Track maintenance device for road detection

A maintenance device and road detection technology, which is applied to roads, tracks, ballast layers, etc., can solve problems such as slow return speed, low work efficiency, and poor vibration reduction effect, so as to simplify manual mechanical operations and improve work efficiency , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

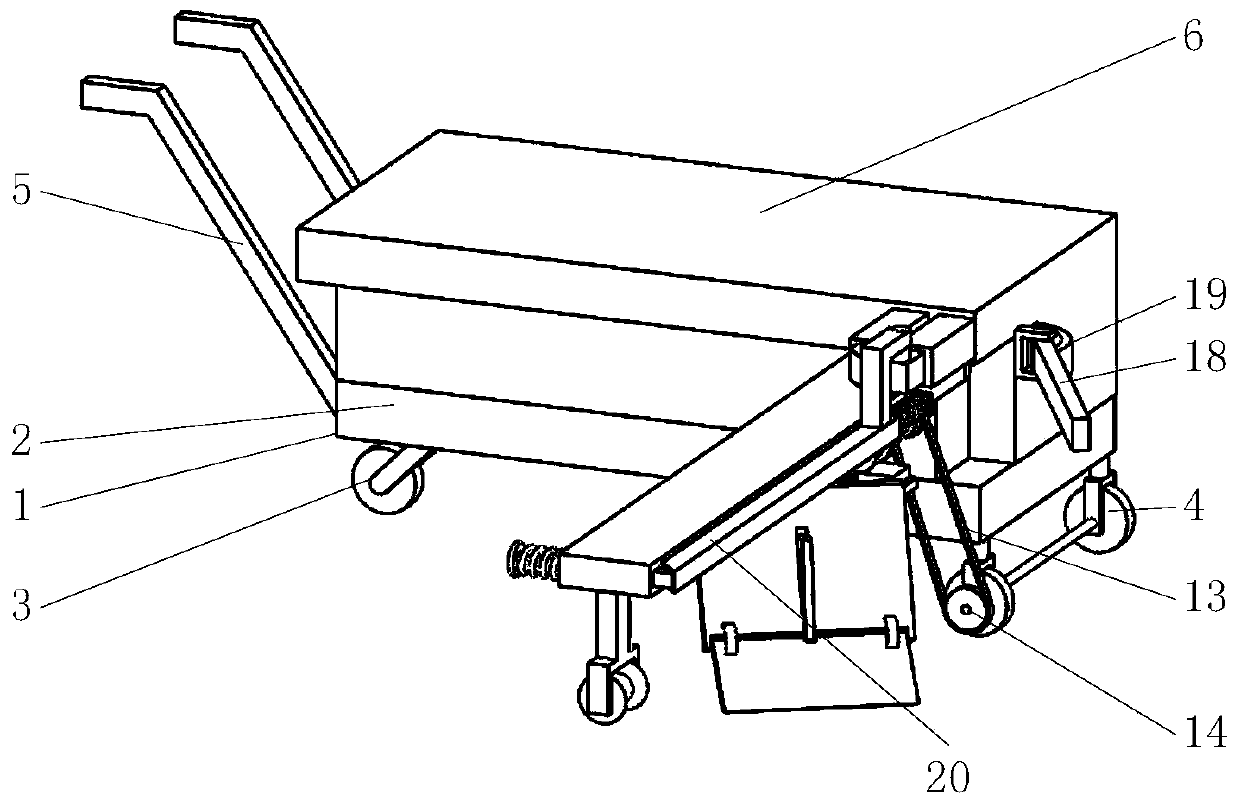

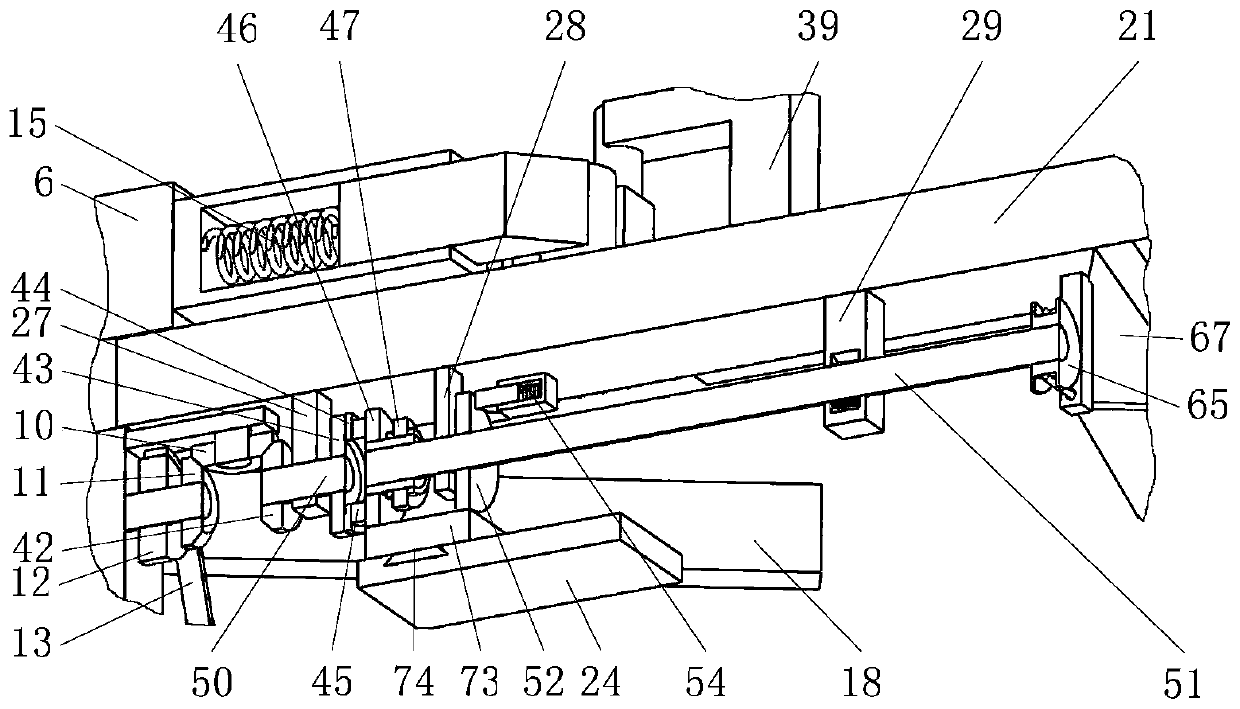

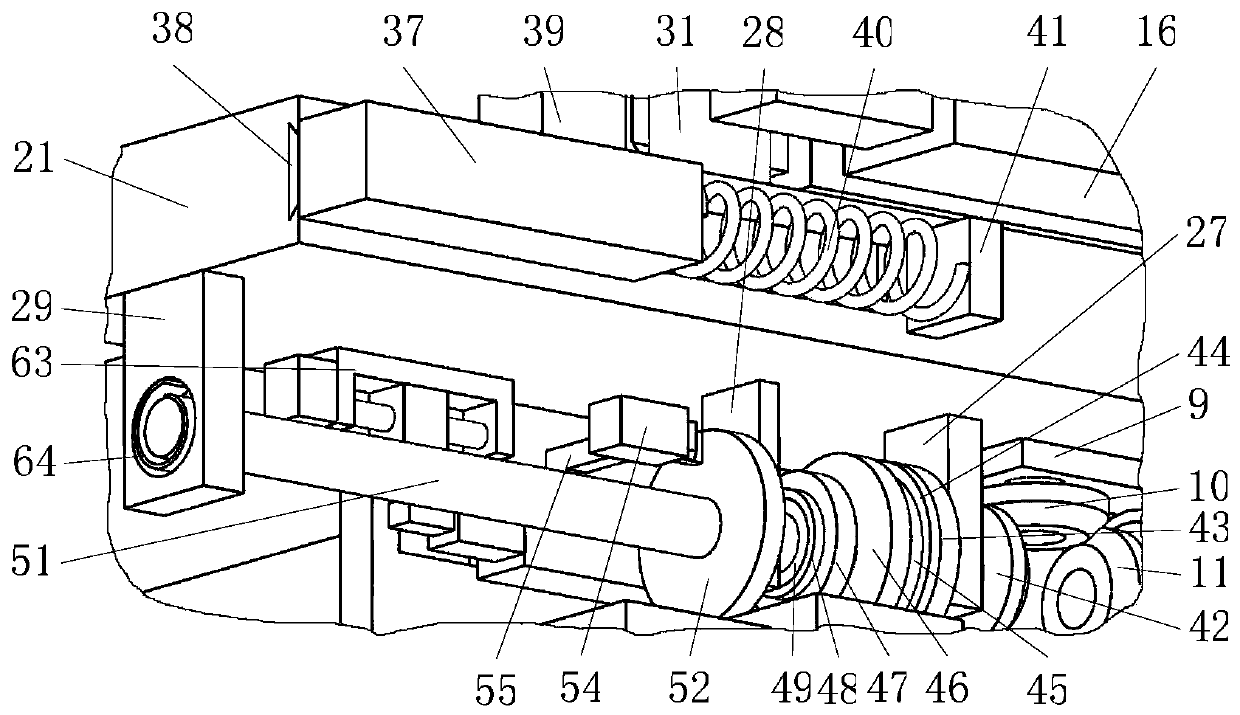

[0037] Such as figure 1 , 2 As shown, it includes a diesel power module, an expansion plate A15, an expansion plate B16, and a folding mechanism 20 housed in the upper casing 6 of the car body 1, wherein as figure 1 As shown, the folding mechanism 20 is hinged to the side front end of the housing 6 and swings horizontally around its hinge point; Figure 4 , 15 As shown, the telescopic plate A15 and the telescopic plate B16 with inclined planes at the end of the inner plate are distributed horizontally at the front end of the side of the housing 6, and the telescopic plate B16 is located in front of the telescopic plate A15; figure 2 , 4 As shown, the inner plate of the teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com