Control method and controller for statcom output current at the end of torsional vibration machine

A technology of output current and control method, which is applied in the field of machine-end STATCOM output current control method and controller for suppressing torsional vibration, can solve problems such as poor torsional vibration effect, achieve the goal of alleviating torsional vibration, reducing power grid disturbance, and improving the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

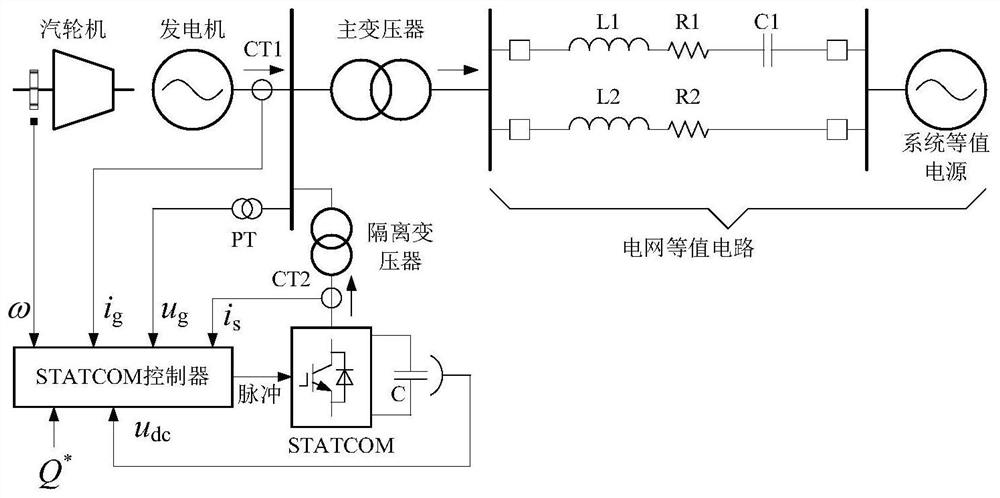

[0070] like figure 1 Shown is the wiring diagram of the electrical equipment in the present invention. The STATCOM primary equipment is connected to the generator terminal bus through an isolation transformer, and the STATCOM controller is connected to the steam turbine generator set speed ω and generator terminal voltage u g , generator terminal current i g , STATCOM output current i s , STATCOM DC side voltage u dc and other signals; at the same time, the STATCOM controller also receives the external reactive power command Q * . In the figure, CT1 is the machine-end current transformer, PT is the machine-end voltage transformer, and CT2 is the STATCOM output current transformer. The grid system is equivalent to a two-circuit and infinite power system, one of which has capacitor series compensation, and the other The return line has no capacitor series compensation.

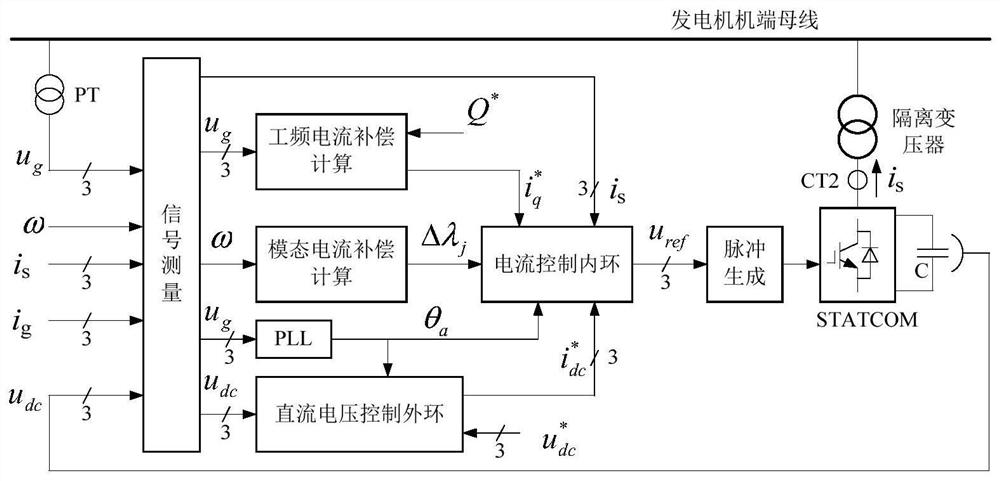

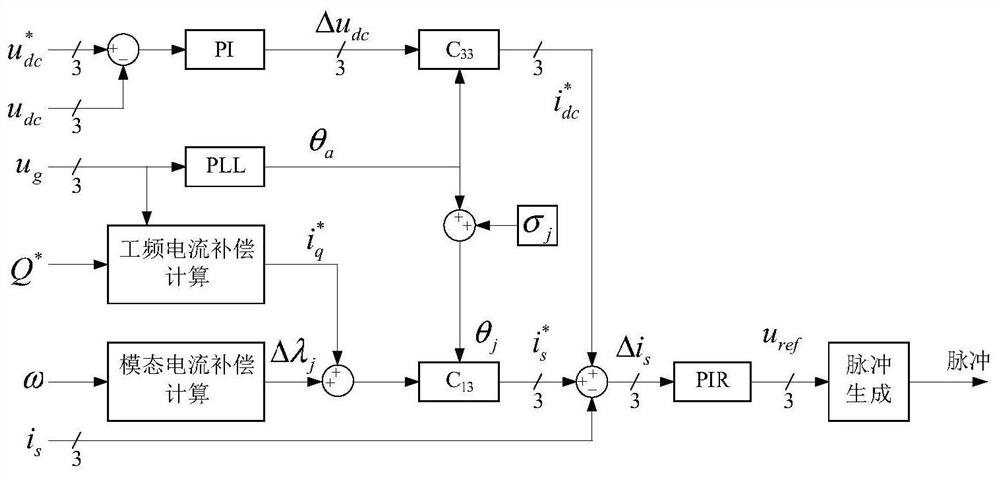

[0071] figure 2 Shown is a schematic diagram of the relationship between external signal acquisition a...

Embodiment 2

[0096] The wiring of electrical equipment in the method of the present invention is as follows: figure 1 As shown, the STATCOM primary equipment is connected to the generator terminal bus through an isolation transformer, and the STATCOM controller is connected to the turbo-generator set speed ω, generator terminal voltage u g , generator terminal current i g , STATCOM output current i s , STATCOM DC side voltage u dc and other signals; at the same time, the STATCOM controller also receives the external reactive power command Q * . In the figure, CT1 is the machine-end current transformer, PT is the machine-end voltage transformer, and CT2 is the STATCOM output current transformer. The grid system is equivalent to a two-circuit and infinite power system, one of which has capacitor series compensation, and the other The return line has no capacitor series compensation.

[0097] In this embodiment, the rated capacity of the generator is 667MVA, the rated voltage is 20kV, th...

Embodiment 3

[0129] Image 6 Shown is a schematic diagram of the relationship between external signal acquisition and internal calculation modules of the controller of the present invention. A specific embodiment of a machine-side STATCOM controller for suppressing torsional vibration of the present invention includes a power frequency current compensation calculation module and a current control inner loop module, and the power frequency current compensation calculation module calculates according to a given reference value of reactive power The power frequency current compensation value is obtained, and the power frequency current compensation value is input to the current control inner loop module to participate in the calculation of the modulated wave voltage reference value.

[0130] The above controller also includes a signal quantity measurement module, a modal current compensation calculation module, a DC voltage control outer loop module, and a pulse generation module; the power f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com