Rolling bearing residual life prediction method

A rolling bearing and life prediction technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low training efficiency, variable load conditions, low prediction accuracy of rolling bearing remaining life, etc., to improve prediction accuracy, The effect of improving training efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

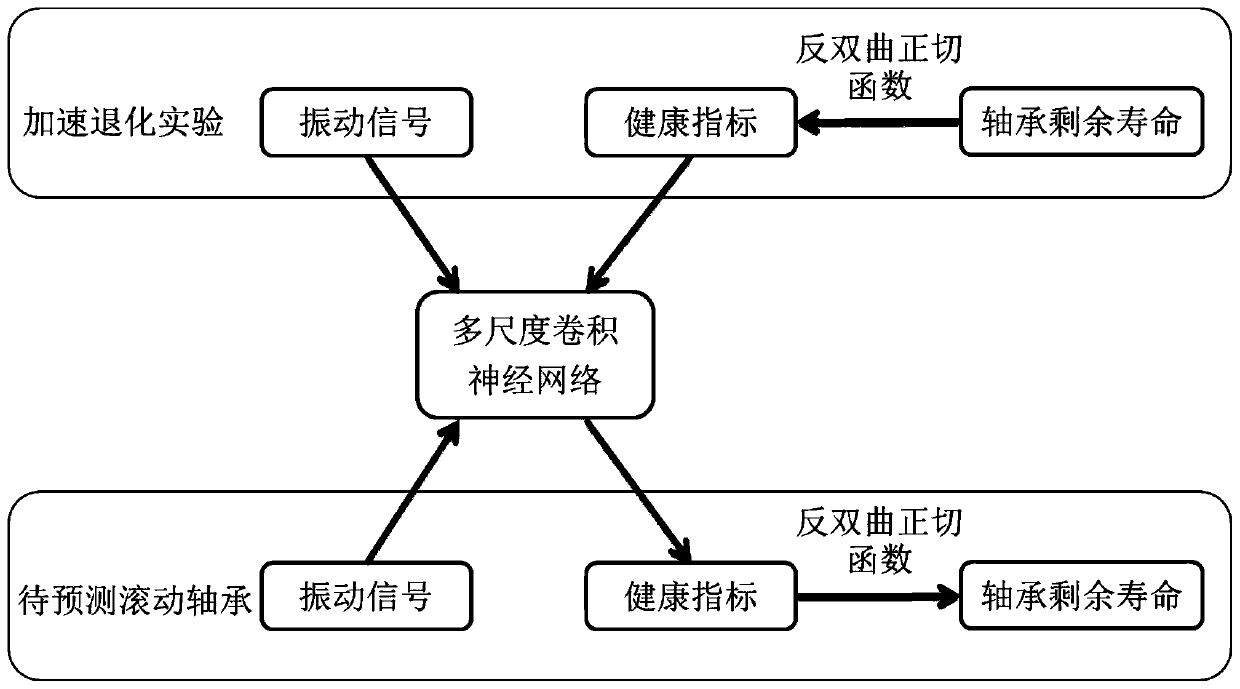

[0017] see figure 1 , the method for predicting the remaining life of a rolling bearing according to the present invention comprises steps:

[0018] S1. Use a number of unused bearings of the same type as the bearing whose life is to be predicted to conduct accelerated degradation experiments respectively. In the experiment, the vibration signal of the bearing is collected every 10 seconds or 20 seconds until the bearing fails completely, and multiple The whole life vibration signal of the bearing;

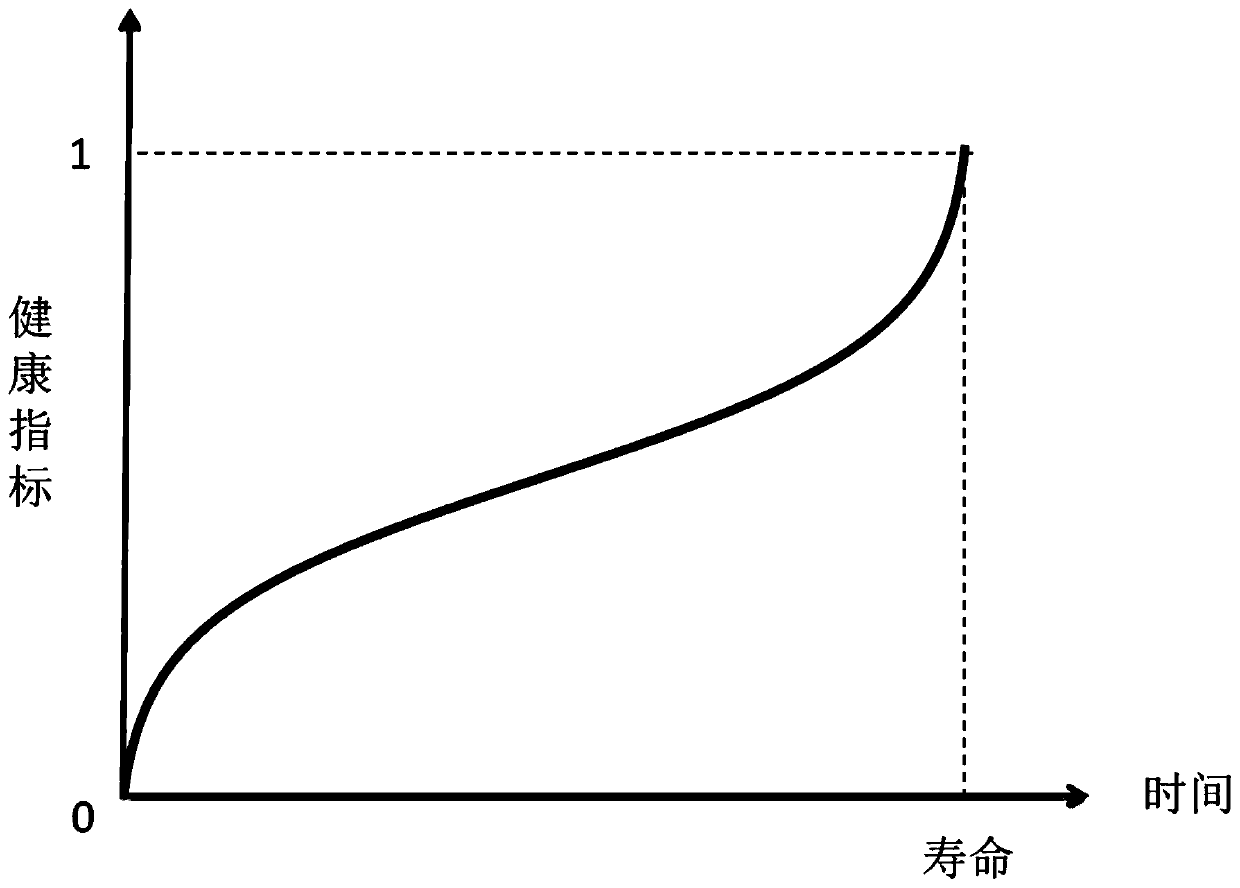

[0019] S2. Using the inverse hyperbolic tangent function to convert the remaining life of the bearing into its health index HI;

[0020] S3. Establish a multi-scale convolutional neural network model, the input of which is the vibration signal of the bearing, and the output is the health index of the bearing, and the multi-scale convolutional neural network is trained with the data of a plurality of bearings obtained in step S1;

[0021] S4. Utilize the acceleration sensor to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com