Degradable inward-turning annular pressure type biological tube anastomat

A stapler and biological technology, applied in the field of medical devices, can solve the problems of uneven healing time and decreased healing effect, and achieve the effect of reducing complications and increasing the quality of healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

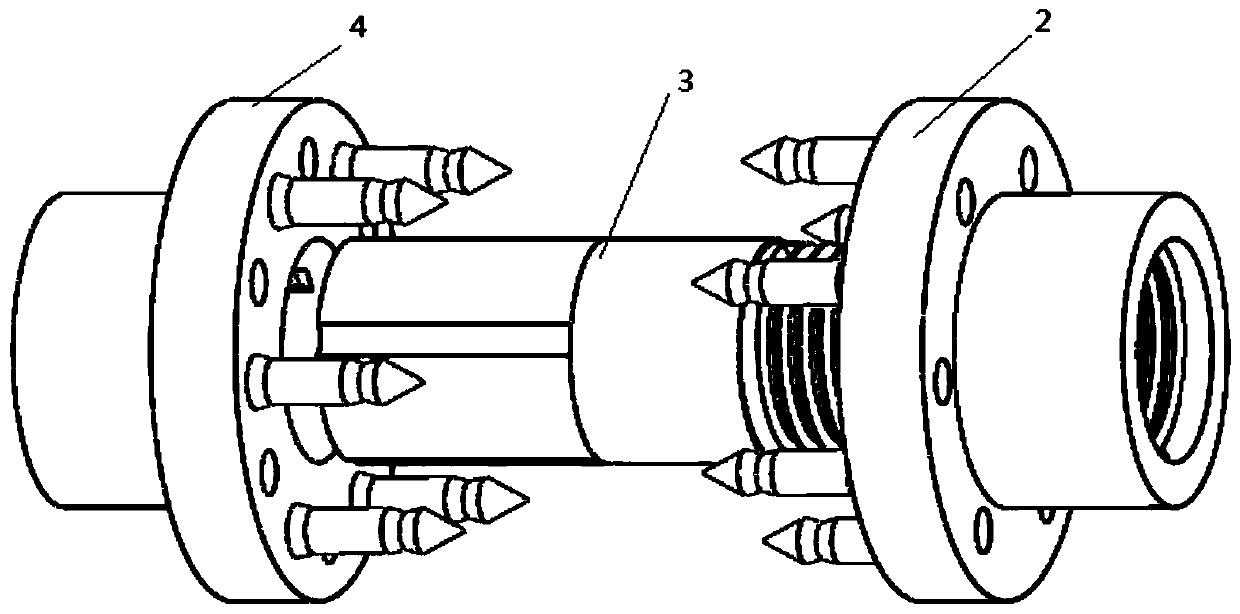

[0026] Such as figure 1 As shown, a degradable inversion ring pressure biological tube stapler, including the bottom 2 of the stapler, one end of the bottom 2 of the stapler and the guide rail 3 of the stapler are threaded, and the other end of the guide rail 3 of the stapler is connected with 4 holes on the top of the stapler The shafts are mated and connected, and the guide rail 3 of the stapler is used for angular alignment.

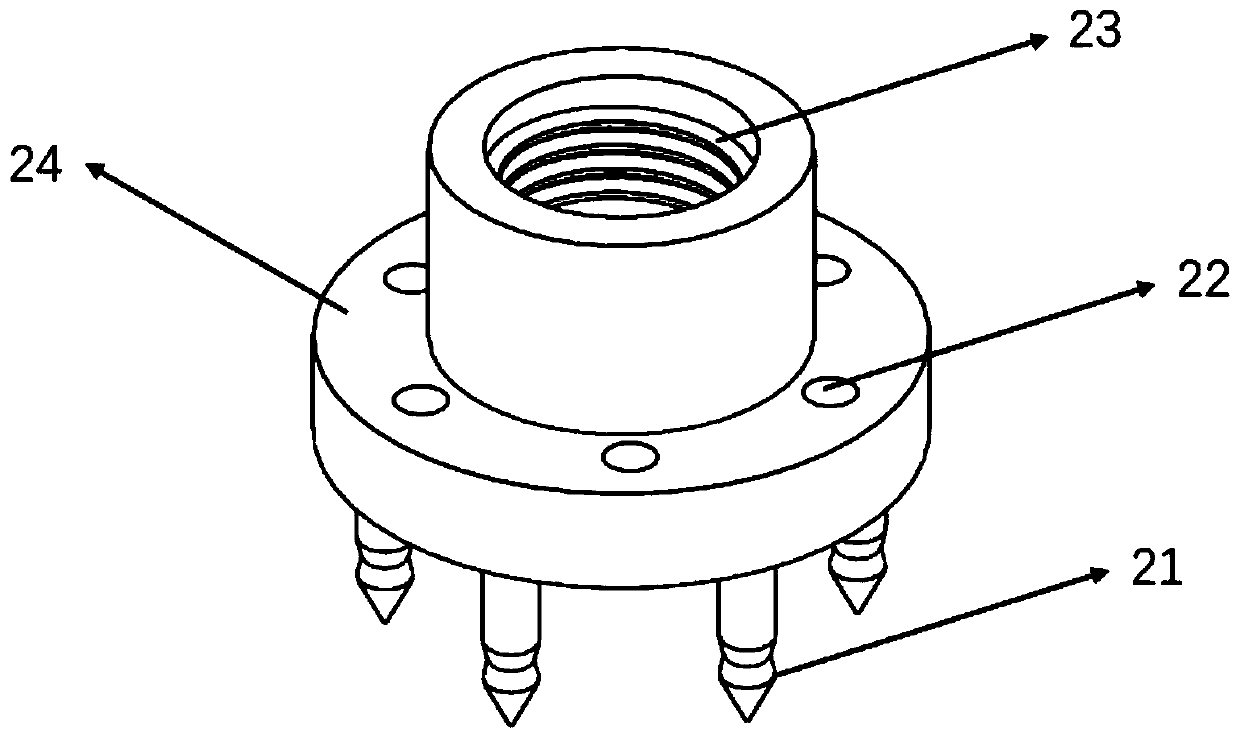

[0027] Such as figure 2 As shown, the bottom 2 of the stapler includes a first ring 24, one side of the first ring 24 is connected with a first cylinder 23 with an internal thread, and the other side of the first ring 24 is provided with uniformly distributed The first metal nails 21 and the first anastomotic holes 22 are arranged alternately;

[0028] In this embodiment, the first ring 24 is provided with 6 first metal n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com