Packaging printing sheet locating method

A positioning method and technology for packaging sheets, which are applied in the directions of packaging material feeding devices, packaging, transportation packaging, etc., can solve the problems of misalignment between the packaging shape and the pattern of the plastic sheet, and the cumulative error between the pattern of the plastic sheet and the packaging shape is large. , to improve the appearance quality and ensure the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

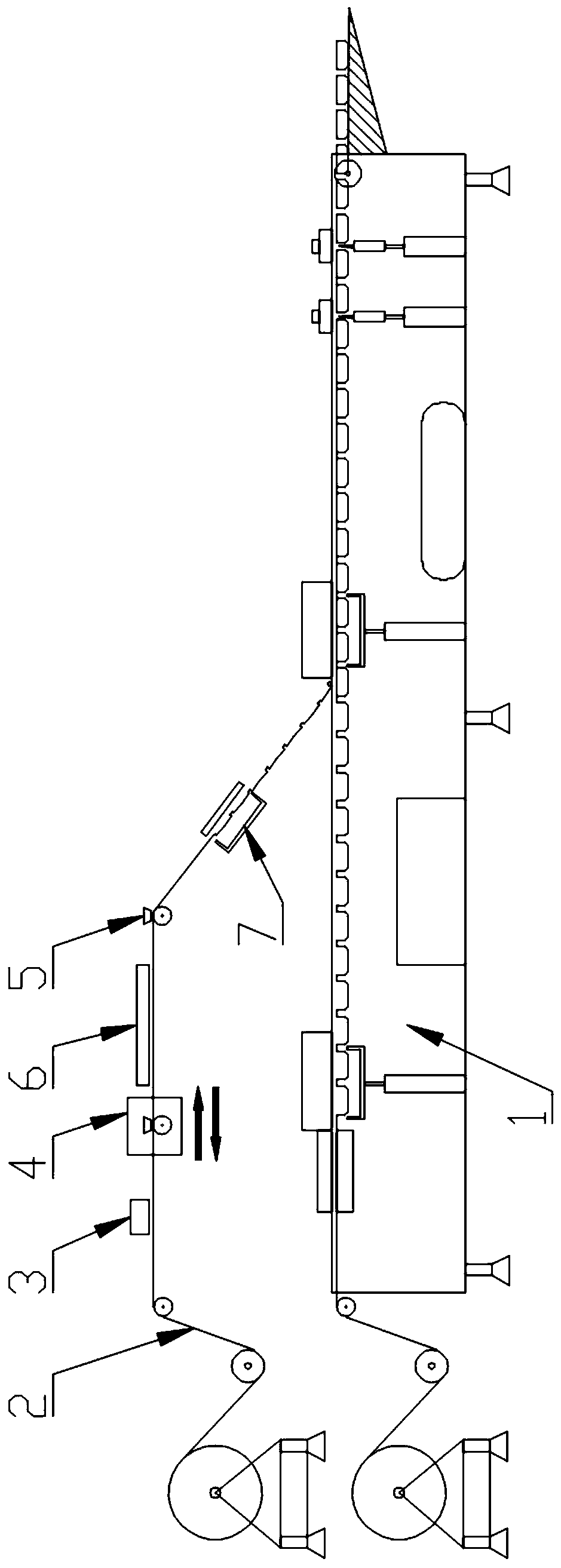

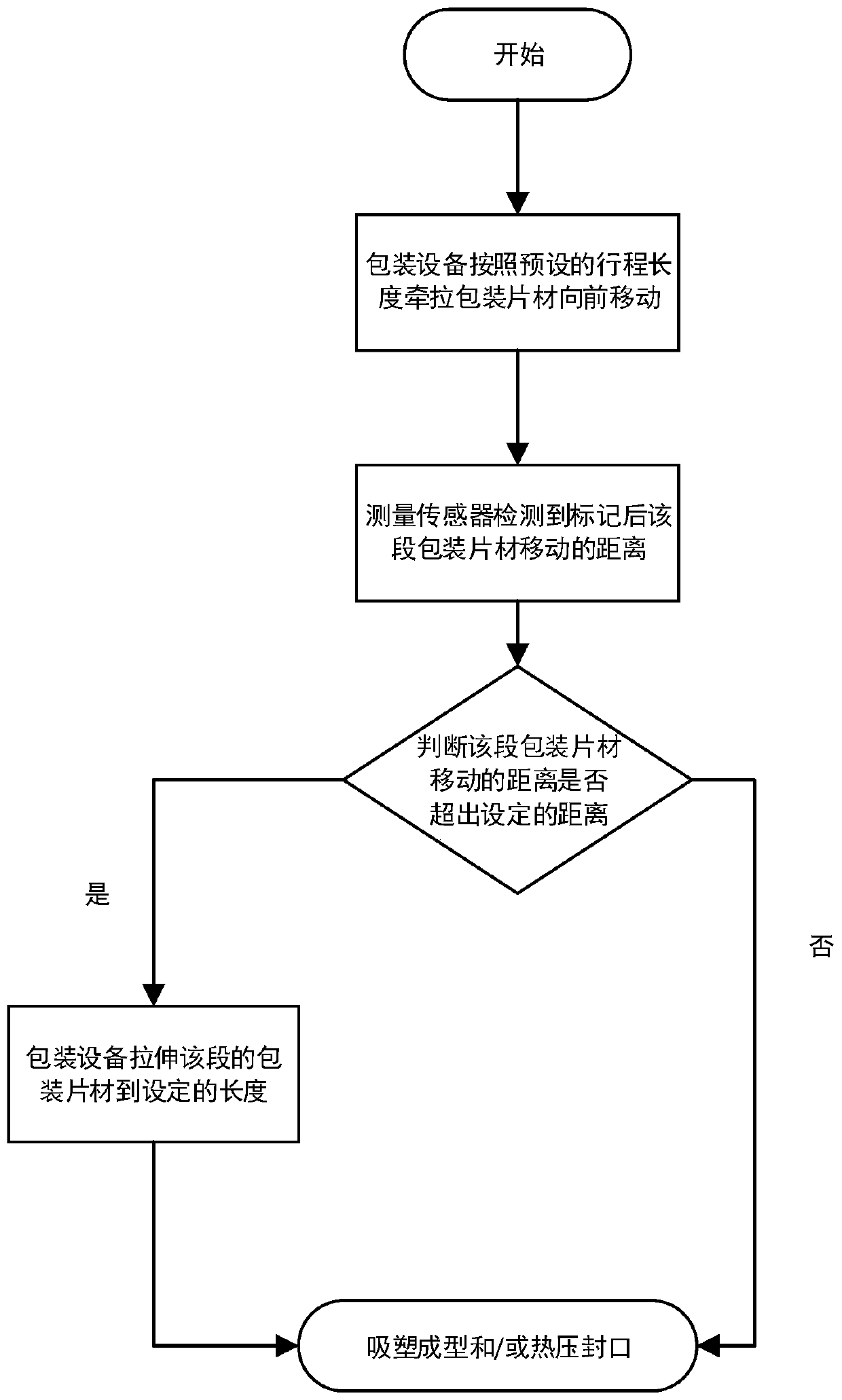

[0030] see figure 1 , figure 2 and Figure 4 As shown, the embodiment of the present invention provides a printing sheet positioning method for packaging, including the following steps:

[0031] Step 1. Cooperate the packaging sheet 2 with the printed pattern with the packaging equipment 1, and the packaging equipment 1 pulls the packaging sheet 2 to move in the direction A according to the preset stroke length; the preset stroke length is set according to the specific packaging product, The length is a fixed value.

[0032] Step 2. During the movement of the packaging sheet 2 to the direction A, the sensor 3 detects the mark 21 on the packaging sheet 2 and then performs displacement measurement; the sensor 3 detects the marking 21 on the packaging sheet 2 and starts timing After the packaging sheet 2 stops moving to the A direction, stop timing, and calculate the distance that the packaging sheet 2 moves after the sensor 3 detects the mark 21 by the time period of timing ...

Embodiment 2

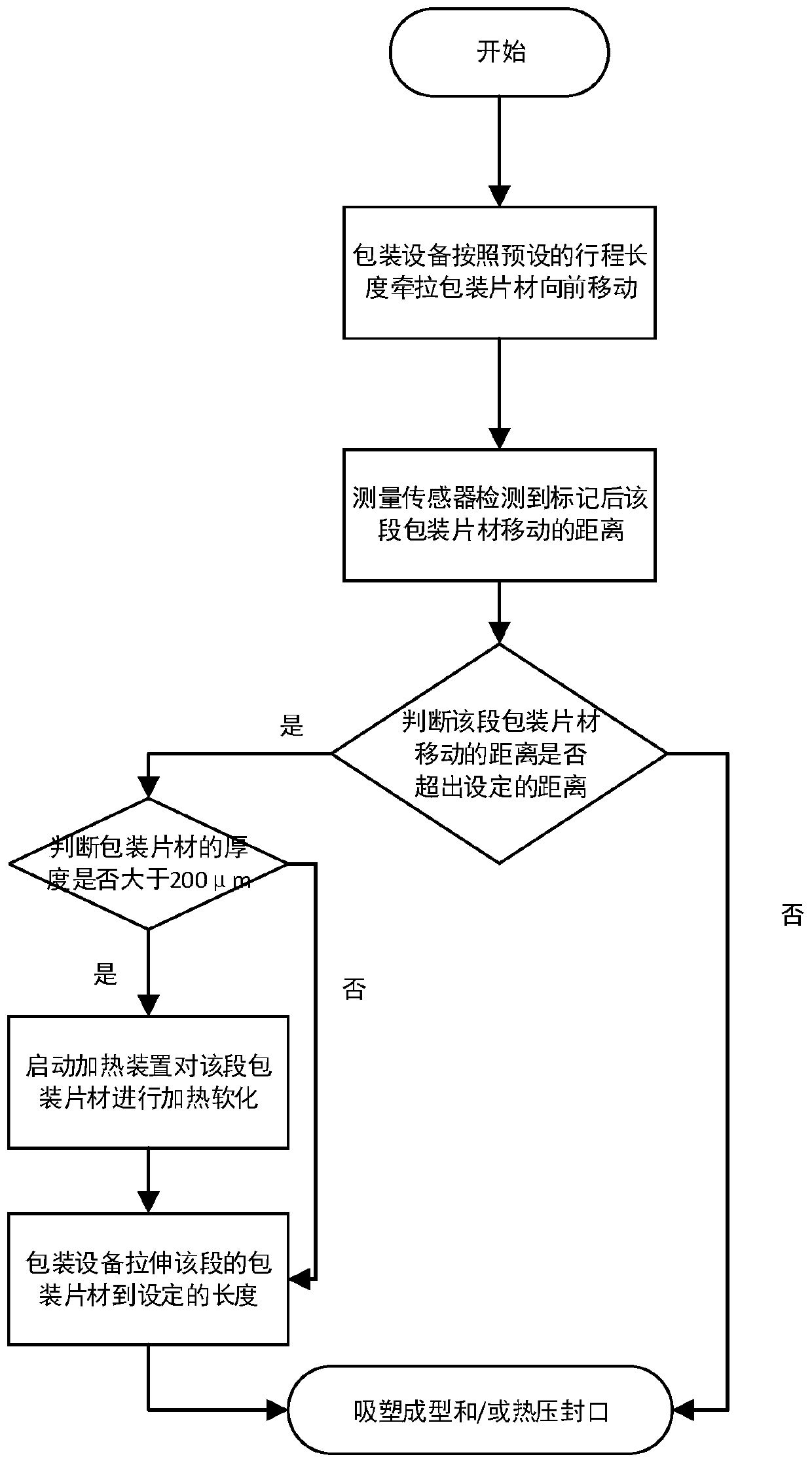

[0041] see figure 1 , image 3 and Figure 4 As shown, the embodiment of the present invention provides a printing sheet positioning method for packaging, including the following steps:

[0042] Step 1. Cooperate the packaging sheet 2 with the printed pattern with the packaging equipment 1, and the packaging equipment 1 pulls the packaging sheet 2 to move in the direction A according to the preset stroke length; the preset stroke length is set according to the specific packaging product, The length is a fixed value.

[0043] Step 2. During the movement of the packaging sheet 2 to the direction A, the sensor 3 detects the mark 21 on the packaging sheet 2 and then performs displacement measurement; the sensor 3 detects the marking 21 on the packaging sheet 2 and starts timing After the packaging sheet 2 stops moving to the A direction, stop timing, and calculate the distance that the packaging sheet 2 moves after the sensor 3 detects the mark 21 by the time period of timing and...

Embodiment 3

[0050] see Figure 4 Shown, the difference between this embodiment and embodiment 1, embodiment 2 is:

[0051] The sensor 3 is a color mark sensor, and the mark 21 is set at the boundary position between two adjacent printing patterns in the longitudinal direction of the packaging sheet 2. When the color mark sensor detects the mark 21 of this segment of the packaging sheet 2, the color mark sensor The timing starts after receiving the reflected signal of the marker 21 . If there are N marks 21 on this section of packaging sheet 2, N is a positive integer greater than 1, N marks 21 are arranged evenly along the longitudinal direction of the packaging sheet 2, and there is a printed pattern between two adjacent marks 21 When the color mark sensor detects the Nth mark 21 of the section of packaging sheet 2, the color mark sensor starts timing after receiving the reflection signal of the Nth mark 21.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com