Screw driving machine of hoop for water feed pipe and water drainage pipe of washing machine

A screw-locking machine and screw-locking mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low production efficiency, and unsuitability for mass production, so as to reduce labor intensity and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

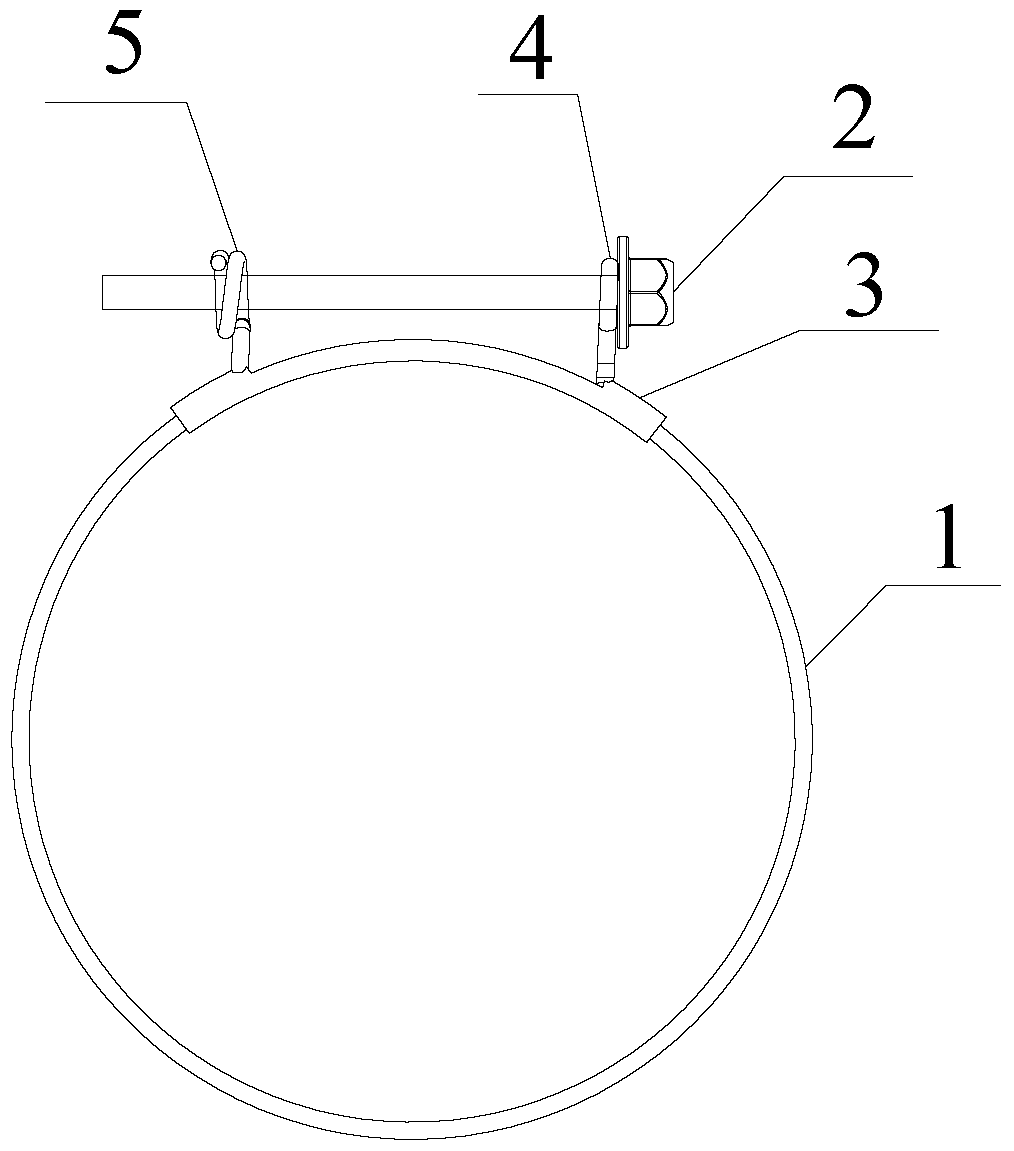

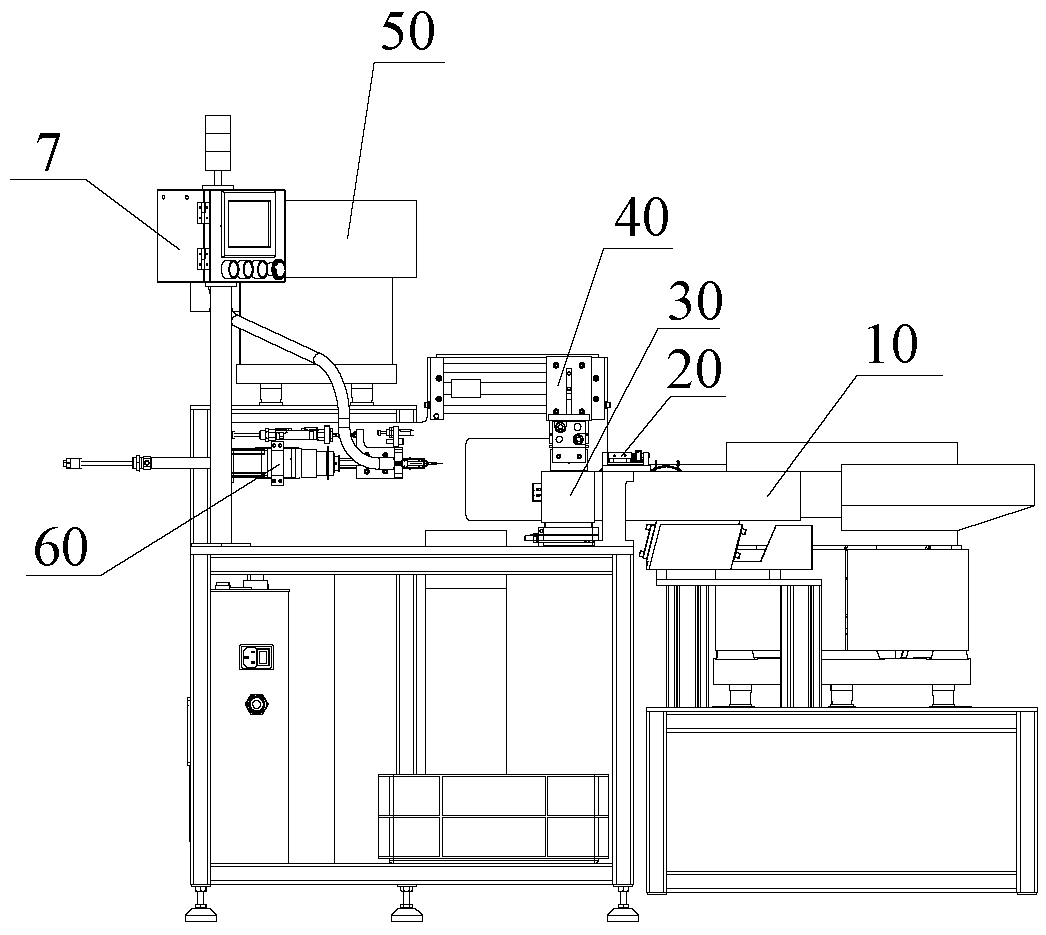

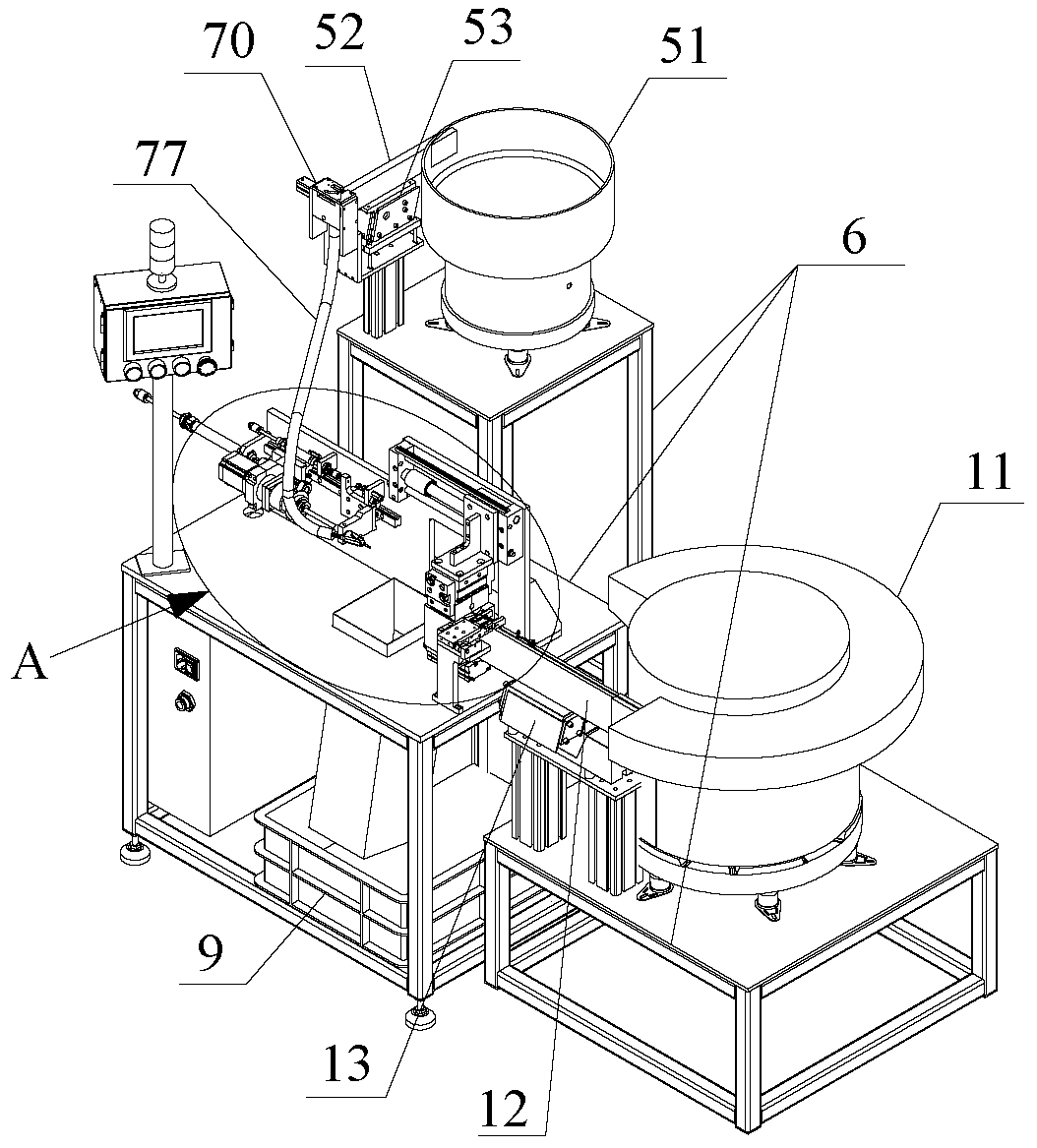

[0043] See Figure 2 to Figure 10 , a clamp lock screw machine for washing machine inlet and drain pipes of the present invention, which includes a frame 6, a controller 7 is installed on the frame 6, and a clamp main body feeding mechanism 10 and lugs are respectively electrically connected to the controller 7 Recognition mechanism 20, reversing mechanism 30, clip main body clamping mechanism 40, screw feeding mechanism 50 and locking screw mechanism 60; clip main body feeding mechanism 10 is used to arrange the clip main body 1 so that the clip main body 1 is arranged side by side continuously Front conveying, and the lugs on the clamp main body 1 are all located on the same straight line during conveying; the lug identification mechanism 20 is set at the outlet end of the clamp main body feeding mechanism 10 for identifying the outlet of the clamp main body feeding mechanism 10 whether the lug 4 of the clamp body 1 at the end is in the front; the reversing mechanism 30 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com