Energy recovery device of drawing furnace

A technology of energy recovery and drawing furnace, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as energy waste, achieve the effects of solving light pollution, improving cooling effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

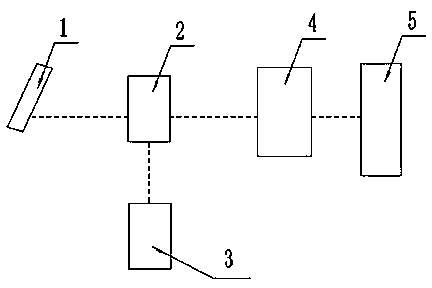

[0028] like figure 1 As shown, a drawing furnace energy recovery device of the present invention includes: photovoltaic backplane 1, charge and discharge controller 2, battery pack 3, inverter 4 and AC power distribution cabinet 5, photovoltaic backplane 1 and charge and discharge controller 2, the charging and discharging controller 2 is connected with the inverter 4, the inverter 4 is connected with the AC power distribution cabinet 5, and the charging and discharging controller 2 is connected with the battery pack 3.

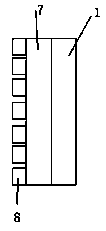

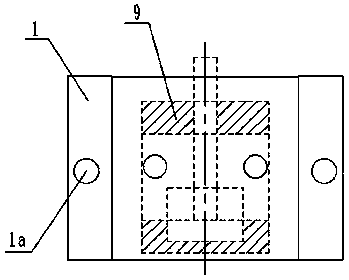

[0029] On the basis of the above, the present invention also includes a trolley 6, a heat conduction plate 7, and a flow channel 8. The photovoltaic backplane 1 is N≥3 pieces, forming a closed chamber around and surrounding the wire drawing furnace 9. The photovoltaic backplane 1 and the wire drawing furnace 9, a certain gap is left, and the photovol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com