Multiple-impact loading test device

A loading test device and guide rail technology, which is applied in the field of explosive performance parameter experiments, can solve the problems of inability to accurately simulate the force of explosives, fail to meet research needs, and fail to simulate multiple loadings with large drop hammers, so as to fill the gap in China Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

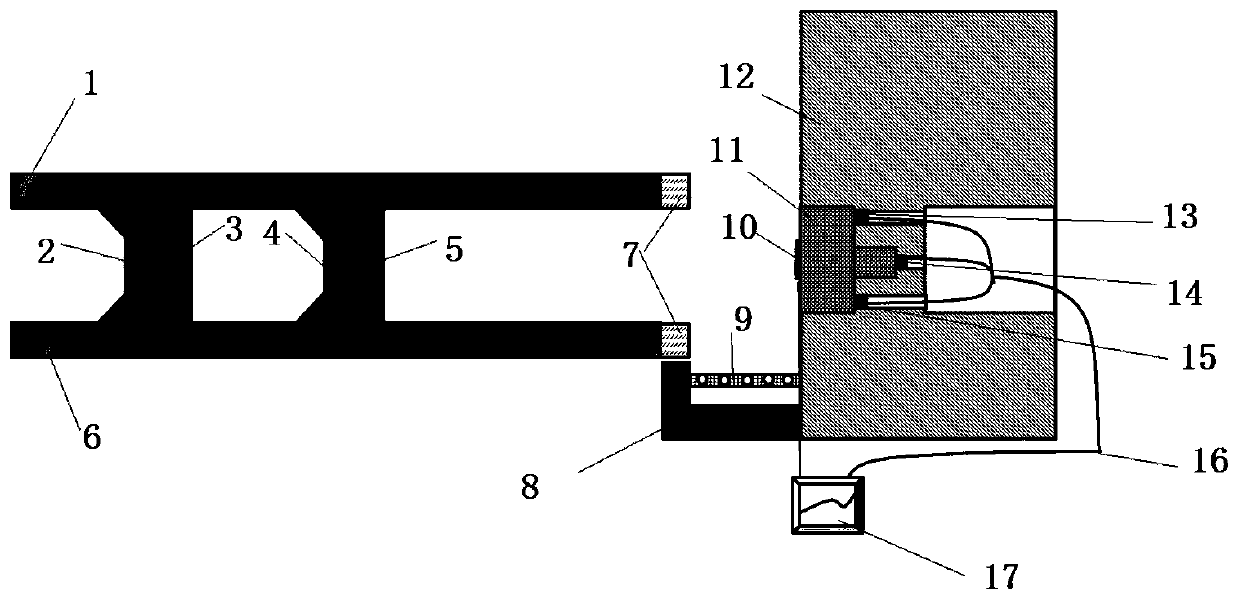

[0020] In this embodiment, a multi-impact loading test device is designed, and the B explosive is subjected to two impact ignition tests, the time between the impact of the two projectiles is 200ms, and the impact velocity of the projectile is 100m / s.

[0021] A multiple impact loading test device, characterized in that: the device comprises guide rail negative 1, armature A2, projectile A3, armature B4, projectile B5, guide rail positive 6, laser speedometer 7, electromagnet 8, and block 9 , Strain gauge 10, sample 11, base 12, temperature sensor A13, pressure sensor B14, particle velocity sensor C15, data line 16 and controller 17, the guide rail negative 1 and guide rail positive 6 are made of conductive metal, the guide rail The length of the negative electrode 1 and the positive electrode 6 of the guide rail is 6 to 10 times the distance between the two, which can ensure that the projectile A3 and the projectile B5 obtain the best ejection speed. The projectile A3 and the pro...

Embodiment 2

[0028] In this embodiment, a multiple impact loading test device is designed to perform two impact ignition tests on the passivated RDX explosive, the time between two projectiles impact is 10ms, and the projectile impact velocity is 180m / s.

[0029] A multi-impact loading test device, characterized in that the device includes guide rail negative 1, armature A2, projectile A3, armature B4, projectile B5, guide rail positive 6, laser speedometer 7, electromagnet 8, and block 9 , Strain gauge 10, sample 11, base 12, pressure sensor A13, pressure sensor B14, pressure sensor C15, data line 16 and controller 17, the rail negative 1 and rail positive 6 are made of conductive metal, and the rail negative The length of 1 and the positive electrode 6 of the guide rail is 6 to 10 times the distance between the two, which can ensure that the projectile A3 and projectile B5 obtain the best exit speed. The projectile A3 and projectile B5 are steel cylinders, the armature A2, The projectile A3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com