Washing machine

A technology for washing machines and washing tubs, applied in the field of washing, which can solve the problems of raising the overall center of gravity of the washing tub and the outer tub, destroying the washing tub, and increasing the weight of the upper part of the washing tub, so as to reduce washing water consumption, save washing water consumption, and improve The effect of drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

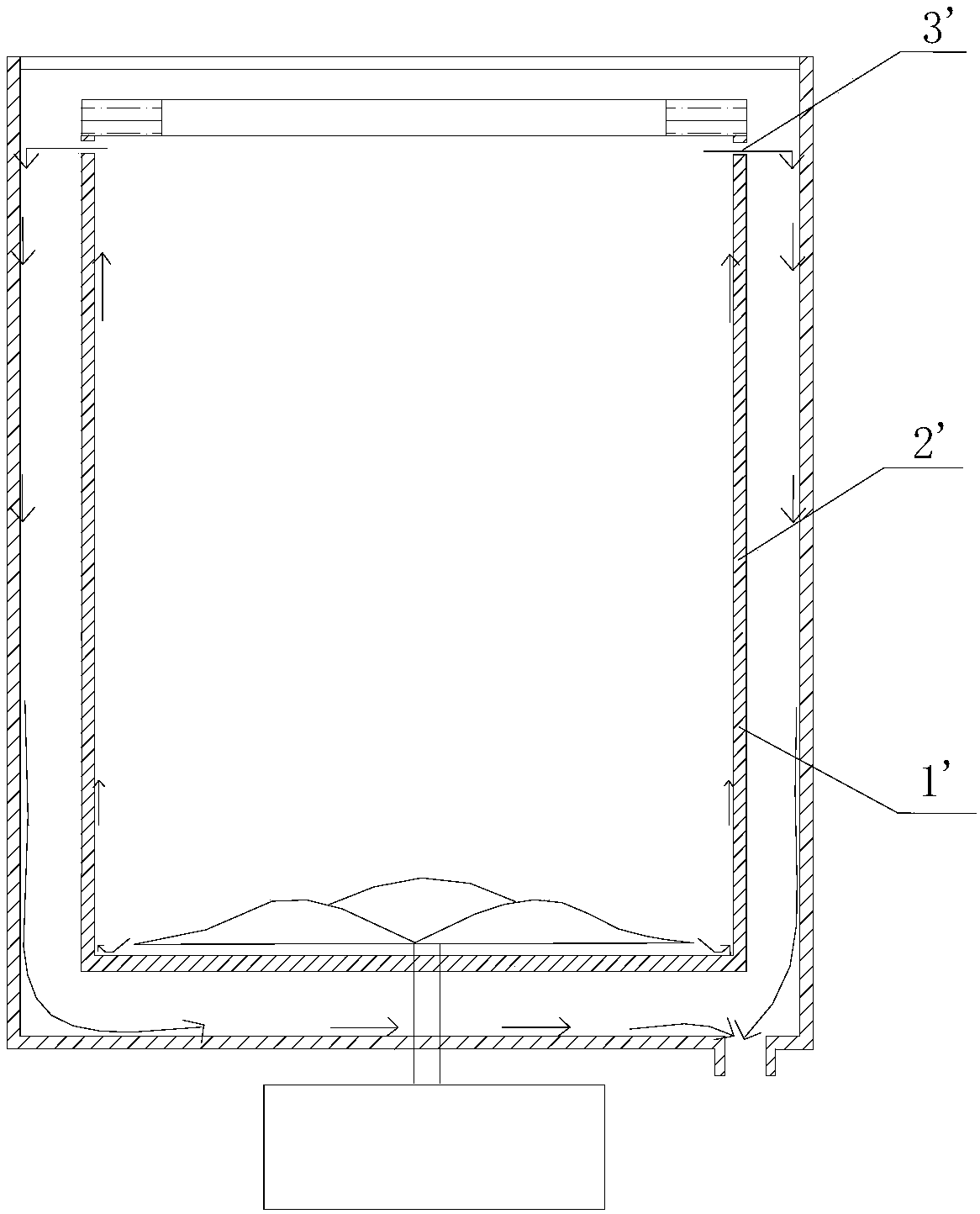

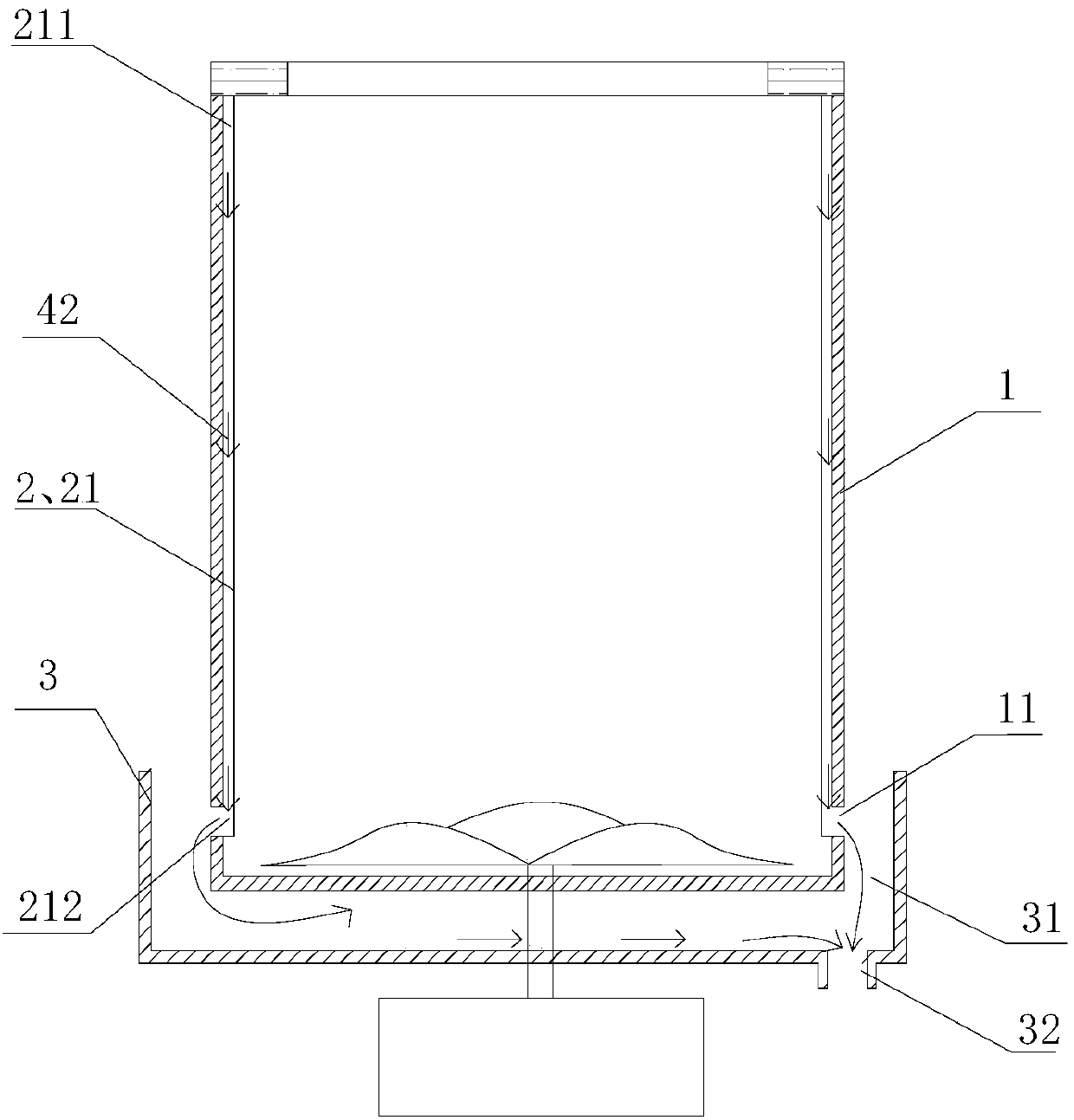

[0062] Such as figure 2 As shown, the drainage assembly 2 described in this embodiment includes a first drainage channel 21 that is located inside the circumferential area where the peripheral wall of the washing tub 1 is located and conducts water from top to bottom. It enters into the first drainage channel 21 along the circumference of the washing tub, and the lower part is a water outlet 212 for draining water to the outside of the washing tub.

Embodiment 2

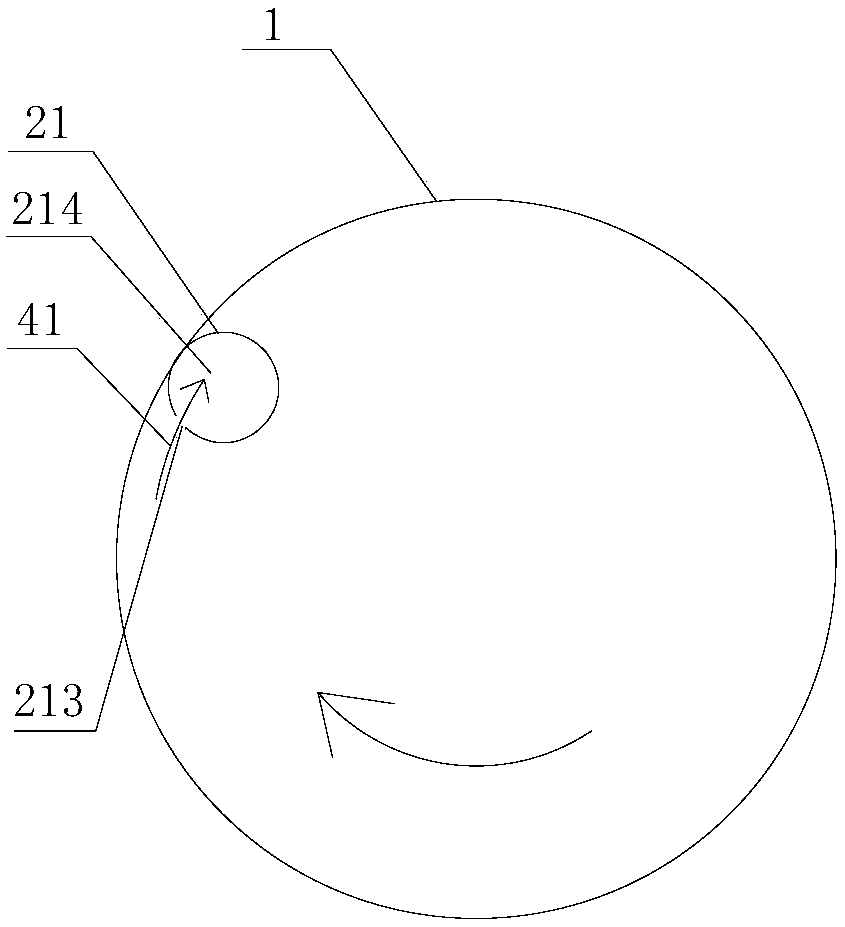

[0064] Such as figure 2 As shown, on the basis of Embodiment 1, the drainage assembly 2 of this embodiment also includes a first water outlet 11 arranged on the peripheral wall of the washing tub 1, or the first water outlet is arranged on the bottom wall, such as image 3 with Figure 4 As shown, the first drainage channel 21 is installed on the inner peripheral wall of the washing tub 1, the first drainage channel 21 is covered with the first drainage port 11 at the lower part, and the water inlet 213 is provided at the upper part and is defined from the water inlet 213 down to the The second path 42 of the first water outlet 11 .

[0065] Further, such as image 3 As shown, the first drainage channel 21 is an independent structure, the upper part has a water inlet 213 corresponding to the radial side wall, the interior has a water guiding chamber 214 forming a second path, and the lower part has a outlet, or, if Figure 4 As shown, the first drainage channel 21 is a co...

Embodiment 3

[0069] Such as Figure 5 As shown, on the basis of Embodiment 1, the surrounding wall of the washing tub 1 in this embodiment is provided with at least one groove 12 with an opening along the up and down direction, and the groove bottom of the groove 12 protrudes inwardly from the inside of the washing tub 1. The peripheral wall, the opening of the groove 12 is covered with a cover plate 13, which constitutes the first drainage channel 21, and the groove 12 has a second path 42 for leading water from top to bottom (see figure 2 ).

[0070] Preferably, the upper side wall of the groove 12 has a water inlet 213 , and the lower part of the cover plate 13 has a water outlet.

[0071] Also preferably, the water inlet 213 is arranged on the radial side wall of the groove 12 that is consistent with the dehydration rotation direction of the washing tub, and the opening direction of the water inlet 213 is consistent with the dehydration rotation direction of the washing tub 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com