Plastic particle material saving structure

A plastic granule and material-saving technology, which is applied in the field of plastic granule processing, can solve problems such as easy splashing, and achieve the effects of ensuring stability, improving efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

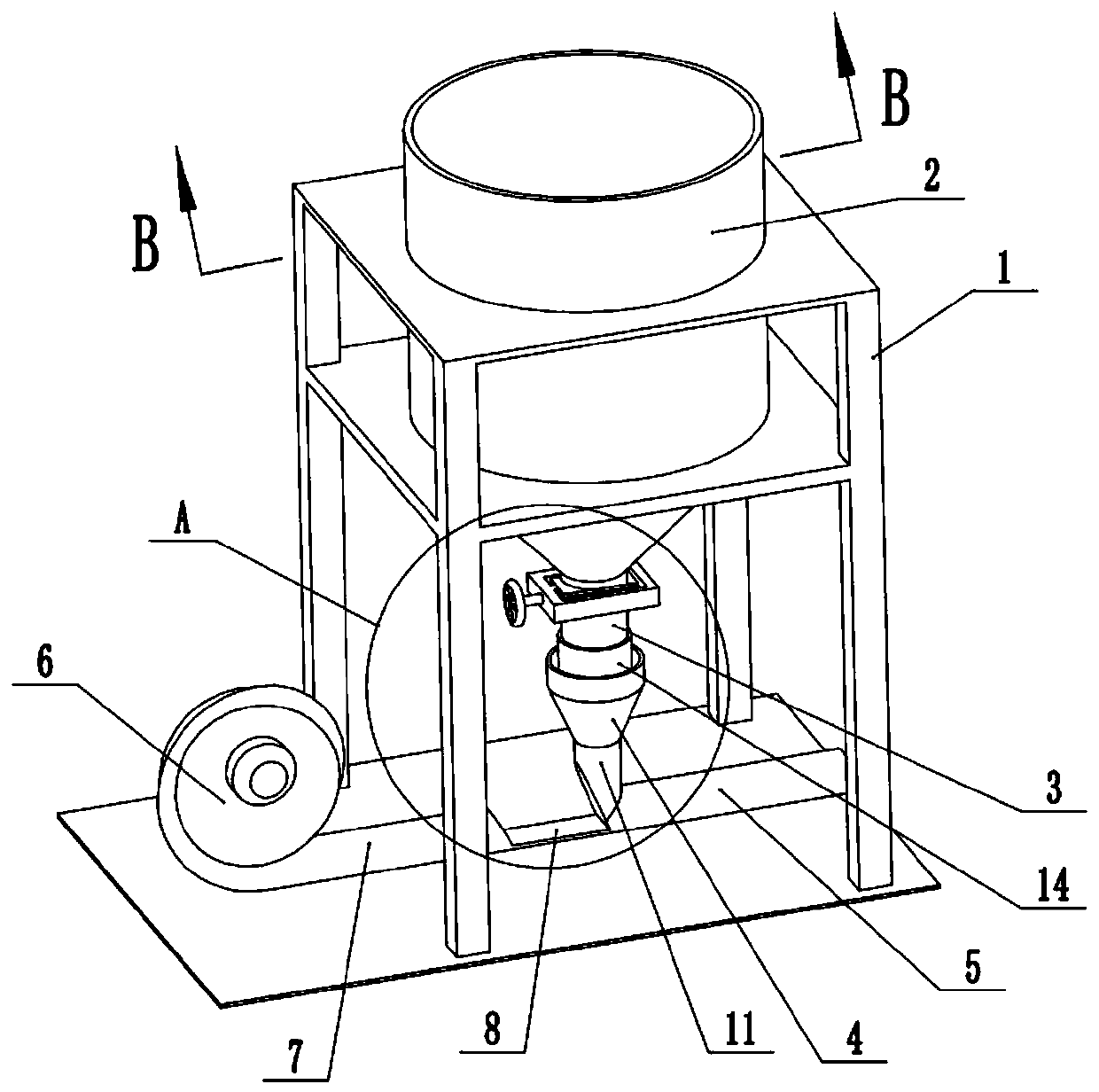

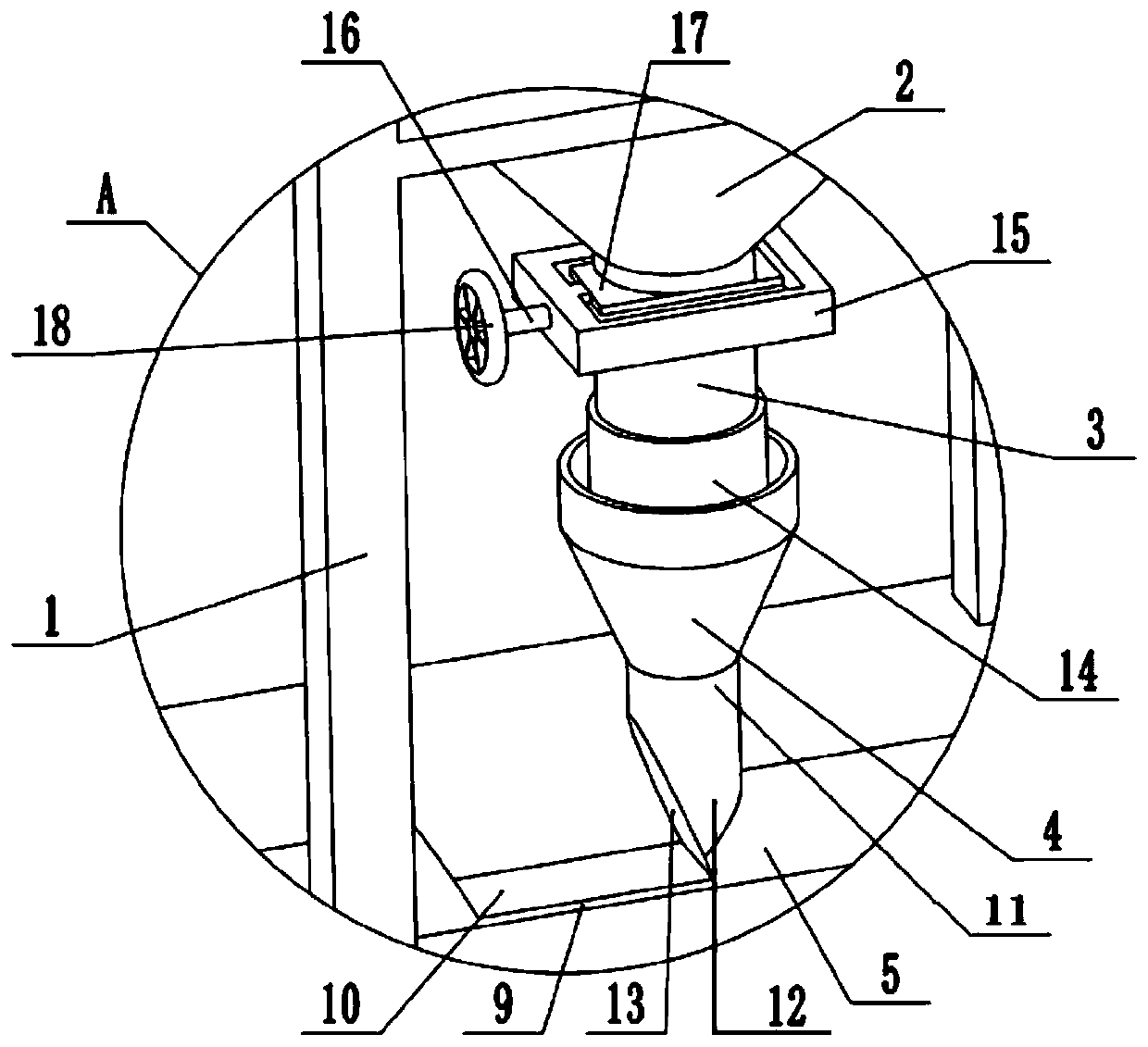

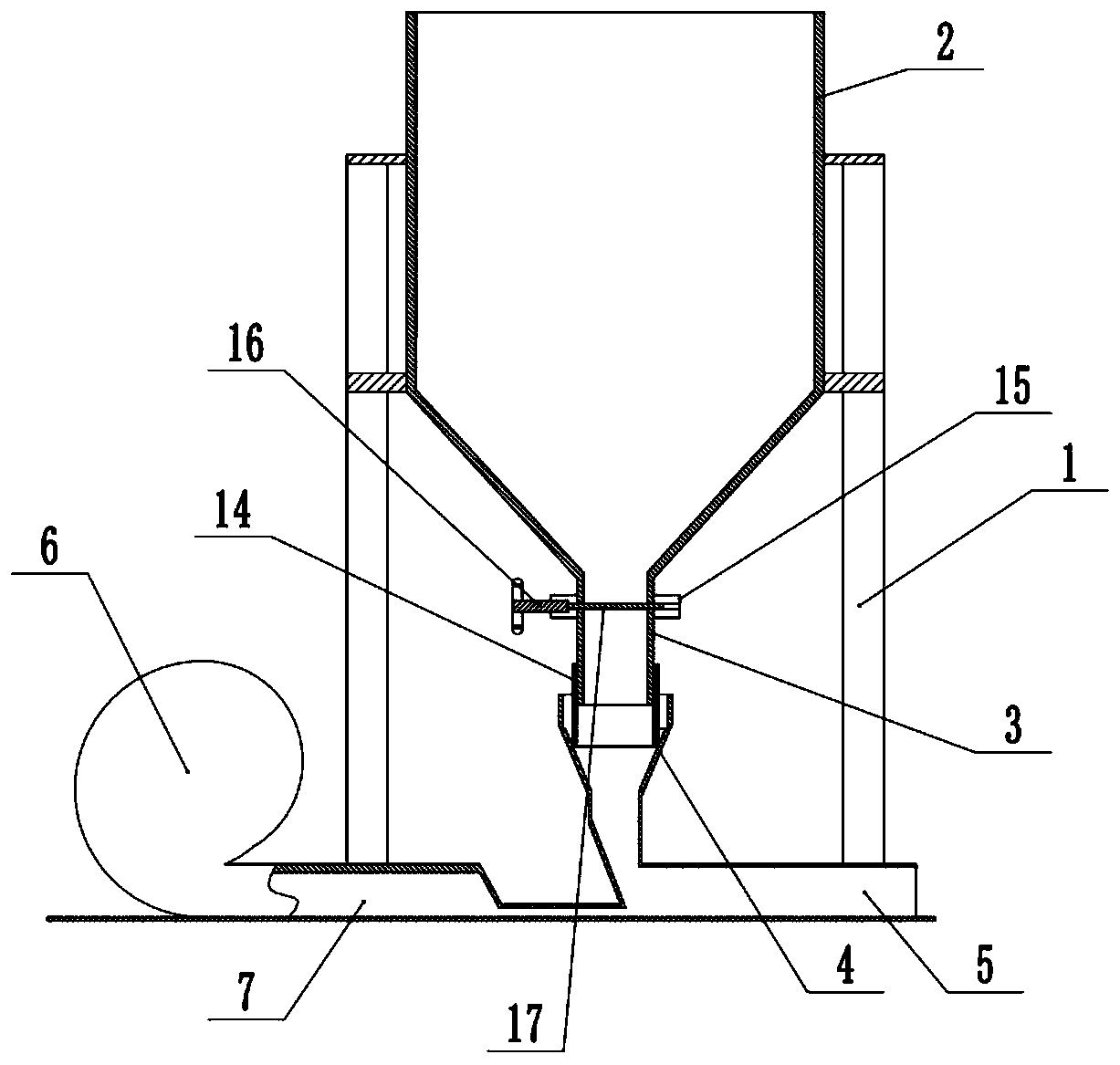

[0037] Embodiment one is basically as figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 As shown, the material-saving structure of plastic particles includes a bracket 1 and a storage hopper 2 welded on the bracket 1. The storage hopper 2 is funnel-shaped as a whole and is used for temporarily storing plastic particles inside. The bottom of the storage hopper 2 is welded with a discharge pipe 3. The bottom of the discharge pipe 3 is provided with a receiving pipe 4 for receiving plastic particles falling from the discharge pipe 3, and the lower end of the receiving pipe 4 is connected with a horizontally arranged feeding pipe 5, and the left side of the feeding pipe 5 is provided for driving the feeding pipe. 5. The power mechanism for conveying plastic particles.

[0038] Such as figure 1 As shown, the power mechanism includes a fan 6 and an air guide pipe 7, the fan 6 is fixedly connected to the ground by bolts, the air guide pipe 7 is located between the fan 6 an...

Embodiment 2

[0047] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the air guide pipe 7 and the feeding pipe 5 are arranged obliquely in a state of left high and right low, so that when the gas blown by the fan 6 enters the feeding pipe 5, the flow direction of the gas and the connection The plastic particles falling from the pipe 4 have an inclination angle, and the plastic particles are easier to change the direction of movement under the blown by the inclined air flow, so that the plastic particles at the junction of the receiving pipe 4 and the delivery pipe 5 can be quickly blown away, and the plastic particles can be more effectively prevented. Blockage occurs at the junction of the receiving pipe 4 and the delivery pipe 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com