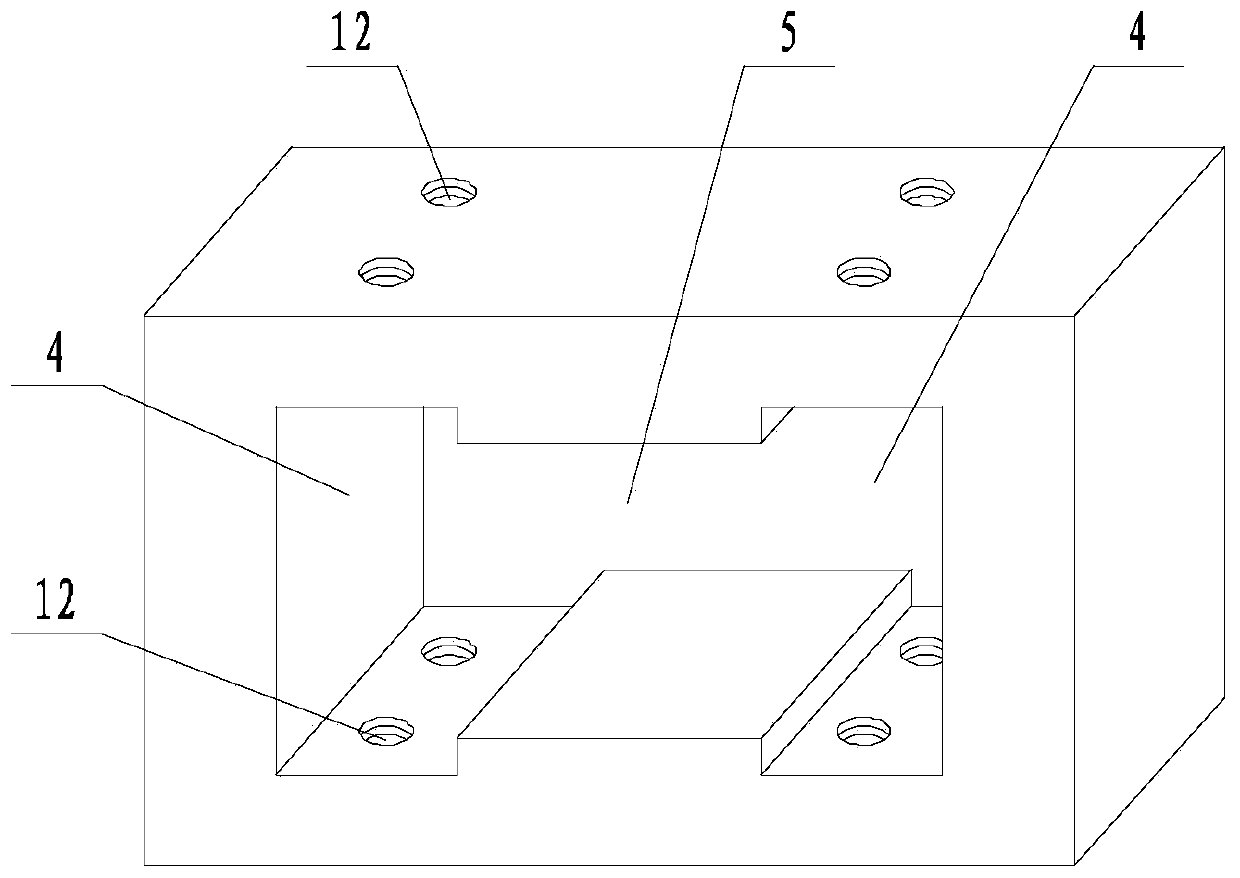

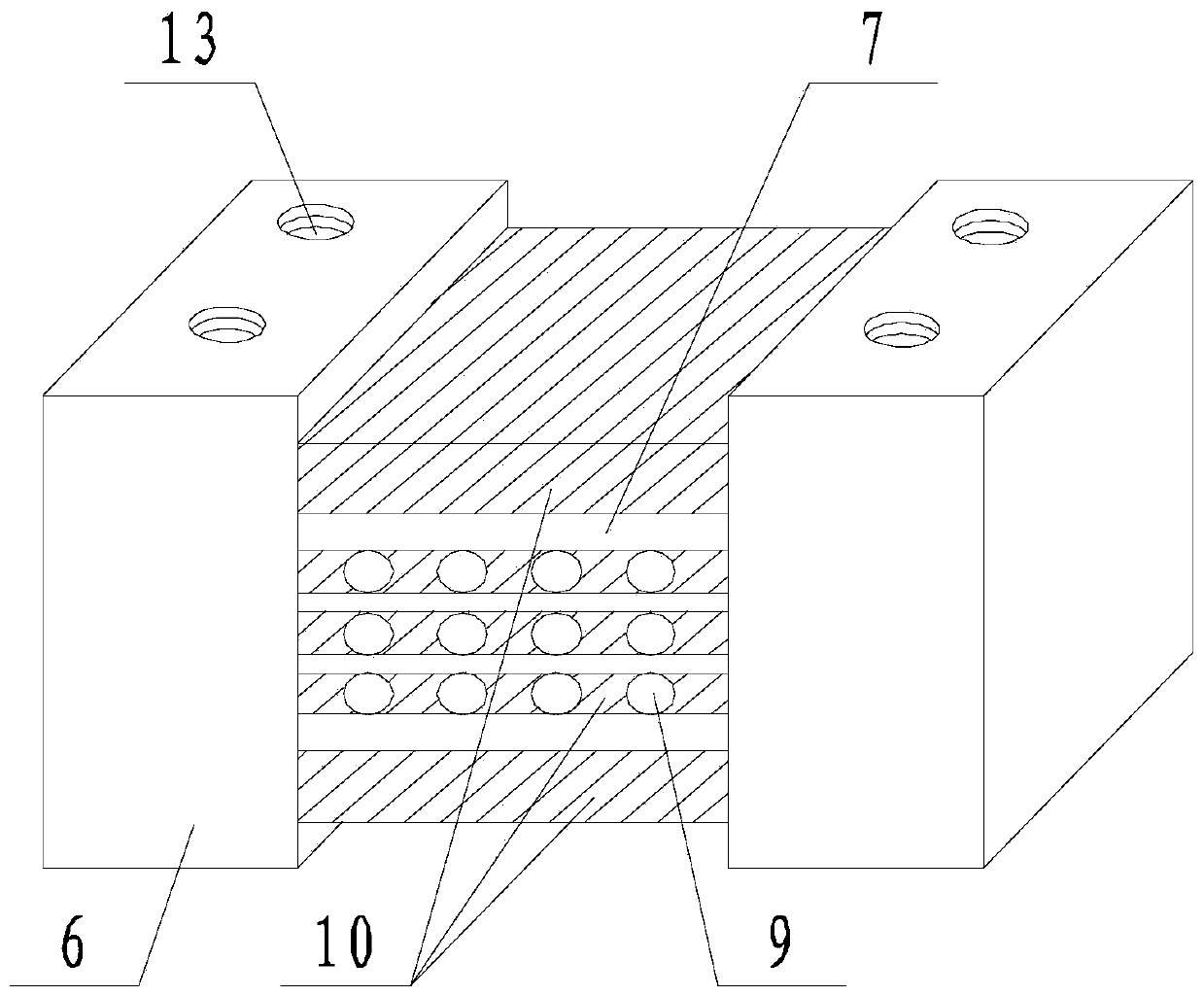

[0041] like Figure 1 to Figure 4 The connecting node of the stiffened concrete transfer column including the stiffened concrete transfer beam shown includes a stiffened concrete transfer column 1 and a stiffened concrete transfer beam 2, and the top fixed beam box 3 of the stiffened concrete transfer column 1, the The beam box 3 is provided with two through holes one 4 that run through the beam box 3 in the horizontal direction. It also runs through the beam box 3 in the horizontal direction; the stiffened concrete transfer beam 2 includes two steel pieces 1 6 respectively matched with the two through holes 4 , and the steel piece 2 7 is passed between the two steel pieces 6 Fixed connection, the thickness of the second steel part 7 is less than the height of the through hole two 5; several channels 8 are arranged in the second steel part 7, and a number of steel bars 9 pass through each channel, and the axes of the steel bars 9 are parallel On the axis of through hole 1 4 a...

Embodiment 2

[0048] like Figure 5 to Figure 8 The difference between this embodiment and Embodiment 1 of the connecting node of the stiffened concrete transfer column including the stiffened concrete transfer beam shown is that the cross-section of the through hole 4 in the vertical direction is a right-angled trapezoid, and the right-angled trapezoid The top side of the top side is longer than the bottom side, and the straight waist faces the direction of the second through hole 5; the cross section of the second through hole 5 in the vertical direction is square; the bottom surface of the second through hole 5 is higher than the bottom surface of the first through hole 4. The top surface of hole two 5 is lower than the top surface of through hole one 4 .

[0049] In addition, the beam box 3 is provided with two sets of first threaded through holes 12 facing each other on the upper and lower sides of the through hole one 4, and the first threaded through hole 12 facing the first threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com