3D printing hierarchical control algorithm

A 3D printing and layered control technology, applied in the field of 3D printing, can solve the problems of time-consuming establishment of topology data, difficulty in completely eliminating invalid judgment of positional relationship, large memory usage, etc. Short, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

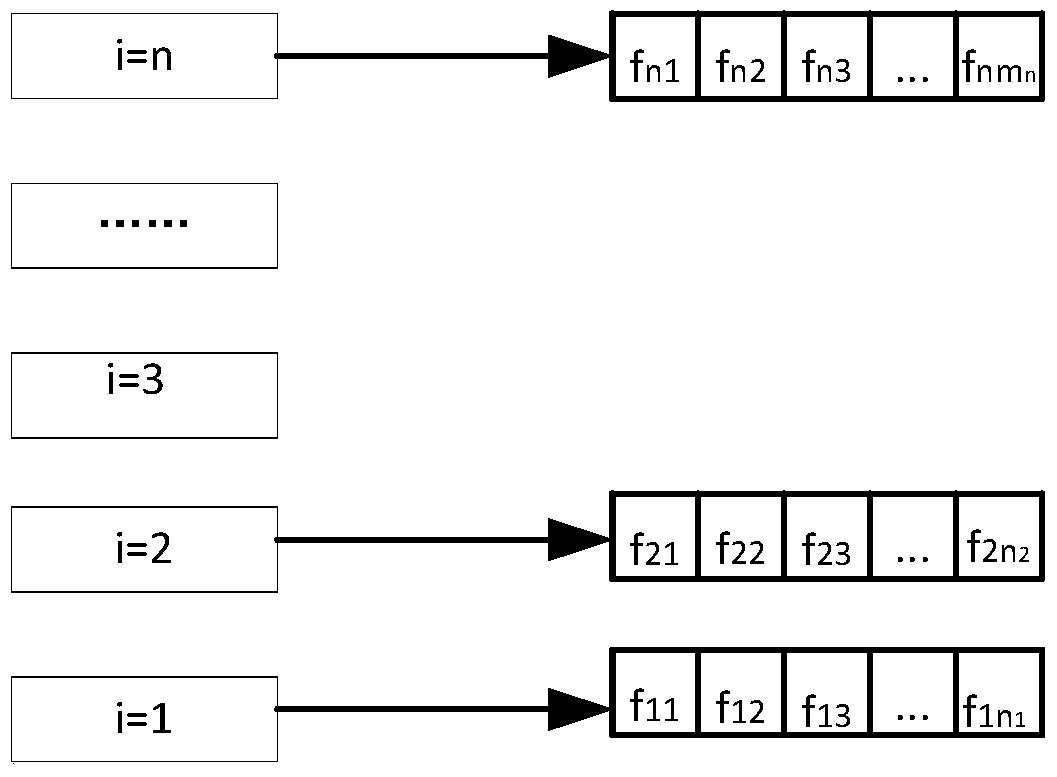

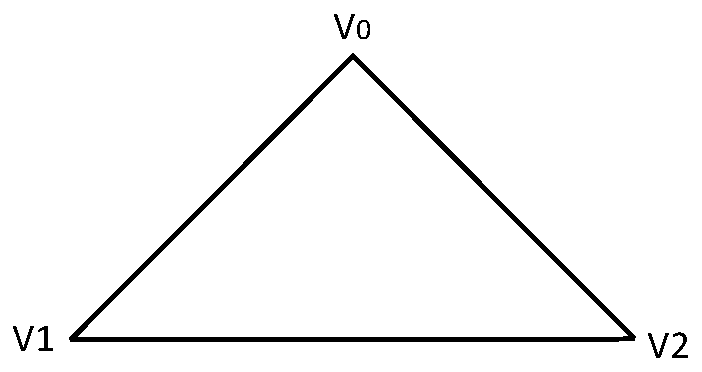

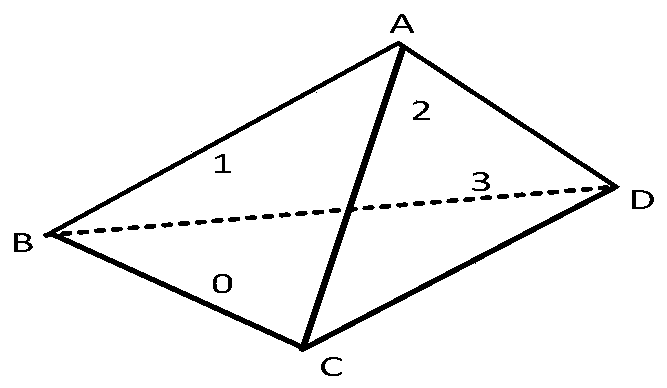

[0055] The invention relates to a layered control algorithm for 3D printing, which is a recursive layered algorithm based on grouping and sorting directed weighted graphs. The algorithm first analyzes the STL model files in 3D printing, and sorts all the triangular patches in groups; then establishes a hierarchical relationship matrix for the triangular patches after grouping and sorting (that is, establishes a directed weighted graph data structure); Afterwards, recursively search the directed weighted graph for the active triangles (recursively search the active triangles in the data structure of the directed weighted graph, that is, the topology), find the adjacent triangles, record their weight data information, and pass the weight The value data information directly finds the edge, and then obtains the intersection point of the edge and the section, and finally generates the profile data of the section.

[0056] A 3D printing layered control algorithm of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com