Fire extinguishing element for flameless explosion pressure relief device

A pressure relief device, flameless technology, used in packaging, fire rescue, transportation and packaging, etc., can solve the problems of reduced blocking performance, loss of explosion pressure relief, and increased blocking effect, achieving high pressure relief efficiency and preventing flames. The effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

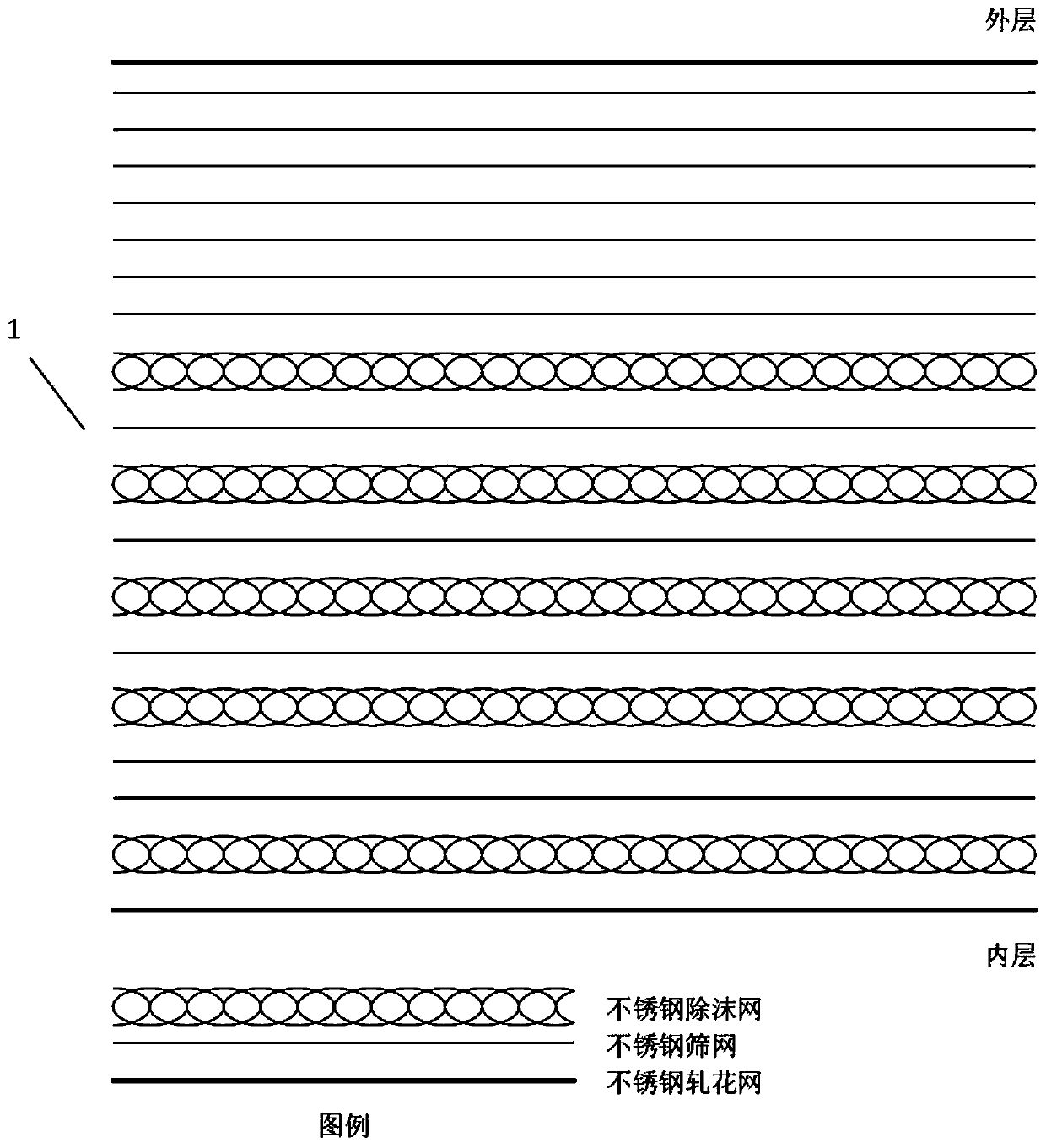

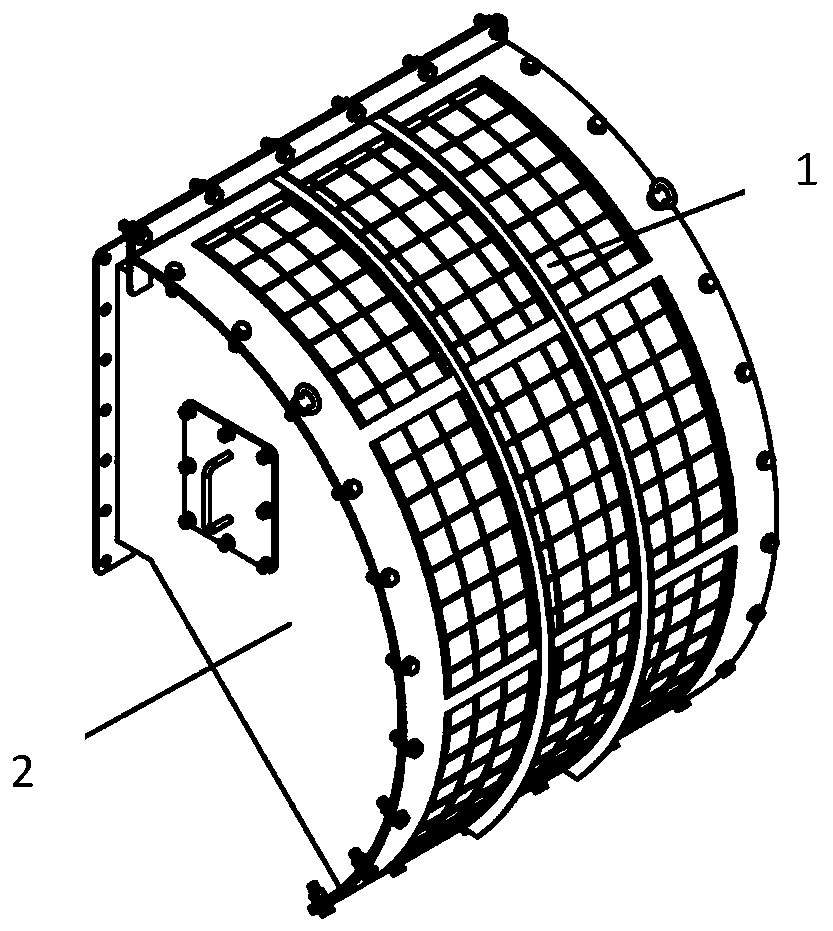

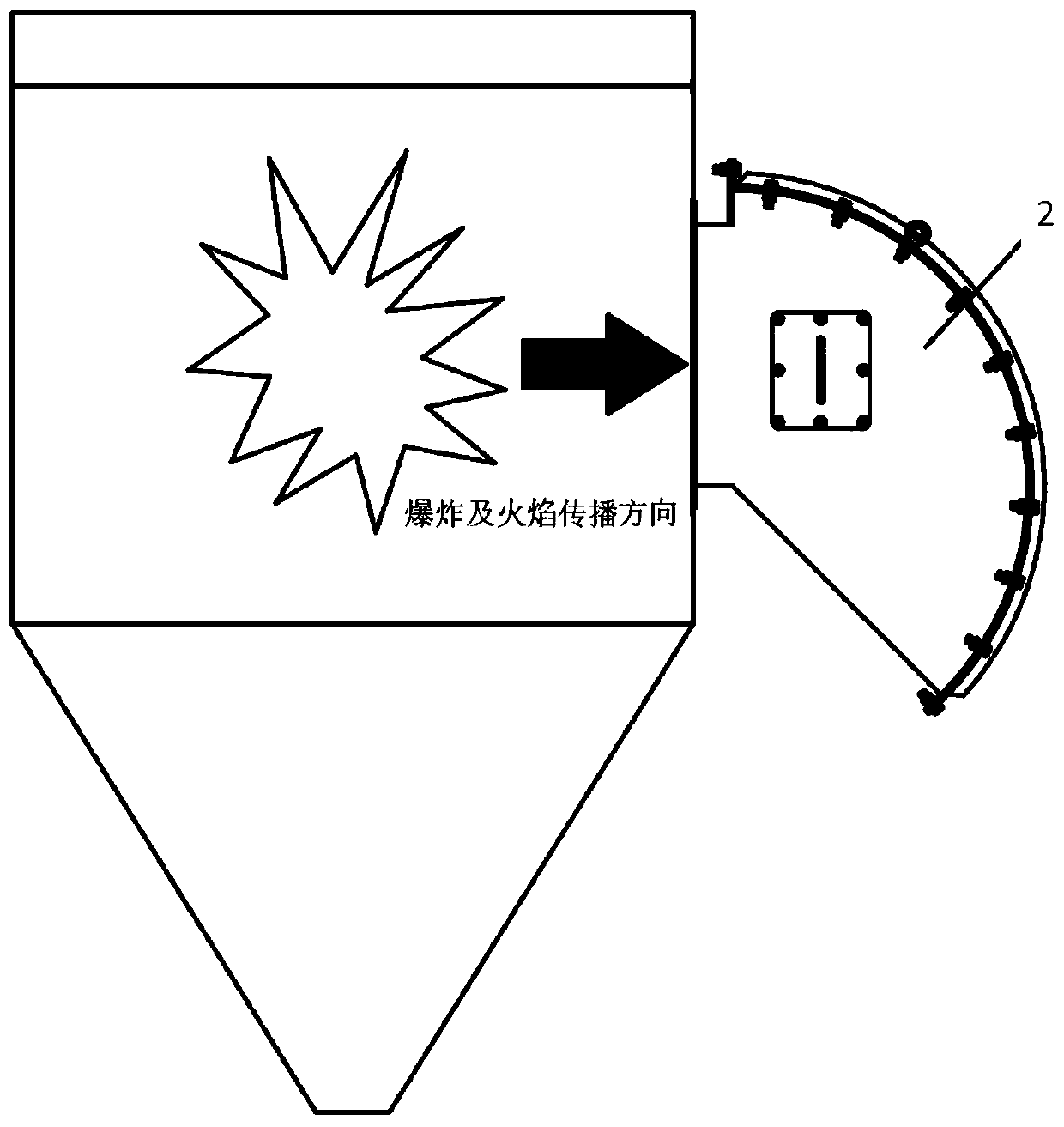

[0023] Such as figure 1 As shown, it is a structural schematic diagram of the fire extinguishing element used in the flameless explosion pressure relief device of the present invention. The fire extinguishing element 1 for flameless explosion pressure relief device 2 of the present invention is characterized in that:

[0024] The first layer and the 42nd layer of the fire extinguishing element 1 are all stainless steel embossed meshes with a wire diameter of 3mm and an aperture of 50mm;

[0025] The 2nd to 7th layers, the 10th to 15th layers, the 17th to 20th layers, the 22nd to 27th layers, and the 29th to 34th layers of the fire extinguishing element 1 are all stainless steel defoaming nets;

[0026] The 8th, 16th, 21st, 35th to 36th, 38th, and 40th to 41st layers of the fire extinguishing element 1 are all 15-mesh stainless steel mesh;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com