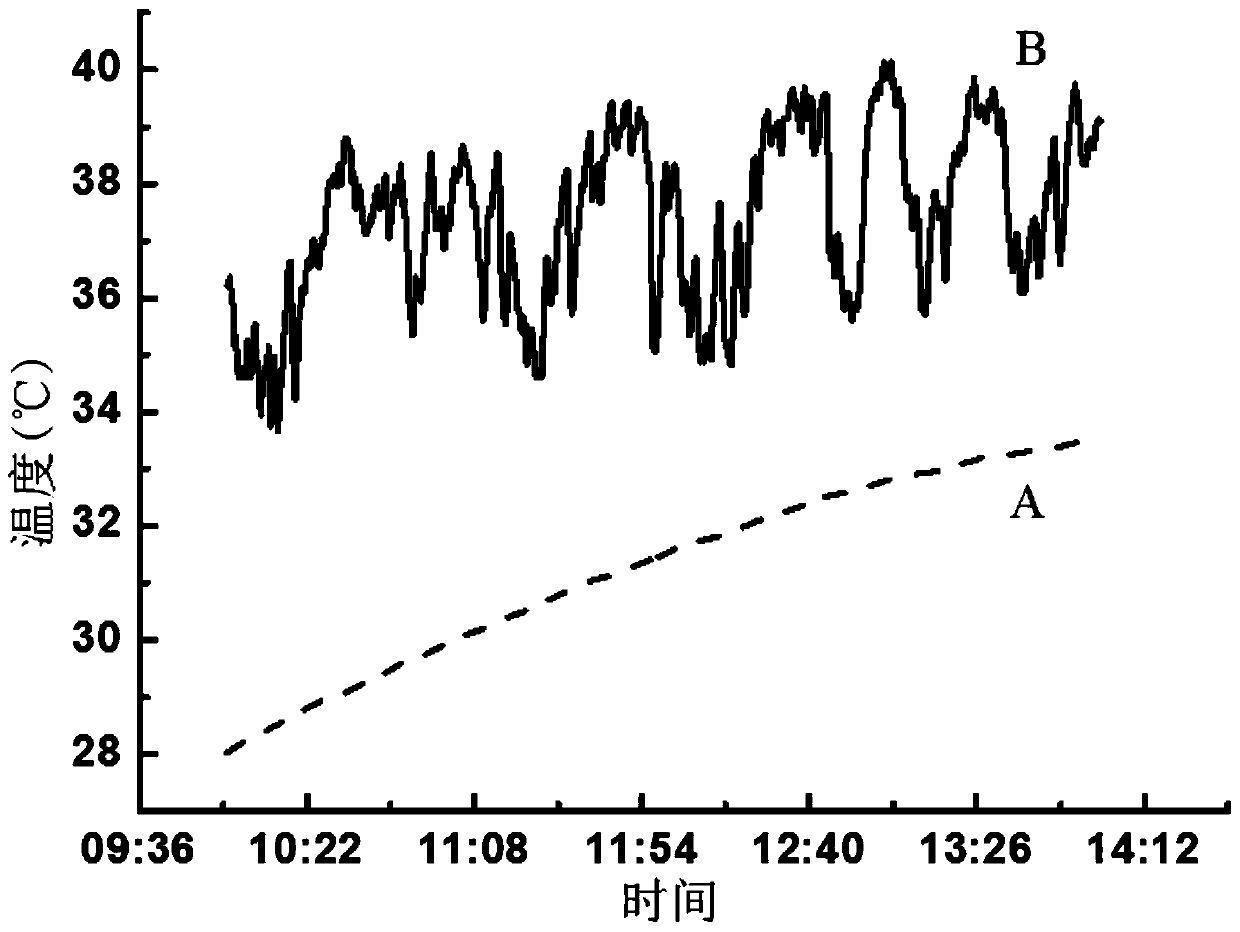

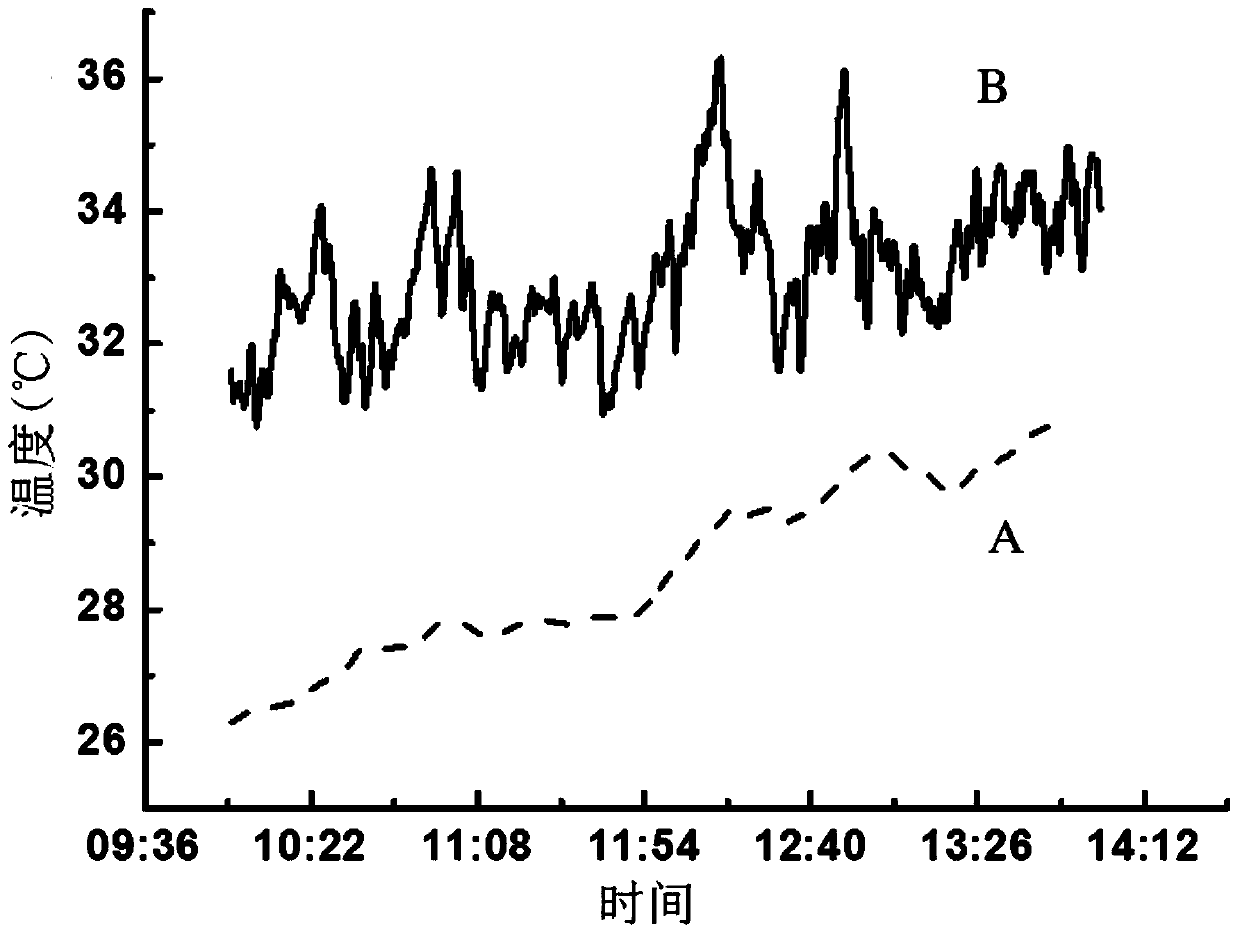

Light green refrigeration coating with temperature lower than ambient temperature under direct sunlight

A technology for surrounding environment and direct sunlight, applied in reflective/signal coatings, coatings, primers, etc., can solve problems such as light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Specific Embodiment 1: This embodiment is a kind of light green refrigeration coating that is lower than the surrounding ambient temperature under direct sunlight. It is composed of a white primer and a light green topcoat. The solar reflectance of the white primer is 0.9, and the sunlight The effective solar reflectance of the light green cooling coating lower than the ambient temperature under direct sunlight is ≥0.935.

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the white base paint is ≥250 μm, and the thickness of the light green top paint is 50 μm˜100 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the white primer is composed of styrene-acrylic emulsion, titanium dioxide, talcum powder, far-infrared ceramic powder, water and additives, and The mass fraction of styrene-acrylic emulsion in the white primer is 44%, the mass fraction of titanium dioxide is 30%, the mass fraction of talcum powder is 8%, the mass fraction of far-infrared ceramic powder is 6%, and the mass fraction of water is 10%. , the mass fraction of additives is 2%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com