Digital television cathode ray tube screen display dead pixel detection method

A cathode ray tube and digital TV technology, which is applied in TV, electrical components, image communication, etc., can solve the problems of not providing detection of concave spots outside the screen, single detection method of screen dead spots, and failure to find black spots, etc., to achieve increased The effect of the range of use, convenience for pixel failure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

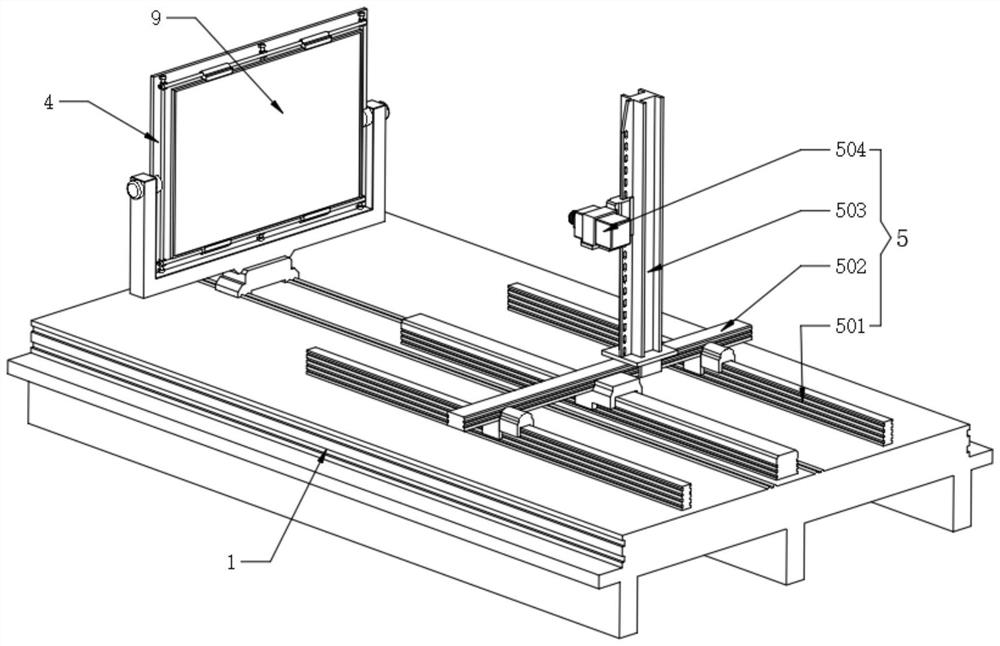

[0059] Refer to attached Figure 4 , the screen holder 4 also includes a base 401, the top of the base 401 is rotatably mounted with a back plate 402, the side wall of the back plate 402 close to the pixel defect detection assembly 5 is equidistantly fixed with guide rods 403, the side wall of the back plate 402 A clamping bar 404 is movable, and a sliding assembly connection is formed between the two clamping bars 404 and the guide bar 403, and the outer surfaces of the two clamping bars 404 are fixedly provided with a clamping block 405 for clamping the display screen body 9, the clamping bar Both ends of 404 are screwed with fixing screws 406, and the display screen body 9 to be tested is fixedly assembled on one side of the backboard 402, and the upper and lower clamping rods 404 are moved, and the clamping block 405 is clamped to the display screen body 9 The upper and lower sides of the upper and lower sides, after determining the position, tighten the fixing screw 406 t...

Embodiment 2

[0065] Refer to attached Figure 5 , the light-emitting assembly 6 also includes a bottom rail two 601, which is fixedly installed on one side of the upper surface of the detection table 1, and the upper surface of the bottom rail two 601 is slidably assembled with an illuminator shell 602, and the illuminator shell 602 can be mounted along the bottom rail Moving in the direction of 601, the inside of the illuminator housing 602 is equidistantly fixed with the inner lamp tube 603, and the side of the illuminator housing 602 close to the outer screen dead point detection component 7 is fixedly provided with a light-transmitting cover 604.

[0066] Refer to attached Figure 5 , the outer screen dead point detection component 7 also includes a lifting rail frame two 701, the lifting rail frame two 701 is fixedly installed on the other side of the upper surface of the detection table 1, and one side of the outer wall of the lifting rail frame two 701 is slidingly assembled with a ...

Embodiment 3

[0070] Refer to attached Image 6 , the laser assembly 8 also includes a rotating motor 2 801, the output end of the rotating motor 2 801 is fixedly connected with a mounting frame 802, the inner side of the mounting frame 802 is rotatably mounted with a laser 803, and one side of the outer wall of the mounting frame 802 is fixedly mounted with a rotating motor 3 804 , and the output shaft of the rotating motor 3 804 is fixedly connected to the laser 803. After the imaging brightness meter 704 finds the black spot on the outer screen, according to the coordinates of the black spot, the rotating motor 2 801 and the rotating motor 3 804 work to make the laser 803 face the black spot. The position of the dot, followed by a laser, indicates the position of the black dot.

[0071] The working principle of the present invention is: after the imaging brightness meter 704 finds the black spot on the outer screen, according to the coordinates of the black spot, the rotating motor 2 801...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com