Method for measuring and evaluating flexible gear in working state based on rigid gear parameters

A working state and evaluation method technology, applied in data processing applications, electrical digital data processing, special data processing applications, etc., can solve the problems of inability to measure and evaluate the performance of flexible wheels, and achieve the effect of direct evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A method for measuring and evaluating a flexible spline under working conditions based on rigid spline parameters, comprising the following steps:

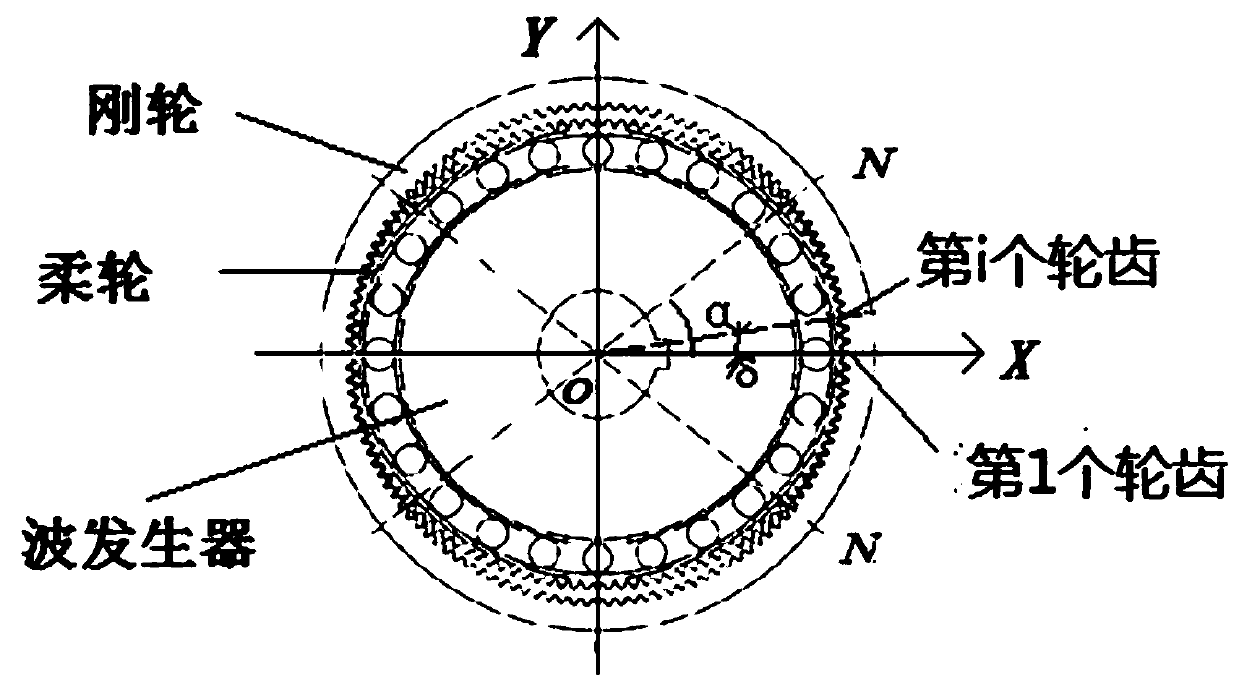

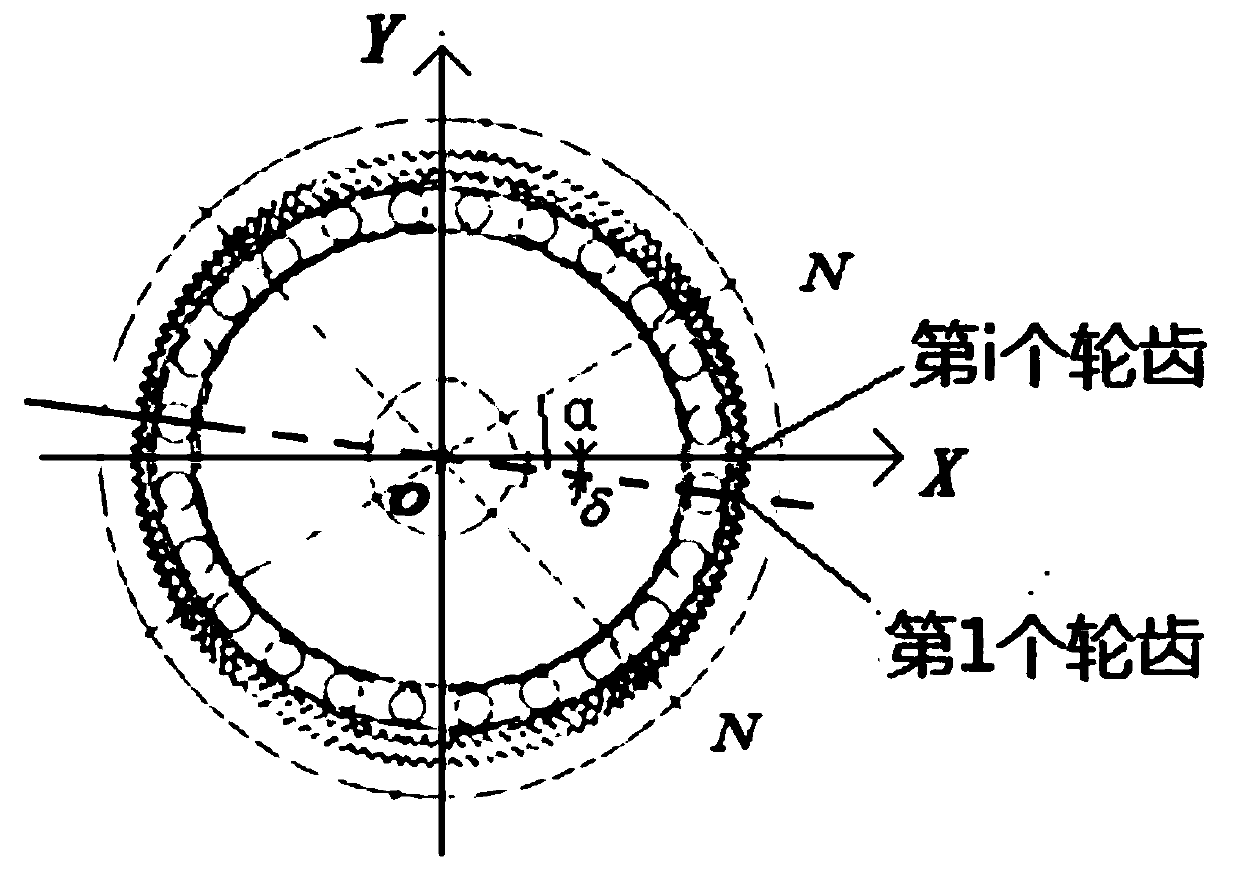

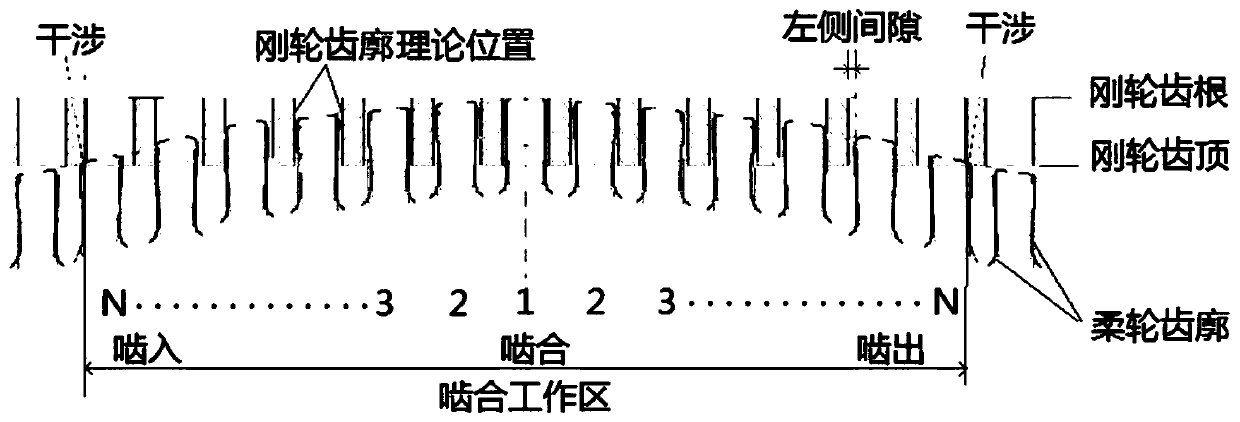

[0025] Step 1), see figure 1 , on the reduction device of the harmonic gear, first establish the Oxy coordinate system based on the parameters of the rigid wheel, O coincides with the center of rotation of the rigid wheel, the teeth of the flexible wheel are symmetrical with respect to the X axis, and the direction of the long axis of the wave generator and the X axis The direction is the same, the short axis of the wave generator is consistent with the direction of the Y axis; under the action of the wave generator, the flexspline is deformed, so that the gear teeth near the long axis of the wave generator participate in meshing, and the gear teeth near the long axis of the wave generator are far away Do not participate in the meshing, that is, the teeth in the four gray areas that are symmetrical to the X axis participate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com