Scheme for increasing torsion through peening driving of rotary type soft handle elastic peening hammer in vacuum cover

A hammer and vacuum cover technology, applied to transmission boxes, transmission devices, components with teeth, etc., can solve problems such as torque lifting of difficult mechanical shafts

Inactive Publication Date: 2019-09-10

王江荣

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is difficult to increase the torque of the mechanical shaft during the transmission process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

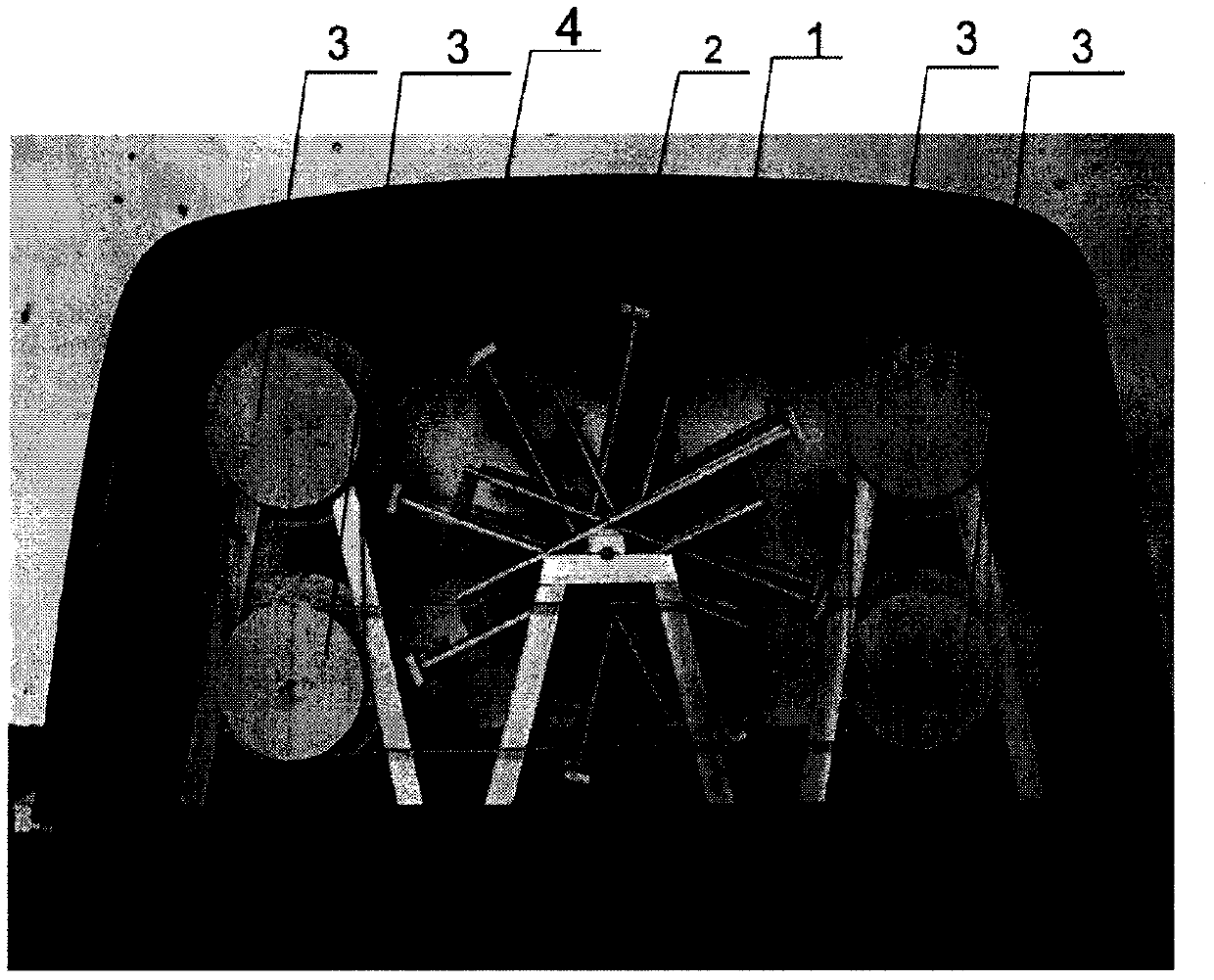

[0017] With reference to the accompanying drawings, step-by-step start (1) rotary soft handle elastic hammer turntable is struck by (2) elastic percussion hammer (3) elastic percussion device torsion rotating disk is installed outside the circumference, and several rotating disks are connected to strengthen the torsion.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

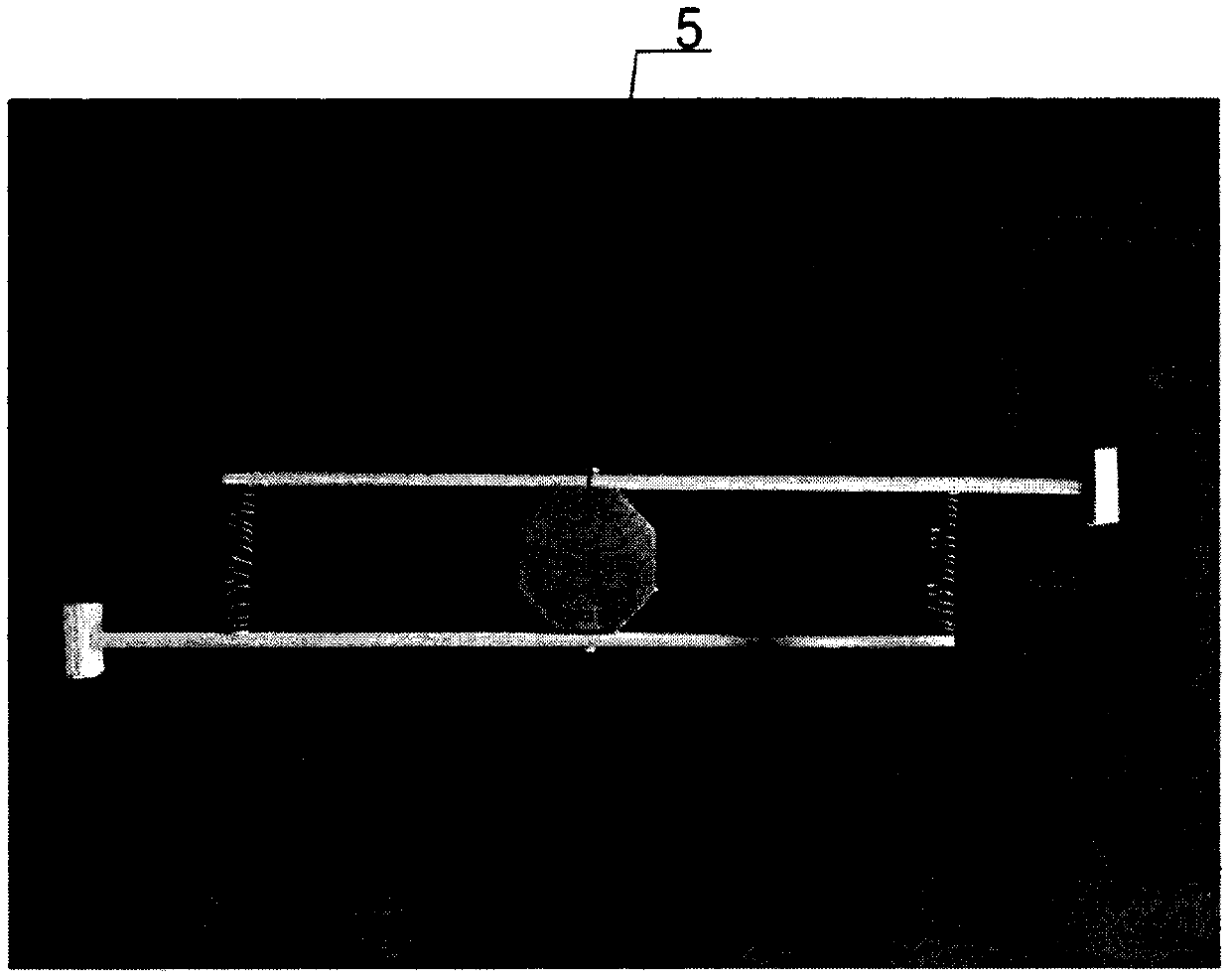

The invention provides a scheme, and discloses a scheme for increasing torsion through peening driving of a rotary type soft handle elastic peening hammer in a vacuum cover. The scheme is characterized in that an energy starting machine (comprising an electric motor) is connected with a soft handle elastic peening hammer turntable by means of a mechanical rotating shaft, a plurality of elastic device torque rotating discs are synchronously densely peened by the peening hammer, and torque shafts of the elastic device torque rotating discs are connected to act synchronously. The torque shafts ofthe rotating discs are connected with an electric generator to generate a power supply, air in the vacuum cover is pumped completely to reduce the resistance in operation, and the machine rotates under the condition of no resistance in acting, so that the torque is increased. The application of the scheme is to convert mechanical energy into electrical energy and take a part of electrical energyas clean energy without the need of resources and energy, and the scheme is a development direction of new energy creation.

Description

[0001] Technical field: [0002] The proposal of the present invention is to change the existing transmission mode, to rotate a flexible hammer with a soft handle in the vacuum cover, and to enhance the torsion force in the strike transmission. [0003] technical background: [0004] Existing motors and mechanical transmission modes are: shafts, gears, chains, belts, and synchronous belts. It is difficult to increase the torque of the mechanical shaft during the transmission process. [0005] Invention content: [0006] The solution of the present invention is to change a transmission mode, aiming at the bottleneck of the prior art, it is difficult to increase the torque during the mechanical transmission process. Design a soft-handled elastic hammer that rotates in the vacuum cover, and the scheme of strengthening the torque of the impact transmission. It is characterized in that the elastic percussion hammer has a soft handle with a large circumference and a long soft hand...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H31/00F16H57/02

CPCF16H31/00F16H57/02

Inventor 王江荣

Owner 王江荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com