Laser surface processing equipment

A laser surface treatment and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the unsatisfactory problems of laser surface treatment equipment, shorten the overall processing time, improve the effect, reduce laser The effect of the surface preparation step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

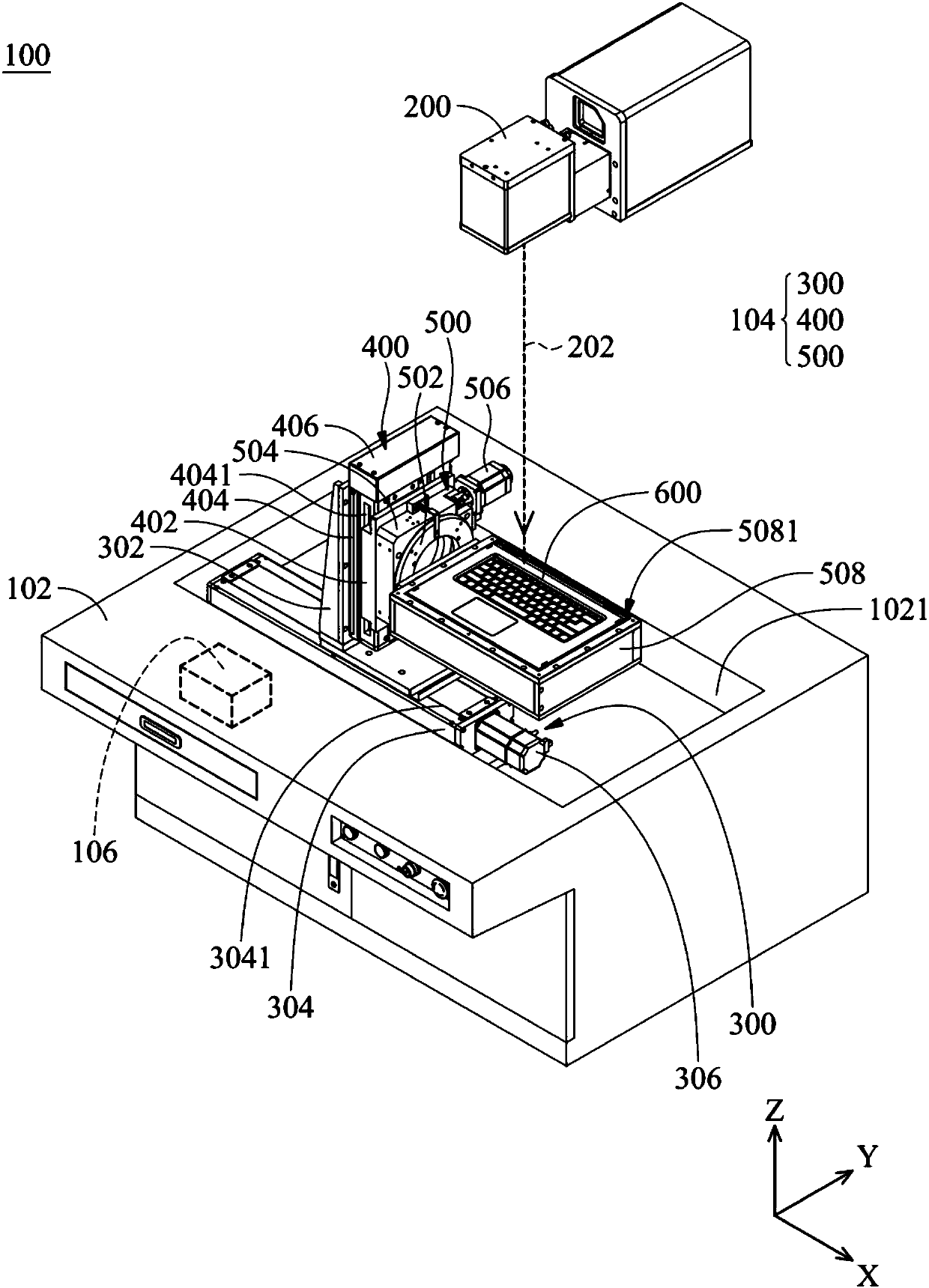

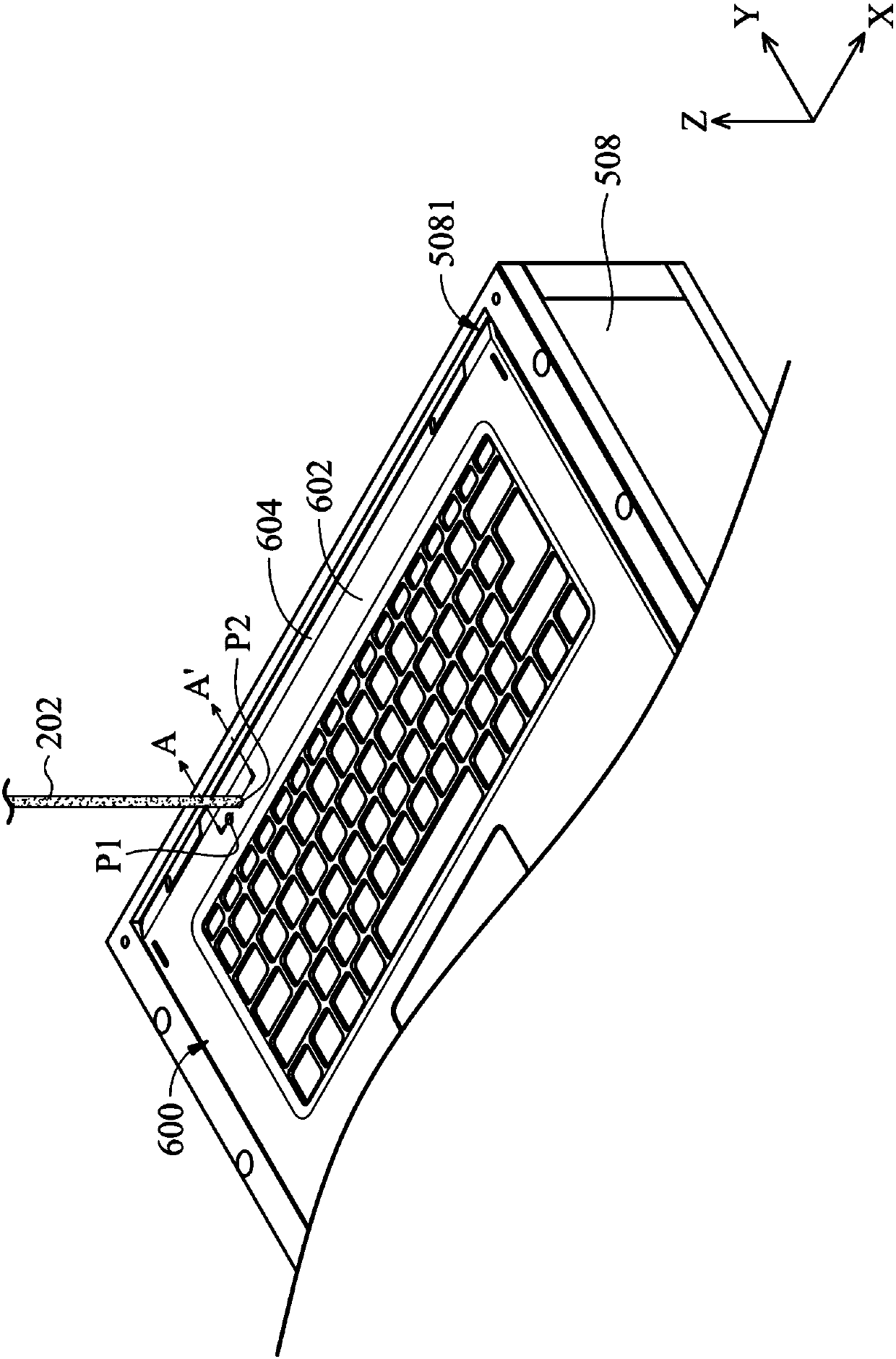

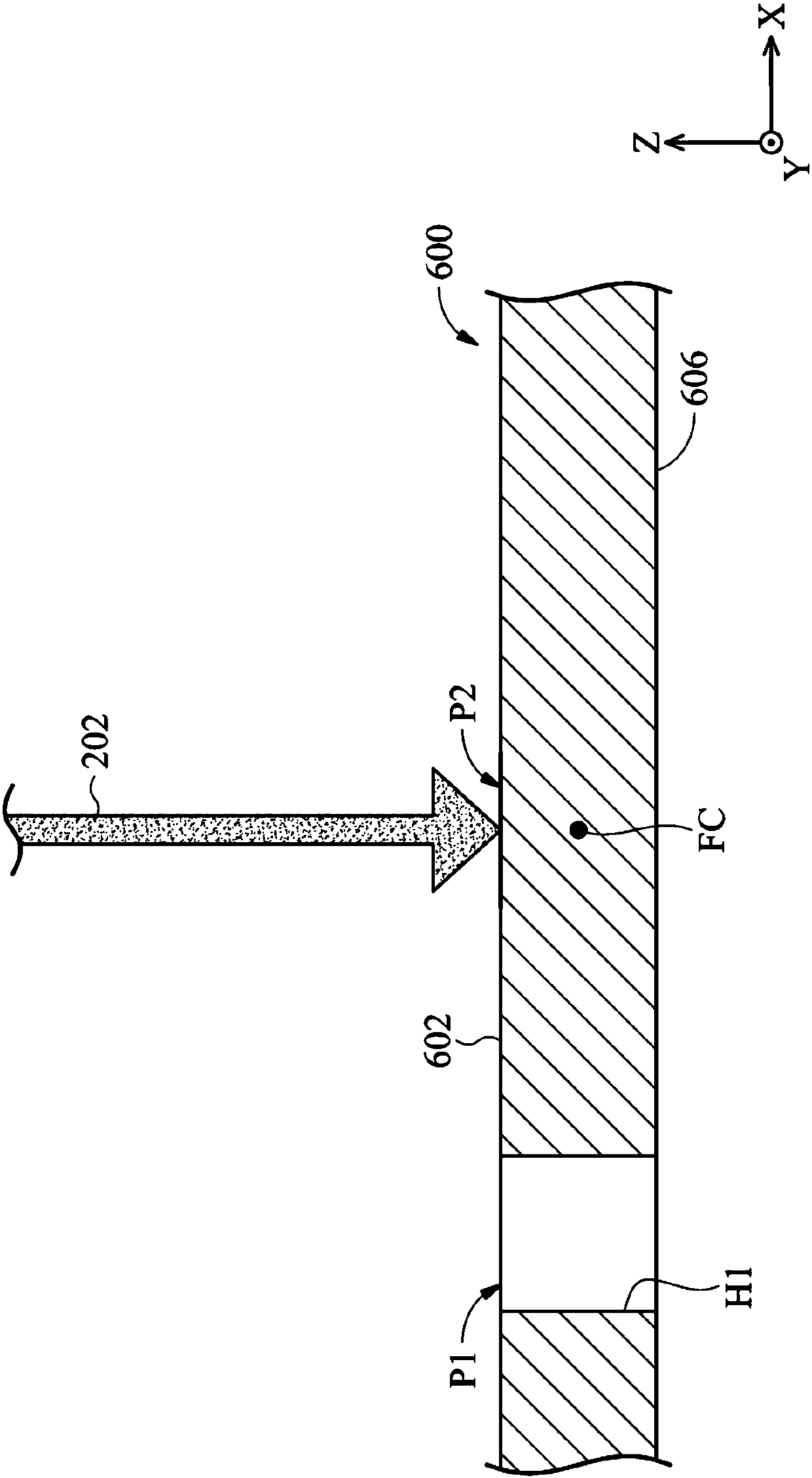

[0095] In order to make the purpose, features, and advantages of the present disclosure more comprehensible, the following specific embodiments are described in detail with accompanying drawings. Wherein, the configuration of each component in the embodiment is for illustration, not for limiting the present disclosure. In addition, part of the symbols in the figures in the embodiments are repeated for the purpose of simplifying the description, and do not imply the relationship between different embodiments. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms used are for illustration and not for limitation of the present disclosure.

[0096] In addition, relative terms such as "lower" or "bottom" and "higher" or "top" may be used in the embodiments to describe the relative relationship of one component to another component in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com