Knotting mechanism for strapping machine and knotting method

A technology of strapping machine and olecranon, which is applied to the parts of strapping machinery and other directions, can solve the problems of the olecranon opening and the olecranon not returning to the correct position completely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

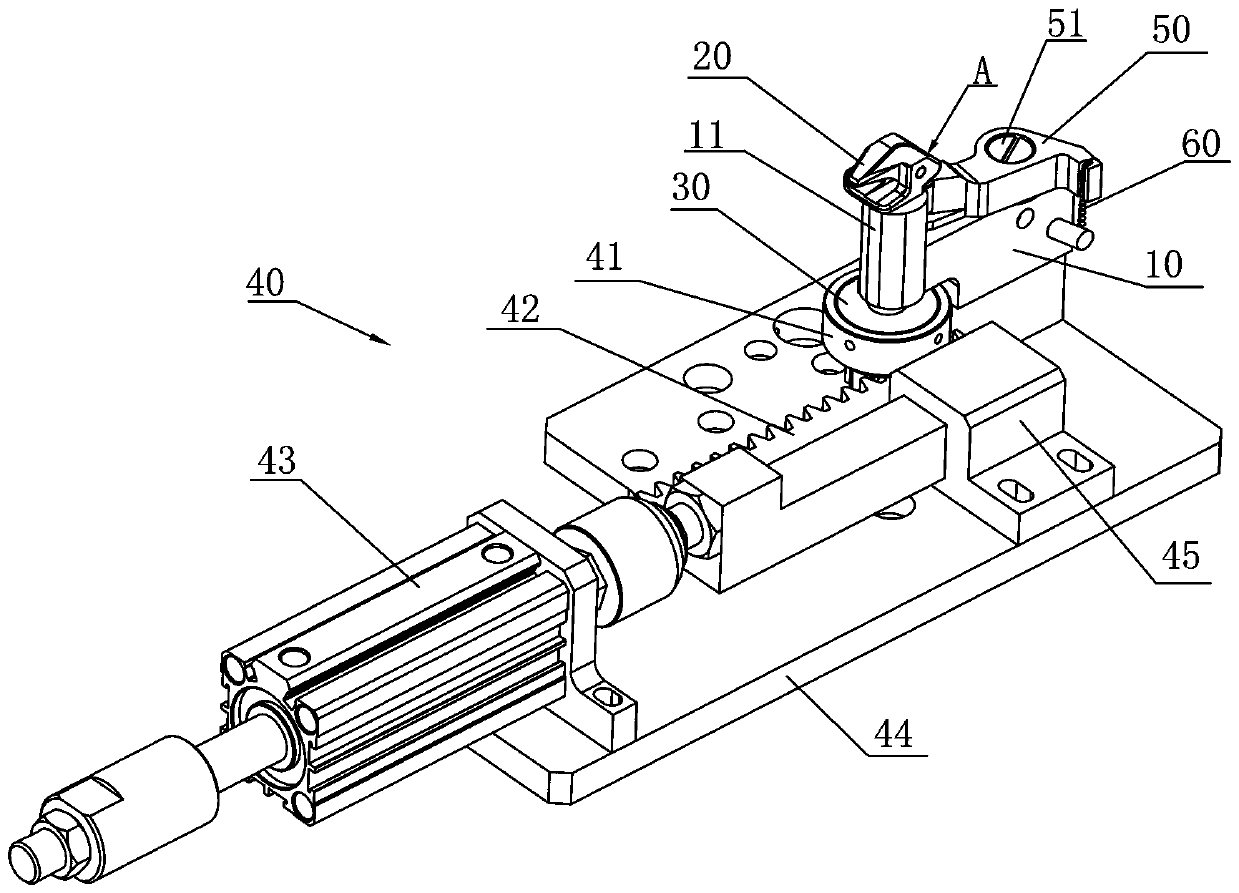

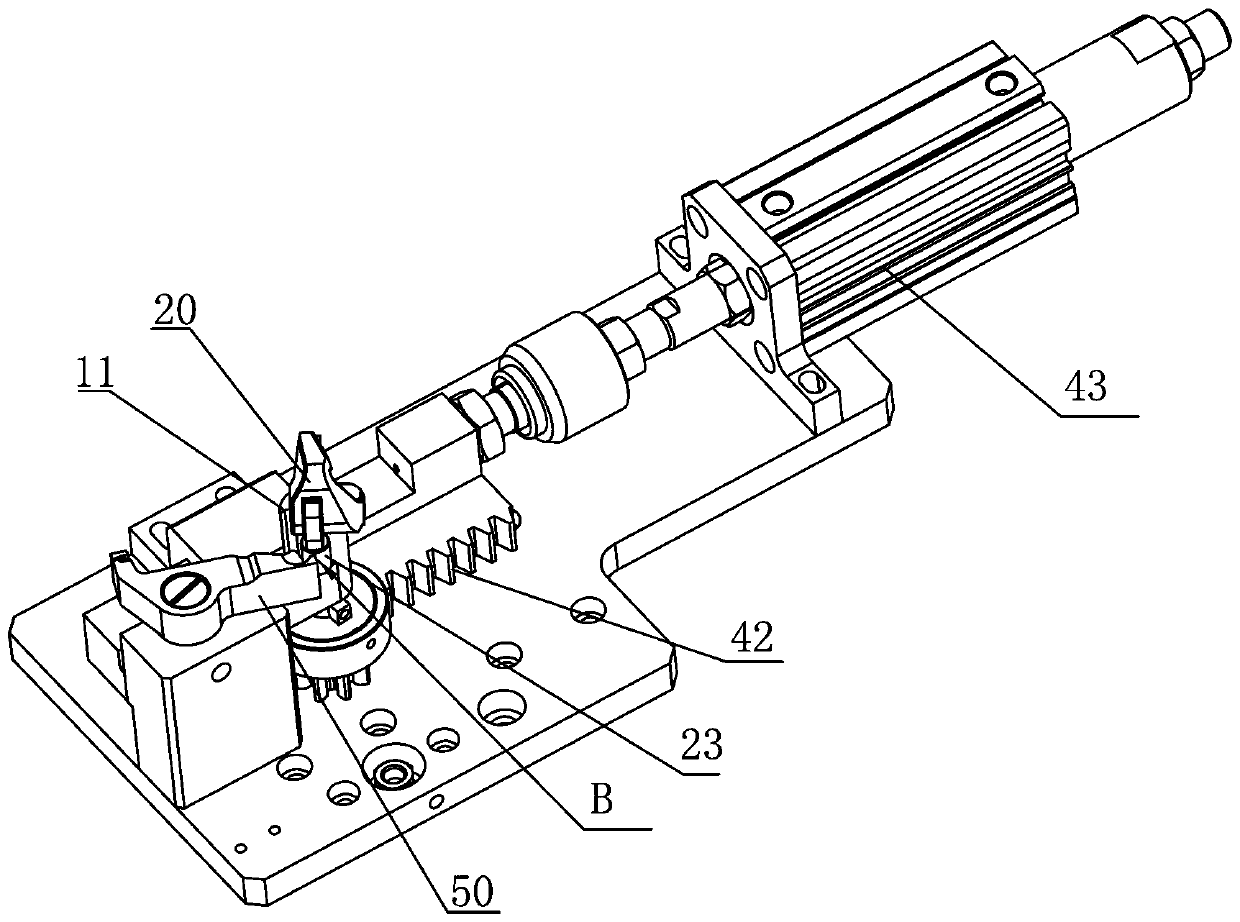

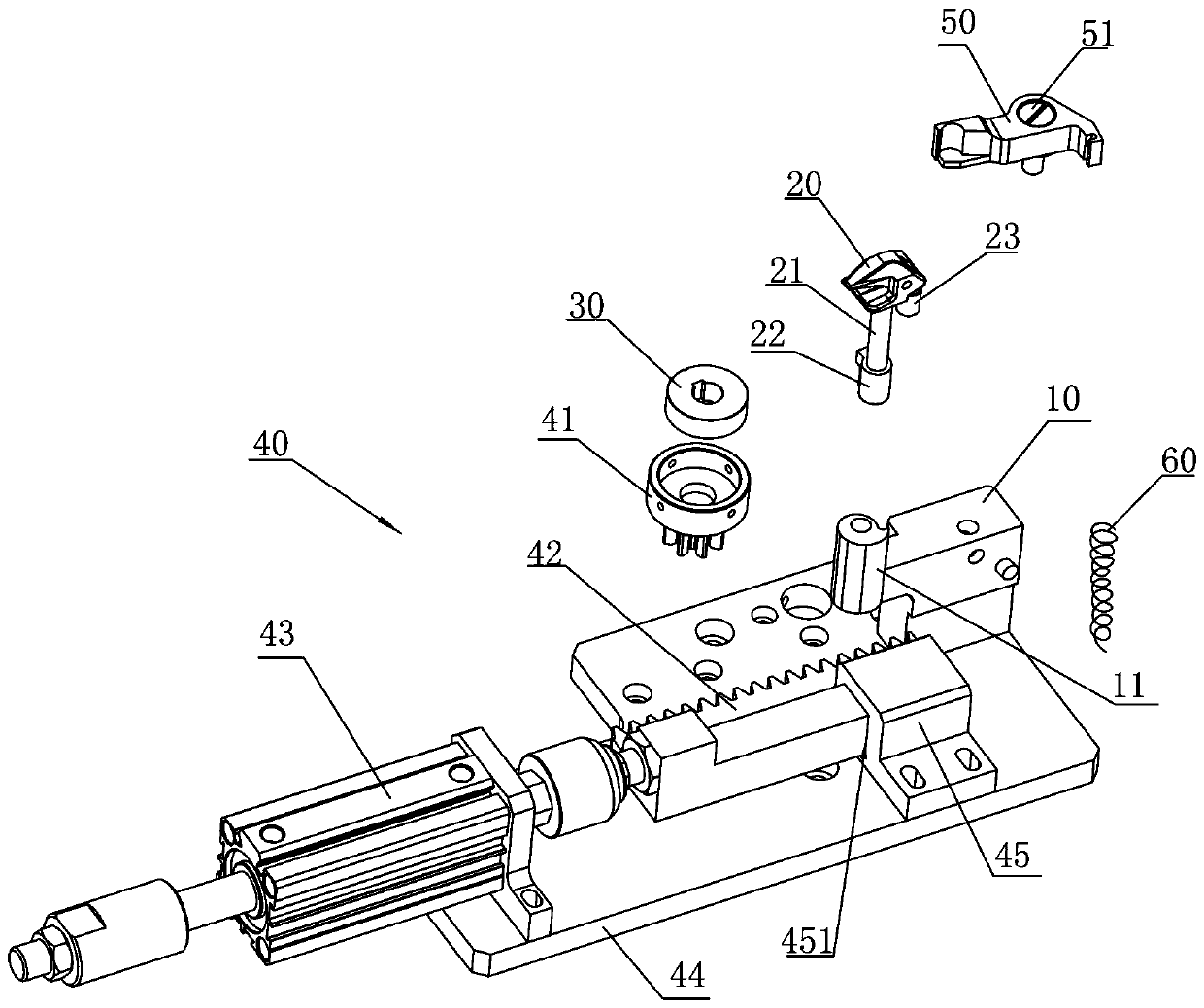

[0023] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

[0024] Figure 1 to Figure 5 , which is a preferred embodiment of a knotting mechanism for a strapping machine provided by the present invention. Such as Figure 1 to Figure 5 As shown, the knotting mechanism for the strapping machine includes a fixed seat 10, one end of the fixed seat is provided with a cam-shaped cylinder 11, and the cam-shaped cylinder 11 is provided with a rotatable olecranon 20 for knotting. The rotating shaft 21 of the olecranon passes through the fixed seat and is connected with a one-way bearing 30 through a connecting pin 22. The tail of the olecranon is provided with a positioning sliding sleeve 23 for rotating around a cam-shaped cylinder to drive the olecranon to open and close when the olecranon rotates. The bottom of the fixed seat 10 is provided with a drive assembly 40 that cooperates with the one-way bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com