Binding operating mechanism for reinforcement cage of beam column of building

An operating mechanism and steel cage technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of complicated process of making steel cages, unbalanced force, long time for making steel cages, etc., and achieve the spacing between main bars The arrangement position is reliable and accurate, it is easy to popularize and use, and the effect of taking out is simple and labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

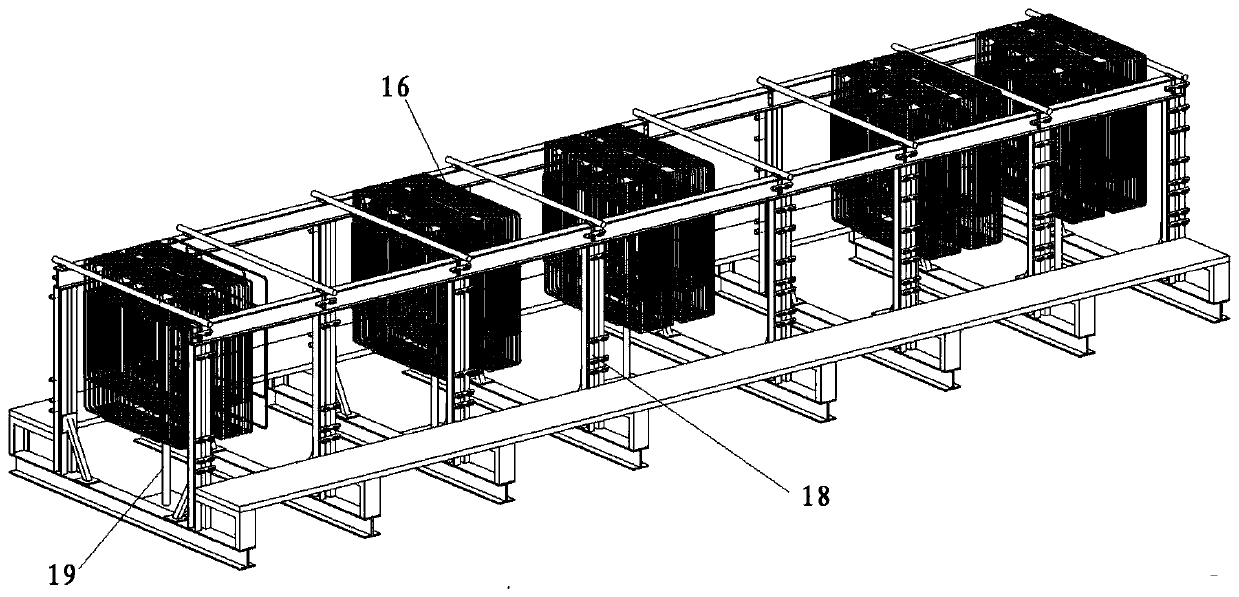

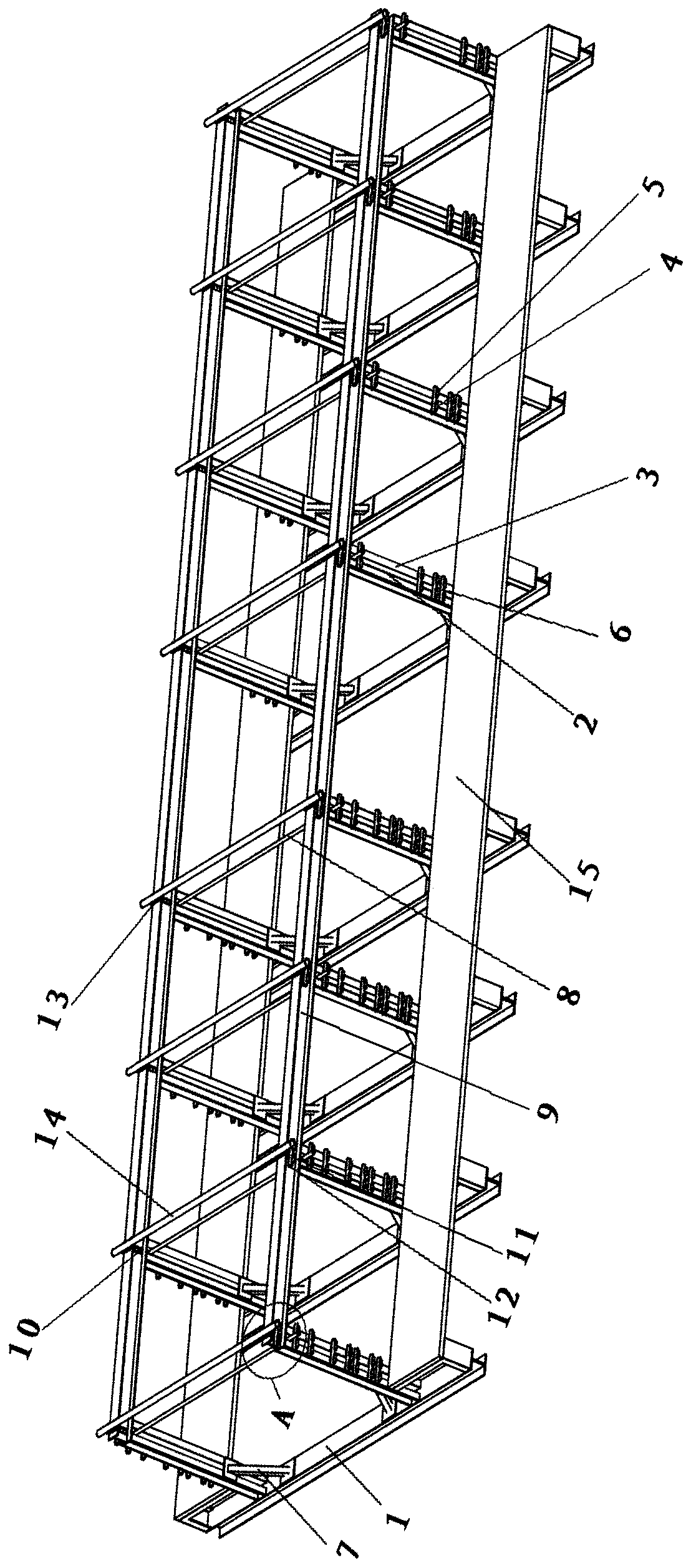

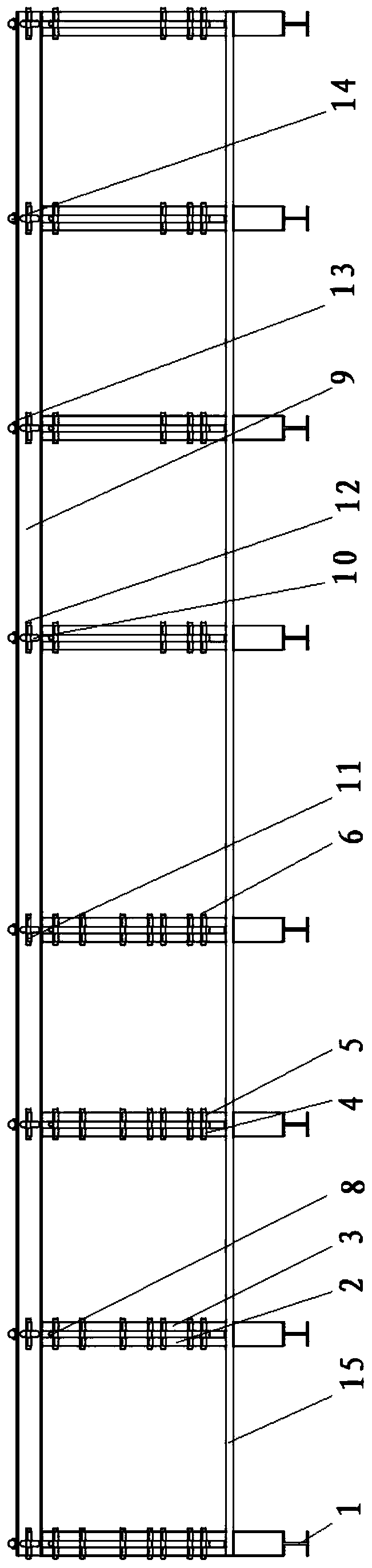

[0039] Such as Figure 1 to Figure 9 As shown, the present invention includes a main rib positioning frame 18 for locating the position of the main rib 17 and a plurality of stirrup suspension frames 19 that are all matched with the main rib positioning frame 18 and are used to support the hanging stirrup 16. The main rib positioning frame 18 includes two relative The top supporting steel beams 9 arranged in parallel, a plurality of steel cage load-bearing bars 14 arranged in parallel along the length direction of the top supporting steel beams 9 on the top of the two top supporting steel beams 9 and a plurality of parallel top supporting steel beams 9 along the length direction Be arranged on the supporting positioning mechanism at the bottom of the two top supporting steel beams 9, the number of the supporting positioning mechanism is equal to the number of the steel cage load-bearing bars 14 and correspond one by one, and the side walls of the top supporting steel beams 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com