Discharge adjusting device of tobacco primary processing and mixing cabinet and discharging device

A technology of adjusting device and blending silk, which is applied to conveyor control device, tobacco, measuring device, etc., can solve the problems of uniform flavoring effect of shredded tobacco, insufficient material supply, damage to mechanical parts and electrical parts, etc., and achieve the process of flavoring control. Stable and reliable, uniform and stable discharge flow, controllable and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

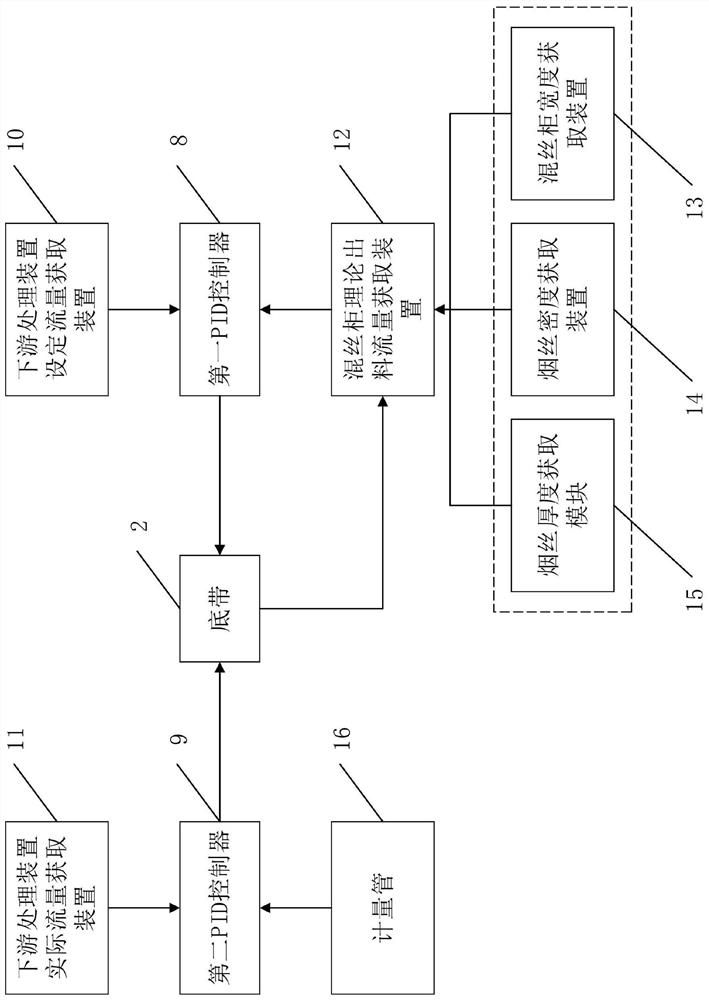

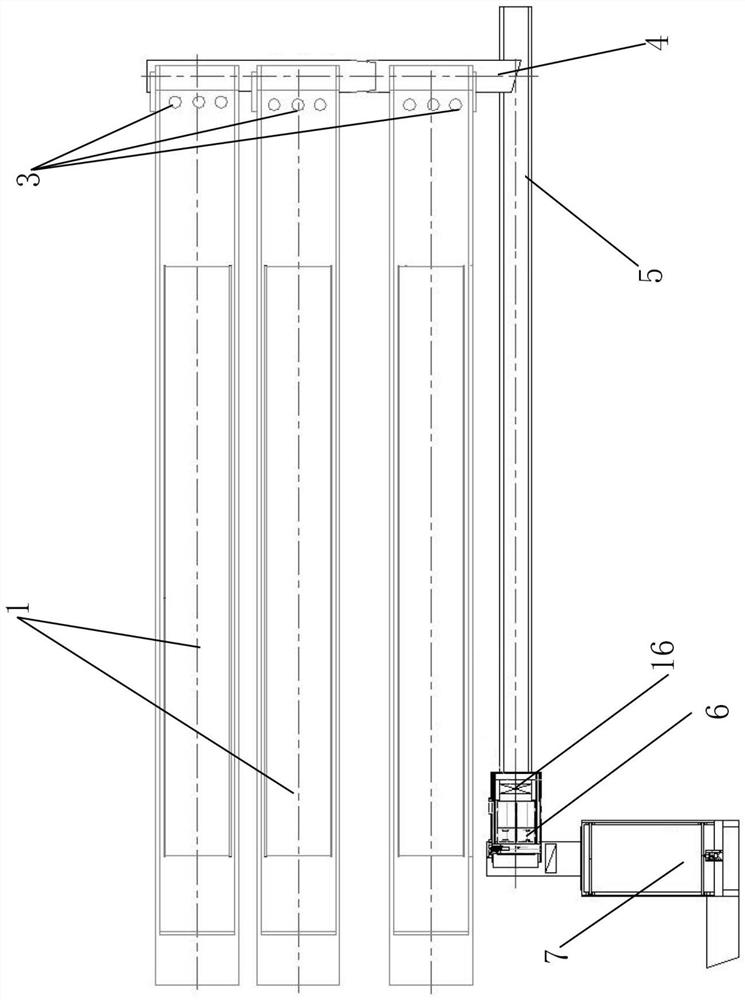

[0044] figure 1 It is a structural schematic diagram of the output regulating device of the tobacco shred mixing cabinet in this embodiment. Such as figure 1 As shown, Embodiment 1 of the present invention provides a discharge adjustment device for tobacco silk mixing cabinet, which includes several thickness gauges 3, and several thickness gauges 3 are arranged above the bottom belt 2 of the silk mixing cabinet 1 for collecting The thickness of the shredded tobacco in the blending cabinet.

[0045] The output regulating device of the silk mixing cabinet also includes a metering tube 16 , and the metering tube 16 is arranged between the downstream processing device and the silk mixing cabinet 1 . The downstream processing device is arranged downstream of the silk mixing cabinet 1 .

[0046] The downstream processing device is preferably an electronic belt scale 6, the metering tube 16 is arranged at the entrance of the electronic belt scale 6, and the downstream of the electr...

Embodiment 2

[0069] This embodiment differs from Embodiment 1 in that:

[0070] Preferably, the thickness gauge 3 is an ultrasonic sensor. Further, several thickness gauges 3 are evenly distributed at the discharge end of the silk mixing cabinet.

[0071] In this embodiment, preferably, the number of the silk mixing cabinets 1 is three, and the three silk mixing cabinets 1 are arranged side by side. In addition, the number of thickness gauges 3 corresponding to each silk mixing cabinet 1 is three. Middle and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com