Ventilation tail end silencer

A technology for mufflers and ventilation equipment, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problems of uneven airflow and turbulence at the air inlet, and achieve the effect of reducing the impact and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

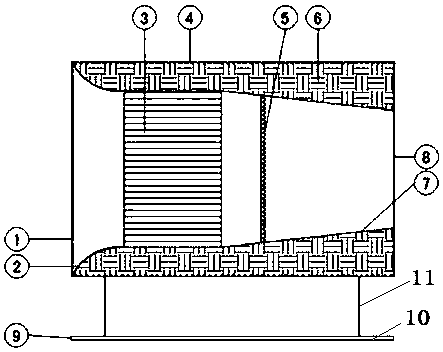

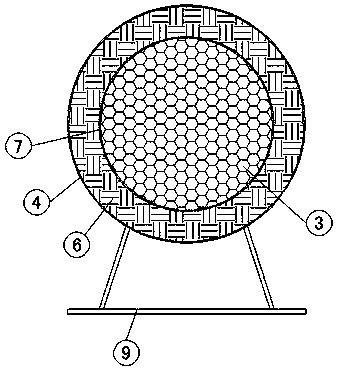

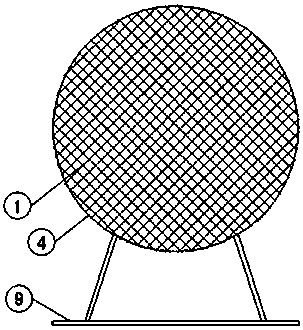

[0019] figure 1 , figure 2 , image 3 , Figure 4 As shown, a ventilation terminal muffler is used as the air inlet and outlet of the ventilation equipment, and consists of a wire mesh 1, a flared end 2, a muffler section 3, a support cylinder 4, a rectifying net 5, sound-absorbing cotton 6, and a transition Section 7, connecting flange 8, and base 9 are formed.

[0020] The casing bolts of the base are fixed on the concrete prefabricated platform, and the support tube is welded on the base; the wire mesh is installed outside the tuyere end of the support tube; Among them, one side is connected to the flaring end, and the other side is connected to the transition section to form the main ventilation channel of the equipment; the sound-absorbing cotton is filled between the channel formed by the muffler section, the flaring end, and the transition section and the support cylinder; the rectification net is installed in the transition section.

[0021] The base 9 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com