Execution assembly of electronic expansion valve

An electronic expansion valve and actuator technology, which is applied to valve operation/release devices, lift valves, valve details, etc., can solve problems such as increased processing costs, increased friction of threaded screws, and up and down jumping of actuator components, reducing Cost and frictional resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further specifically described below through examples.

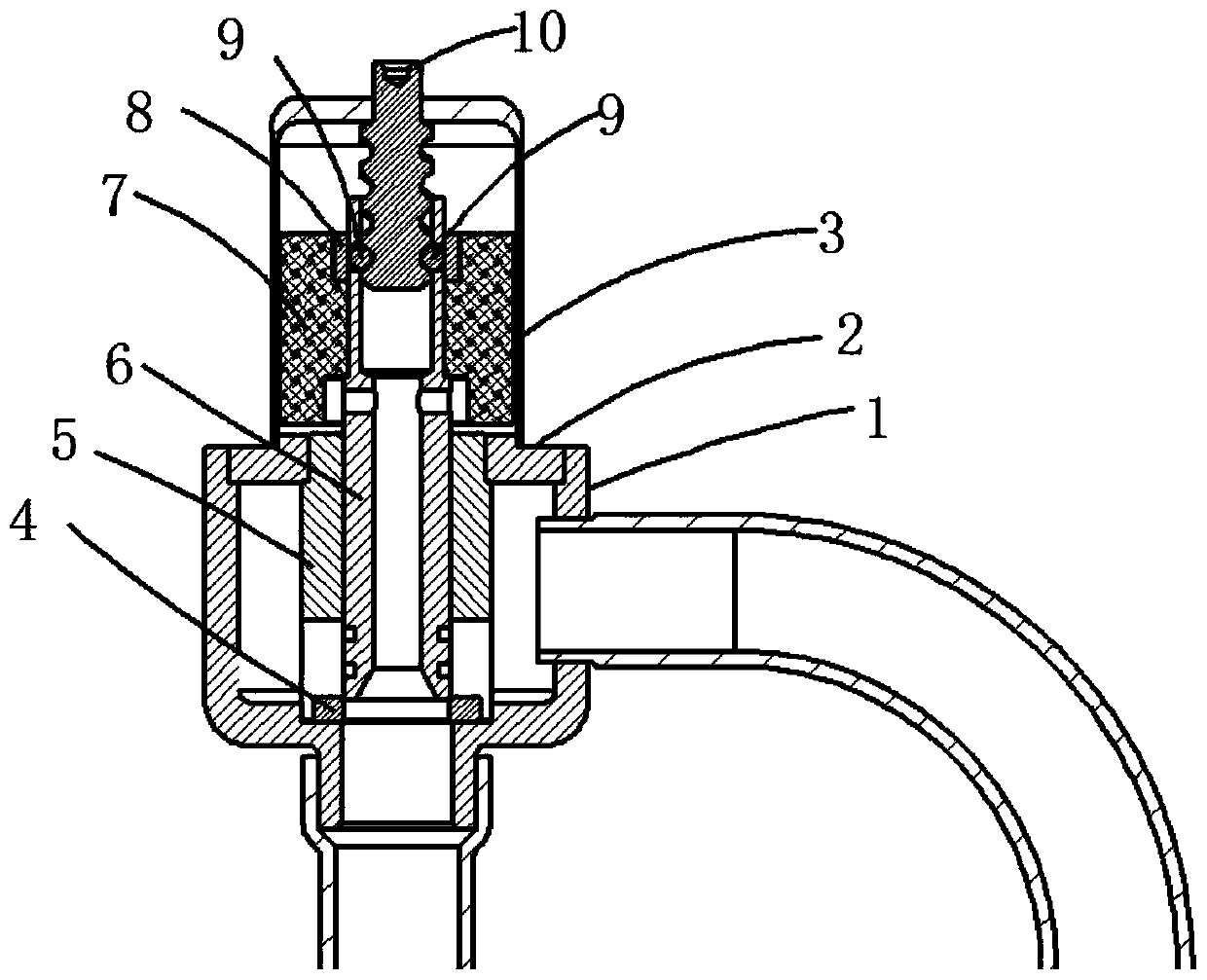

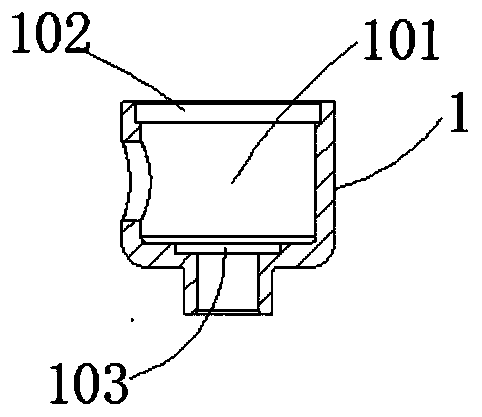

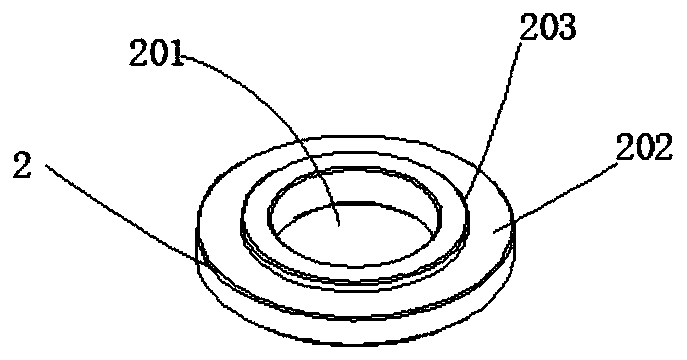

[0033] like figure 1 As shown, an executive assembly of an electronic expansion valve includes a valve seat 1, a flange 2, an isolation sleeve 3, a valve ring 4, a guide sleeve 5, a valve column 6, an inner magnetic ring 7, a screw sleeve 8, and a small steel ball 9. Rolling screw 10.

[0034] In the present invention, a flange 2 is provided above the valve seat 1, and the flange 2 and the valve seat 1 are connected together by welding; the valve column 6 is installed on the The guide sleeve 5 on the valve seat 1, the guide sleeve 5 is embedded in the valve seat 1 through the middle hole 201 of the flange 2; the inner magnetic ring 7 passes through the middle hole on the inner magnetic ring 7 702 is inserted into the valve column 6; the flange 2 is connected with the spacer sleeve 3 by welding; the rolling screw 10 is inserted into the first column hole 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com