A kind of color adjustment device and color adjustment method thereof

The technology of a coloring device and a coloring tank, which is applied in the field of painting or dyeing, can solve the problems of uneven mixing, time-consuming and laborious manual color matching, etc., and achieve the effects of improving the batching efficiency, reducing the workload of personnel, and increasing the promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

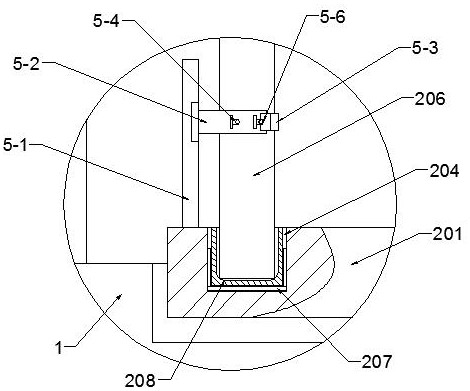

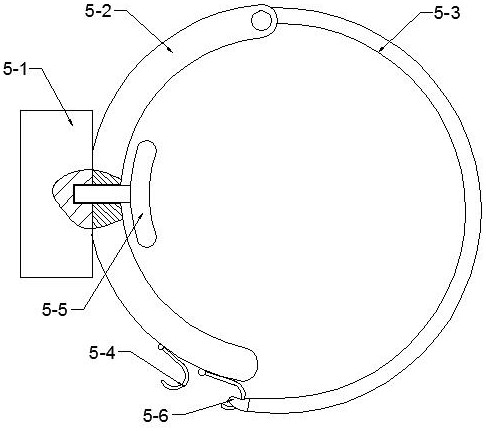

[0032] Example 1, such as figure 1 As shown, a toning device includes an operating platform 1, and the operating platform can be a height-adjustable platform. The operating platform 1 is provided with a rotary storage tank mechanism 2, a feeding mechanism 3 and a stirring mechanism 4, and the rotary storage tank mechanism 2 can be used to store a color mixing tank. The feeding mechanism 3 is used for injecting the coloring material into the coloring tank placed on the rotating storage tank mechanism. Stirring mechanism 4 is used for stirring the color material in the tinting tank. The feeding mechanism 3 and the stirring mechanism 4 are respectively located on both sides of the rotary storage tank mechanism 2 and correspond to the rotary storage tank mechanism 2. The feeding mechanism 3 and the stirring mechanism 4 perform feeding and stirring in an orderly manner without interference. The feeding mechanism 3 and the stirring mechanism 4 are respectively connected with the c...

Embodiment 2

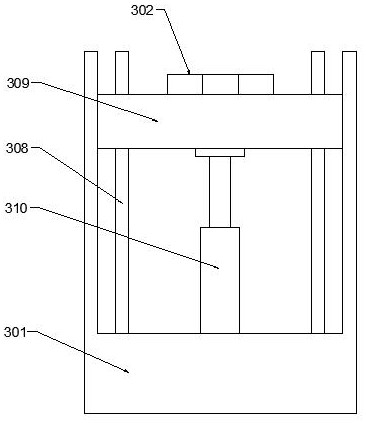

[0035] Example 2, such as Figure 4As shown, a toning device, the feeding mechanism 3 includes a left support base 301, the left support base 301 is fixedly connected to the operating platform, and a swing arm 302 is arranged on the left support base 301, that is, the swing arm can be rotated around the connection point turn. The swing arm 302 is provided with a vertical shaft 303, the vertical shaft 303 is rotationally connected with the swing arm 302 through the second bearing 304, the upper end of the vertical shaft 303 is connected with the first motor 305 arranged on the swing arm through a gear pair, The first motor 305 is connected with the controller, and the bottom of the vertical shaft 303 is fixedly provided with a disk seat 306, that is, the center of the vertical shaft coincides with the center of the disk seat and the two are fixedly connected. The shaft drives the disc seat to rotate. The plate base 306 is provided with at least two injection guns 307, and the...

Embodiment 3

[0040] Embodiment 3, a toning method of a toning device, comprising the following steps:

[0041] S1: According to the number of types of toning, select the corresponding number of toning tanks to achieve the simultaneous deployment of multiple coloring materials;

[0042] S2: Place the toning cans one by one in the corresponding positioning groove of the tray, and clamp and fix the toning cans through the clamping mechanism; ensure the stability of the toning cans during the stirring process;

[0043] S3: start the second motor, the second motor drives the swing arm to rotate, and drives the injection gun to rotate to the top of the color tank; then start the first motor, the first motor drives the plate base to rotate through the vertical shaft, and the different The injection gun of the color material injects the color material into the corresponding toning tank; different injection guns correspond to the same toning tank to realize the injection of multiple color materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com