Etching solution for etching metal layer composed of copper layer and molybdenum layer and application thereof

An etching solution and organic acid technology, applied in the field of etching solution for metal layers, can solve the problems of poor control of etching uniformity, uneven etching surface, increased environmental load, etc., and achieve uniform etching without residue, environmental friendliness, and etching speed. proper effect

Active Publication Date: 2021-08-24

江苏和达电子科技有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, inorganic acids such as nitric acid, sulfuric acid, phosphoric acid, and fluoride are mostly used in etching solutions for etching molybdenum-containing metal layers. The etching rate is fast but the etching uniformity is not easy to control.

For example, the Chinese patent with the publication number CN102392248B discloses a molybdenum and / or aluminum metal film etching solution for OLEDs and a preparation method thereof. The etching solution uses nitric acid aqueous solution, phosphoric acid aqueous solution, betaine amphoteric surfactant and water as main components. , and Taiwan Patent Application Publication No. TW201137176A discloses an etchant for a multilayer thin film with a copper layer and a molybdenum layer. The etchant uses substances including hydrogen peroxide and inorganic acid nitric acid. These two patents disclose Due to the use of strong acidic components in the etching solution, the etching rate is faster. When etching finer wires, the line width will not be narrow enough and the etching surface will be uneven.

Another example is that the Taiwan patent with the publication number TWI231275B discloses a multilayer etching solution of copper and molybdenum, including hydrogen peroxide, organic acid, phosphate, fluoride, nitrogen-containing additives, etc. However, high concentrations of nitrogen-containing additives and Fluoride ions increase environmental load

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

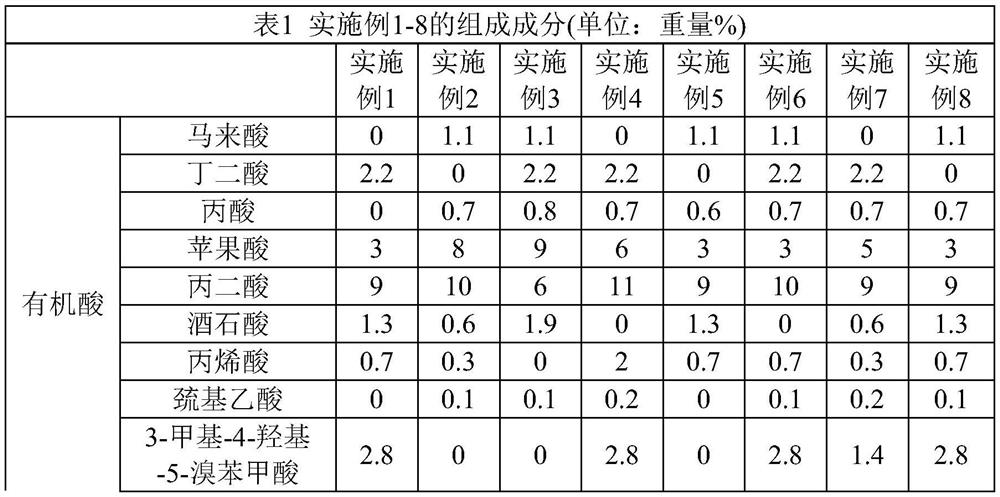

Embodiment 1-8

[0040]

[0041]

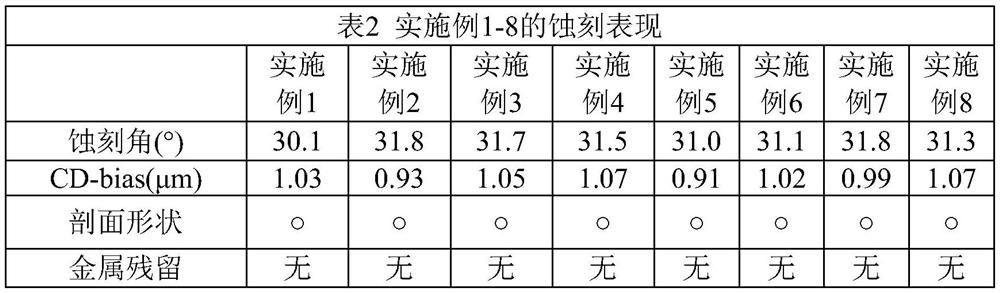

[0042] The etching performance of embodiment 1-8 is as shown in table 2:

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an etching solution and its application in etching a metal layer composed of a copper layer and a molybdenum layer. The etching solution comprises: an organic acid containing 3 or more carbon atoms; an organic base; hydrogen peroxide; stabilizers; and deionized water. The etching solution provided by the invention has the effects of appropriate etching rate, easy control of etching direction, uniform etching and no residue on the metal layer composed of copper layer and molybdenum layer, and the etching solution has high stability, is environmentally friendly, and has good application value.

Description

technical field [0001] The invention belongs to the field of metal surface chemical treatment, in particular to an etching solution for etching a metal layer composed of a copper layer and a molybdenum layer and an application thereof. Background technique [0002] A liquid crystal display (LCD) usually includes upper and lower substrates and a liquid crystal medium clamped therein. The substrate is usually provided with a metal layer containing copper and other low resistivity and high corrosion resistance. The metal layer of the display is mostly made of aluminum, copper, Titanium, iron and other metals or metal oxides, the process is more complicated. Due to the characteristics of the material, some of them can no longer meet the quality requirements of the current market, and the resistance of the metal wire is large, which will cause signal delay. If the number of screen swipes is less than 24 times per second, you will see tailing or freezing. Therefore, it is more co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23F1/44C23F1/18C23F1/26

CPCC23F1/18C23F1/26C23F1/44

Inventor 王毅明邵振

Owner 江苏和达电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com