A method of controlling an air cooler to start defrosting

An air cooler and air control technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems affecting refrigeration performance, instrument sensitivity limitation, and non-defrosting, so as to improve energy saving effect and start defrosting timing Accurate and reduce the effect of false defrosting or late defrosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described now in conjunction with accompanying drawing.

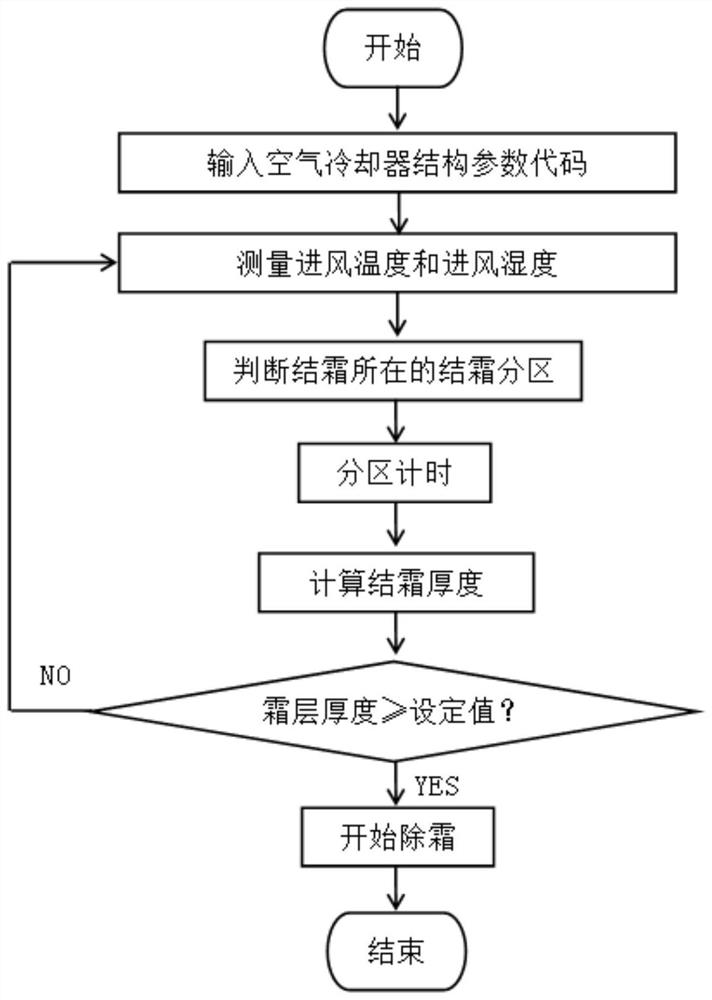

[0072] Such as figure 1 As shown, a method for controlling an air cooler to start defrosting includes the following steps:

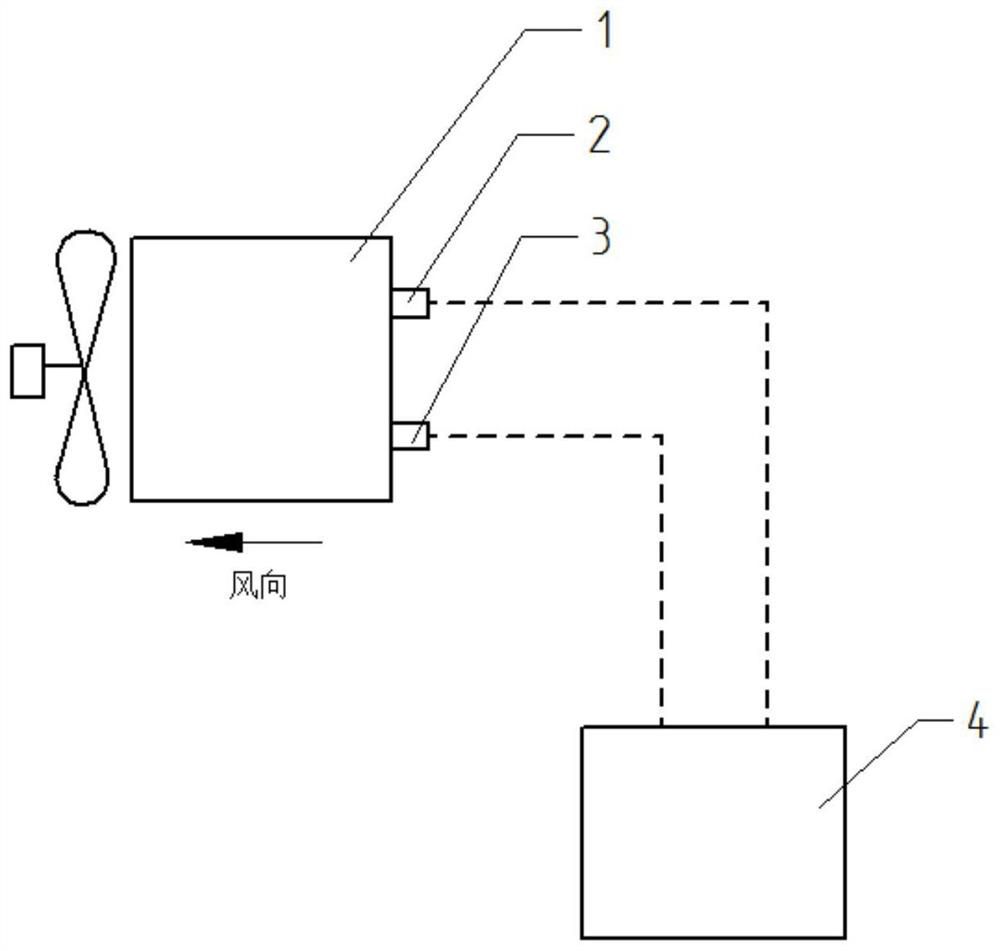

[0073] S101, dividing the frosting area corresponding to the air cooler 1 into five frosting zones, and installing a temperature sensor 2 and a humidity sensor 3 on the air inlet side;

[0074] S102, detecting the real-time inlet air temperature and inlet air humidity of the air cooler 1;

[0075] S103. According to the structural parameters of the air cooler 1, the inlet air temperature and the inlet air humidity, determine the frosting zone where the frosting 1 of the air cooler is located;

[0076] S104. Record the duration of each frosting partition where the air inlet temperature and air inlet humidity of the air cooler 1 are located, and record as:

[0077] t A , t B , t C , t D , t E ;

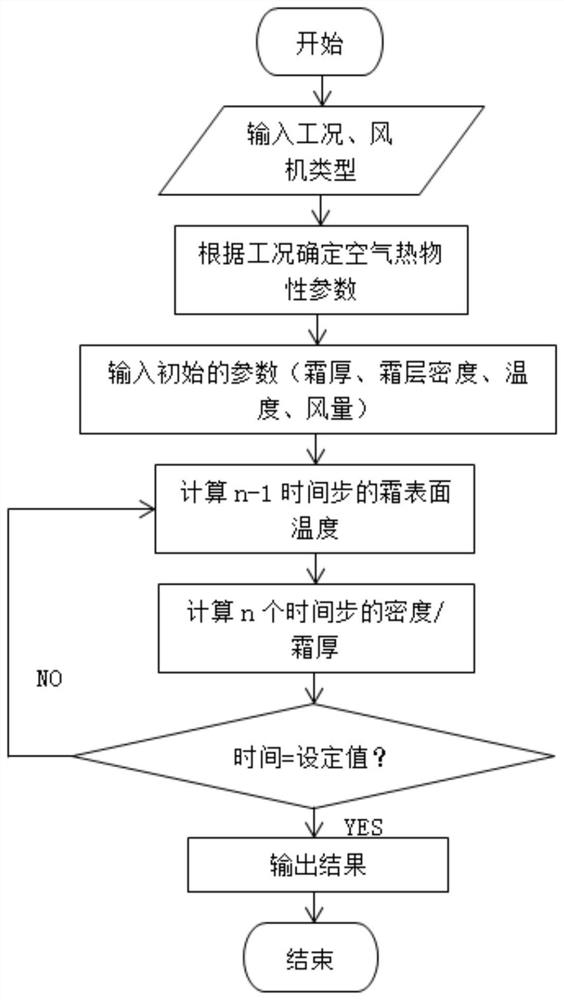

[0078] S105. Calculate the accumulative frost laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com