A kind of semiconductor wafer flattening equipment

A planarization and semiconductor technology, applied in the field of semiconductor wafer planarization equipment, can solve the problems of wafer waste and small semiconductor wafers, and achieve the effect of flattening transportation and avoiding mutual stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

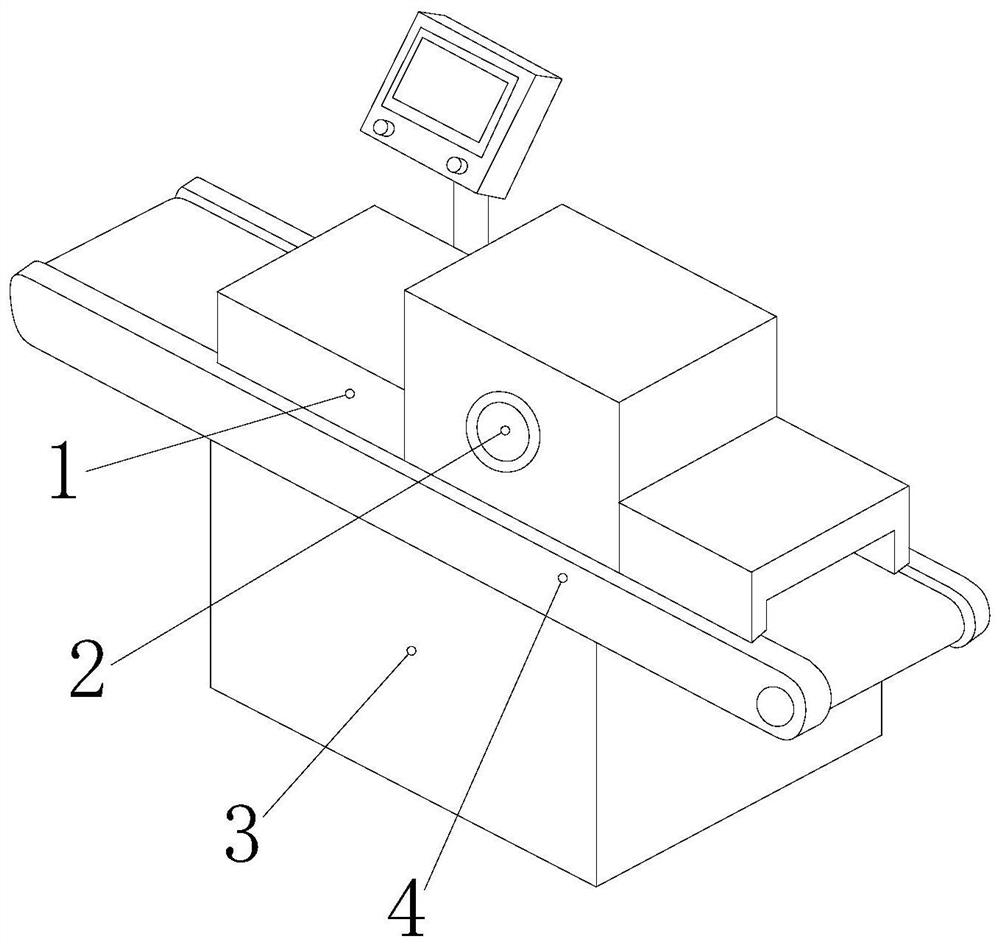

[0024] see Figure 1-Figure 6 , the present invention provides a kind of semiconductor wafer flattening equipment, its structure comprises outer cover 1, flat device 2, base 3, processing table 4, described outer cover 1 is installed on the processing table 4, described processing table 4 and outer cover 1 mechanical Welding, the outer cover 1 is set up in a U-shaped structure, the flat device 2 is installed in the outer cover 1, and the processing table 4 is fixedly connected to the base 3;

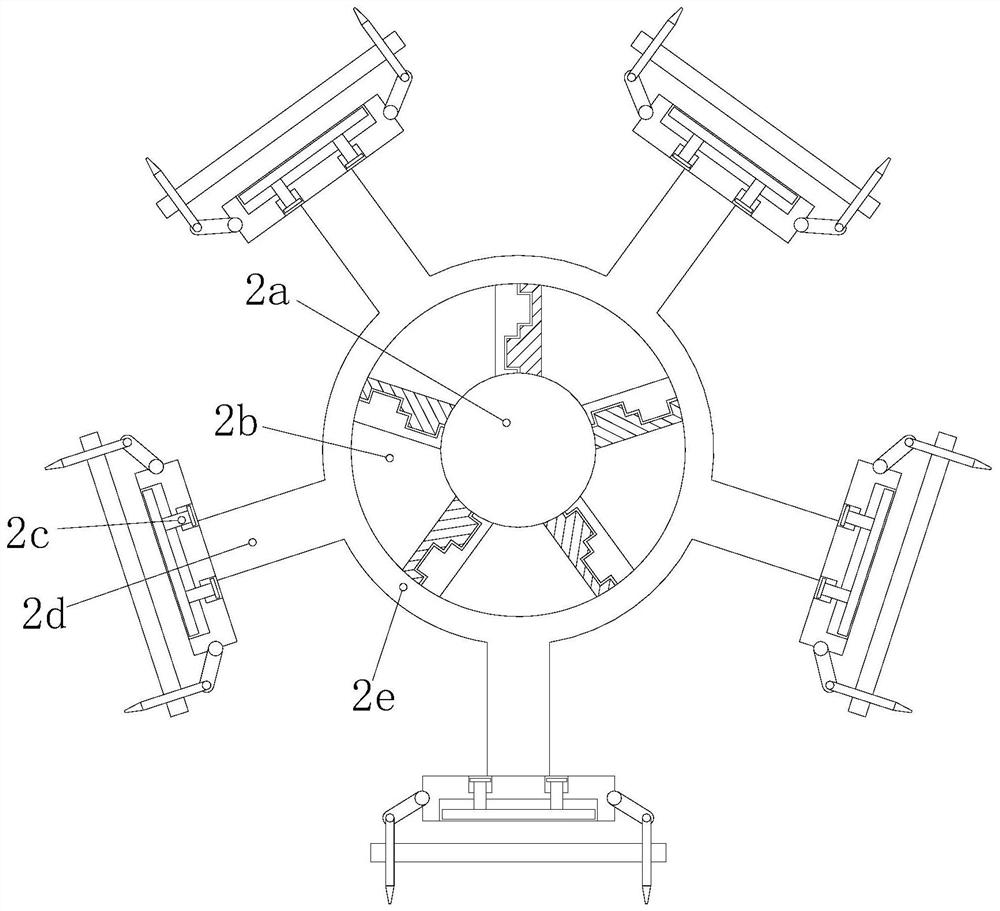

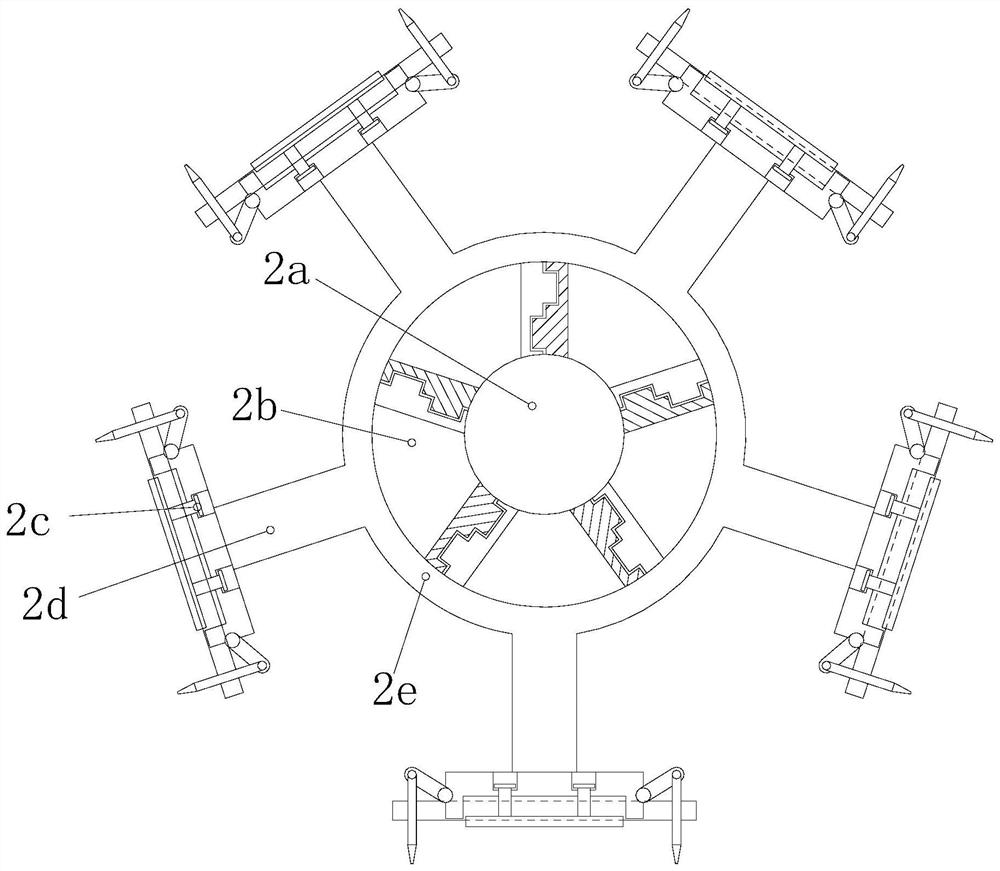

[0025] The flat device 2 is composed of a central shaft 2a, a rotating disk 2b, a flat mechanism 2c, a connecting shaft 2d, and an outer layer connecting shaft 2e. The central shaft 2a is installed in the center of the rotating disk 2b, and the central shaft 2a runs through the rotating disk 2b. The turntable 2b is arranged in the outer layer connecting shaft 2e and fixedly connected with the outer layer connecting shaft 2e. There are five connecting shafts 2d. The connecting shaft 2d is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com