Parallel groove wire clamp

A wire clip and clip body technology, applied in the direction of electrical components, circuits, connections, etc., can solve the problems of not being able to effectively adapt to different specifications of twisted wires, unstable clamping, etc., and achieve easy disassembly, easy protection, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

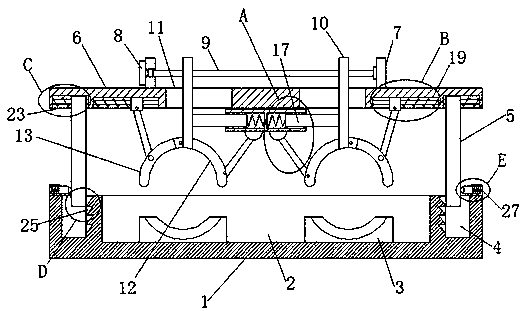

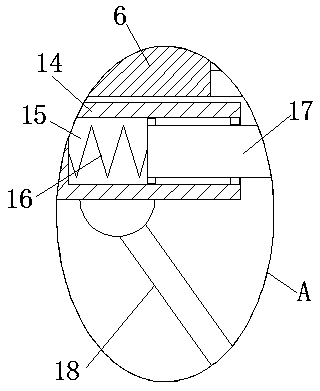

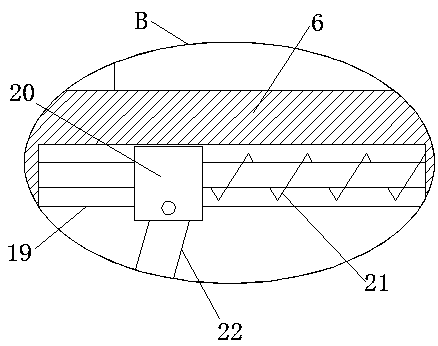

[0026] refer to Figure 1-6 , a parallel groove clamp, including a fixed seat 1, the top of the fixed seat 1 is provided with a connecting groove 2, the bottom inner wall of the connecting groove 2 is provided with two lower clip bodies 3, and the top of the fixed seat 1 is provided with two sockets Slot 4, two insertion rods 5 are movably installed in the two slots 4, and the tops of the two insertion rods 5 are slidingly connected with the same pressure plate 6, and the top of the pressure plate 6 is fixedly installed with two bearing seats 7, two bearings The same threaded rod 9 is rotatably installed on the seat 7, and a rotating block 8 is installed on the side of one bearing seat 7 of the two bearing seats 7 away from the other bearing seat 7, and one end of the threaded rod 9 is fixedly installed on the rotating block 8 On, two transmission shafts 10 are threadedly connected on the threaded rod 9, and two transmission shafts 10 are provided with threaded holes, and the ...

Embodiment 2

[0035] refer to Figure 1-6 , a parallel groove clamp, including a fixed seat 1, the top of the fixed seat 1 is provided with a connecting groove 2, the bottom inner wall of the connecting groove 2 is provided with two lower clip bodies 3, and the top of the fixed seat 1 is provided with two sockets Slot 4, two insertion rods 5 are movably installed in the two slots 4, and the tops of the two insertion rods 5 are all slidably connected with the same pressure plate 6, and the top of the pressure plate 6 is fixedly installed with two bearing seats 7 by welding. The same threaded rod 9 is rotatably installed on the two bearing seats 7, and a rotating block 8 is installed on the side of one bearing seat 7 away from the other bearing seat 7 in the two bearing seats 7, and one end of the threaded rod 9 is fixedly installed by welding. On the rotating block 8, two transmission shafts 10 are threadedly connected on the threaded rod 9, and threaded holes are provided on the two transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com