Chamfering and tapping integrated machine

An integrated machine and chamfering technology, applied in the field of workpiece processing to achieve the effect of protecting the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

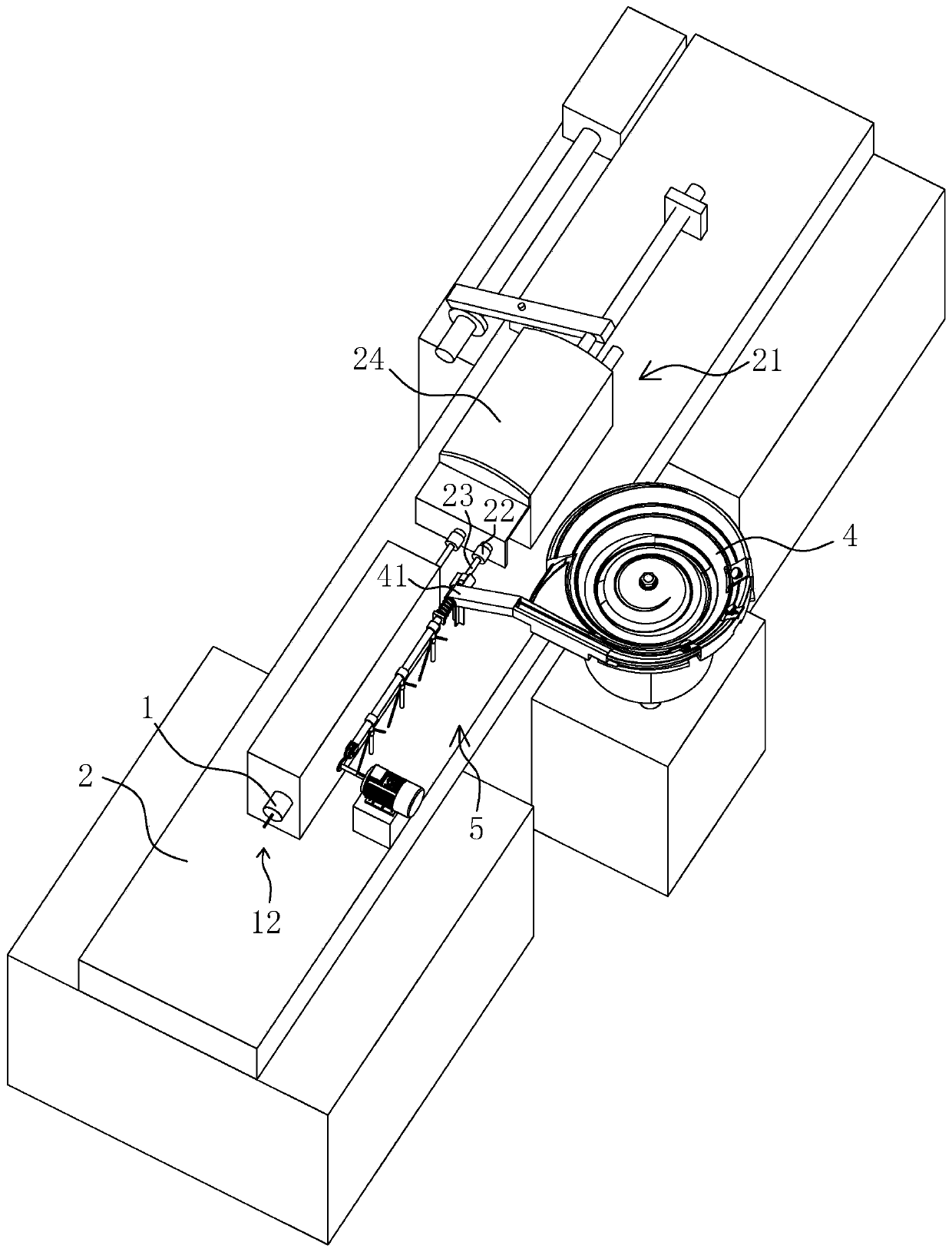

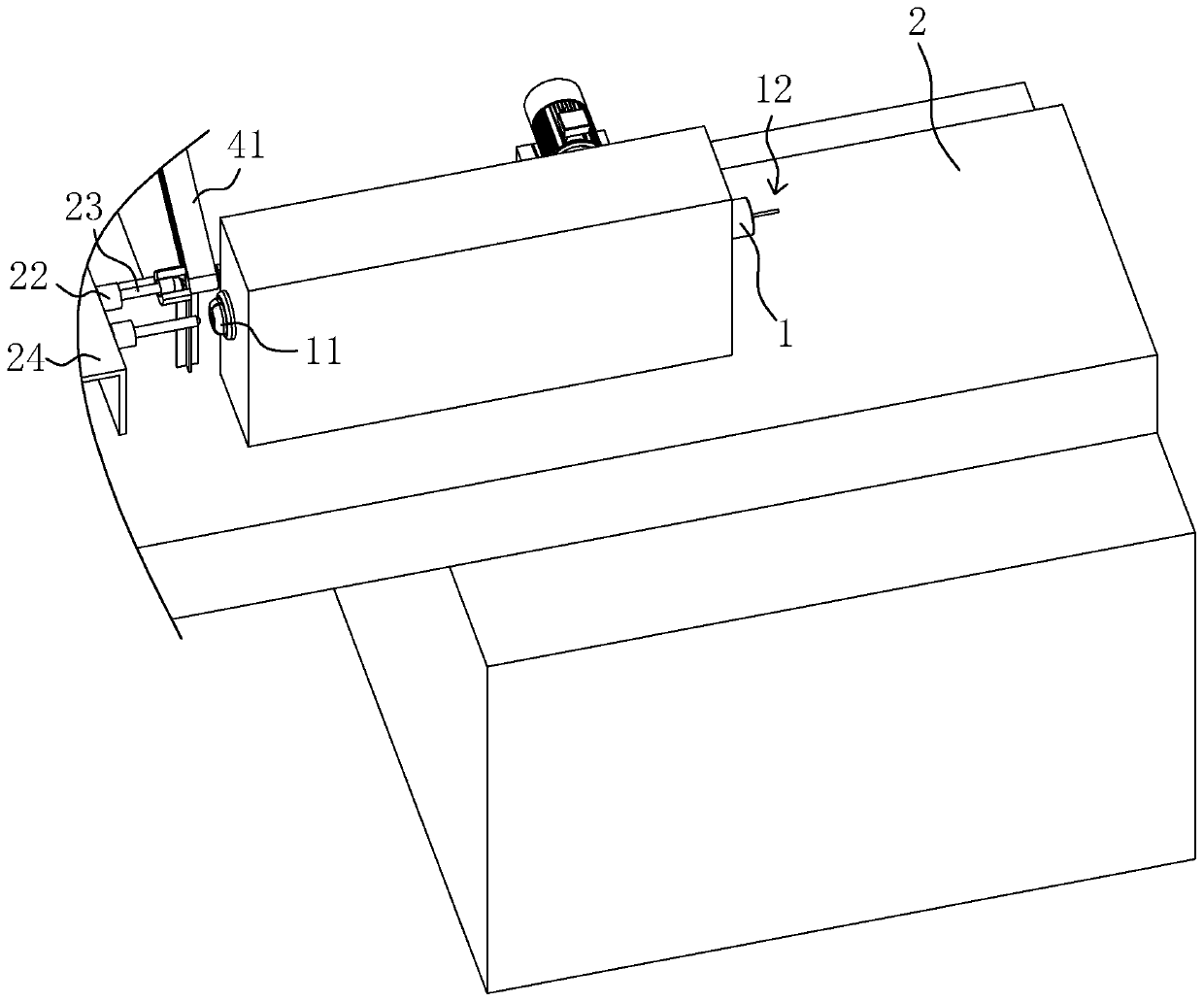

[0045] refer to figure 2 and image 3 , is an integrated chamfering and tapping machine disclosed in the present invention, including a placing table 2 for placing a rotating cylinder 1, the rotating cylinder 1 is rotatably set on the placing table 2, and one end of the rotating cylinder 1 is provided with a clamping head 11, The other end of the rotary drum 1 is provided with a pressurizing device 12, the pressurizing device 12 in the present invention includes an air pipe statically pierced in the rotating drum 1, and the end of the air pipe away from the rotating drum 1 is connected to an air compression pump, and an upper The feeding device 21, the feeding device 21 includes a rotating block 24 reciprocatingly rotating on the placement table 2, the rotating block 24 is reciprocatingly rotating against the clamping head 11, the rotating block 24 rotates ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap